Congratulations on the purchase of your new Accent™ Disc Laminator (referred to in this document as the "Laminator"). This Quick Start Guide will describe the

1 Applying the Power | 2 Installing Lamination Ribbons |

2Installing Lamination Ribbons

(continued)

4.Insert the Overlaminate Film in the rear set of hubs inside the Laminator as

shown, keep- ing in mind

that the Laminate will feed from

3Laminating Discs in Stand Alone Operation (continued)

will start heating up to operating temperature. Move the Temperature Control Lever to the desired setting. (The middle setting is recommend- ed initially.) The Ready LED should flash intermittently while the roller is heating. The process should take about

1.Locate the power cord supplied with your Laminator.

2.Place one end of the power cord into the power port located on the rear panel of the Laminator.

3.Plug the power cord into an available outlet. Avoid plugging your Laminator into a battery backup or uninterruptible power supply.

About Lamination Film and Optical Media

Lamination Film for your Optical Disc Laminator is available in both a clear and holographic finish. The Holographic Overlaminate is used as a security feature making your discs easily identifiable as authentic. Holographic Overlaminate is also available with your own design when purchased in quantity. Please contact your dealer for details. Most inkjet printable discs will work well with some adjusting for heat. Because it is impossible to test all types of media, it is highly recommended you purchase a small amount for testing before committing to a large, bulk purchase of media.

If you are having trouble with lamination quality, consider purchasing Accent Certified Media Kits. Kits contain CDs or DVDs that are specifically tested and certified for use with the Accent. These discs are the best possible combination of burnable surface, printable surface and lamination surface. For more information, visit our web store at www.primerastore.com.

1.Press the Access Cover Button to open the Access Cover.

Access Cover

Button

2.Remove the Overlaminate Film and

![]() Supply

Supply

![]()

3.Place the

engage and lock in place with the notches in the

over the top

of the roll and the

notches in

the core will need to face the right- side of the laminator to lock in place with the ribbon drive hub.

5.The white portion of the leading edge of Overlaminate film has an adhesive

coating. Pull it forward as shown,

attaching it to the front

Core towards the front of the laminator over the top to ensure the Overlaminate film is securely attached. When properly loaded the film will feed from over the top of the supply roll in back and will travel over the top of the

3Laminating Discs in Stand Alone Operation

Now that you have successfully loaded the Lamination Film, you are ready to laminate your discs.

1.Turn the Laminator Power Switch to the ON position. Press the Laminate button. The Disc Tray should automatically eject from the Laminator and the Thermal Roller

NOTE: The Laminator will automatically go into 'cool down' mode after 30 minutes of inactivity.

2.Once the READY LED is on and steady, the Laminator is at heat and ready to laminate your discs. You may need to make adjustments to the Laminator heat settings to ensure high quality output. Start with a test lamination to see if any adjustment will need to be made. This is done as follows:

a.Place a disc on the Disc Tray.

b.Press the Laminate Button.

c.The disc will be drawn into the Laminator, laminated and the tray will be ejected.

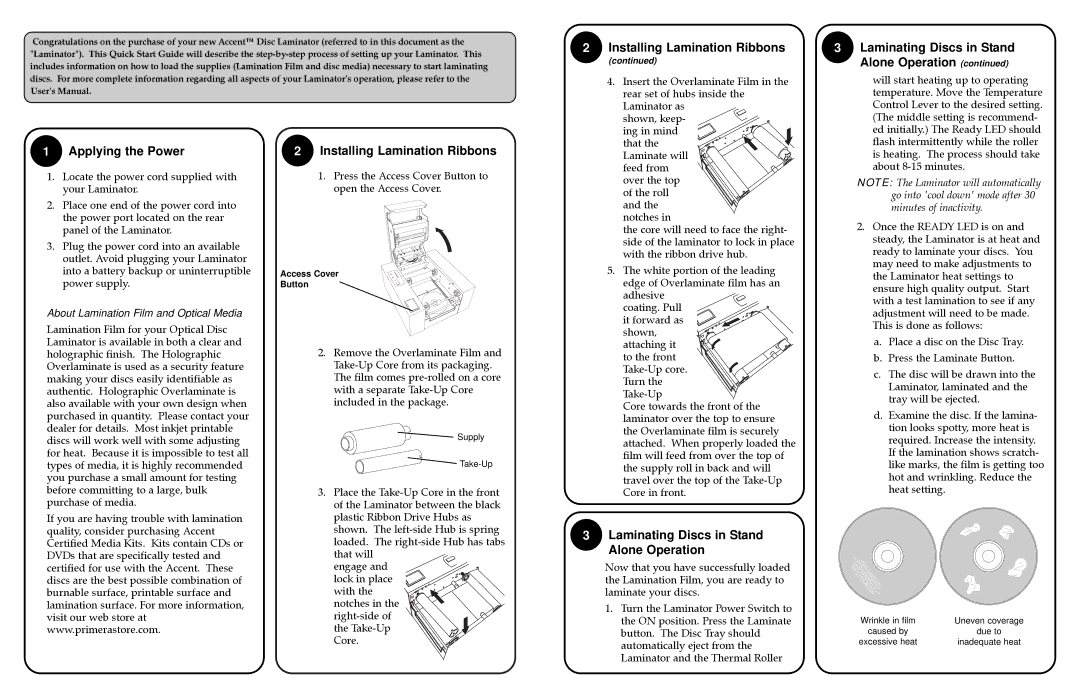

d.Examine the disc. If the lamina- tion looks spotty, more heat is required. Increase the intensity. If the lamination shows scratch- like marks, the film is getting too hot and wrinkling. Reduce the heat setting.

Wrinkle in film | Uneven coverage |

caused by | due to |

excessive heat | inadequate heat |