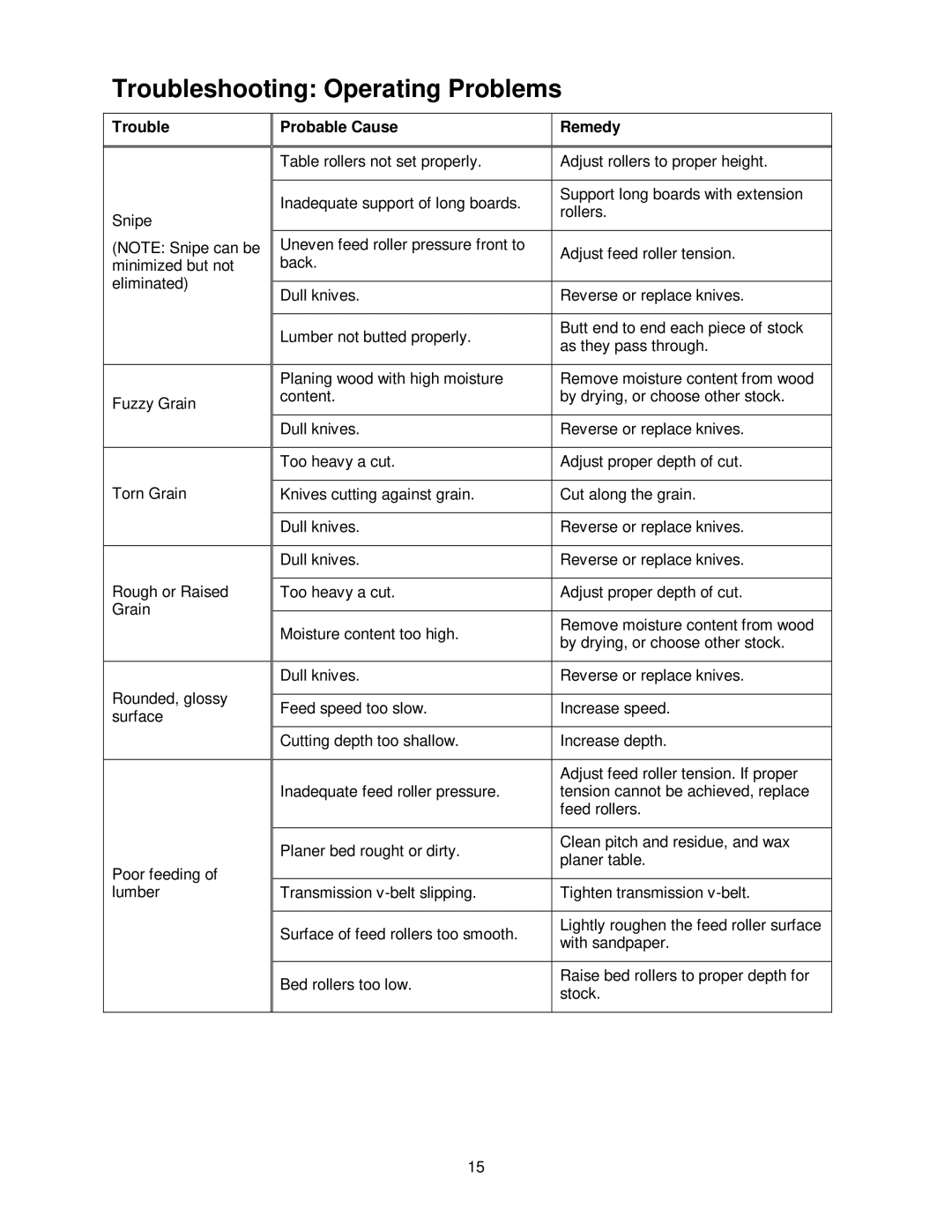

Troubleshooting: Operating Problems

Trouble

Snipe

(NOTE: Snipe can be minimized but not eliminated)

Fuzzy Grain

Torn Grain

Rough or Raised Grain

Rounded, glossy surface

Poor feeding of lumber

Probable Cause | Remedy | |

|

| |

Table rollers not set properly. | Adjust rollers to proper height. | |

|

| |

Inadequate support of long boards. | Support long boards with extension | |

rollers. | ||

| ||

|

| |

Uneven feed roller pressure front to | Adjust feed roller tension. | |

back. | ||

| ||

|

| |

Dull knives. | Reverse or replace knives. | |

|

| |

Lumber not butted properly. | Butt end to end each piece of stock | |

as they pass through. | ||

| ||

|

| |

Planing wood with high moisture | Remove moisture content from wood | |

content. | by drying, or choose other stock. | |

|

| |

Dull knives. | Reverse or replace knives. | |

|

| |

Too heavy a cut. | Adjust proper depth of cut. | |

|

| |

Knives cutting against grain. | Cut along the grain. | |

|

| |

Dull knives. | Reverse or replace knives. | |

|

| |

Dull knives. | Reverse or replace knives. | |

|

| |

Too heavy a cut. | Adjust proper depth of cut. | |

|

| |

Moisture content too high. | Remove moisture content from wood | |

by drying, or choose other stock. | ||

| ||

|

| |

Dull knives. | Reverse or replace knives. | |

|

| |

Feed speed too slow. | Increase speed. | |

|

| |

Cutting depth too shallow. | Increase depth. | |

|

| |

| Adjust feed roller tension. If proper | |

Inadequate feed roller pressure. | tension cannot be achieved, replace | |

| feed rollers. | |

|

| |

Planer bed rought or dirty. | Clean pitch and residue, and wax | |

planer table. | ||

| ||

|

| |

Transmission | Tighten transmission | |

|

| |

Surface of feed rollers too smooth. | Lightly roughen the feed roller surface | |

with sandpaper. | ||

| ||

|

| |

Bed rollers too low. | Raise bed rollers to proper depth for | |

stock. | ||

| ||

|

|

15