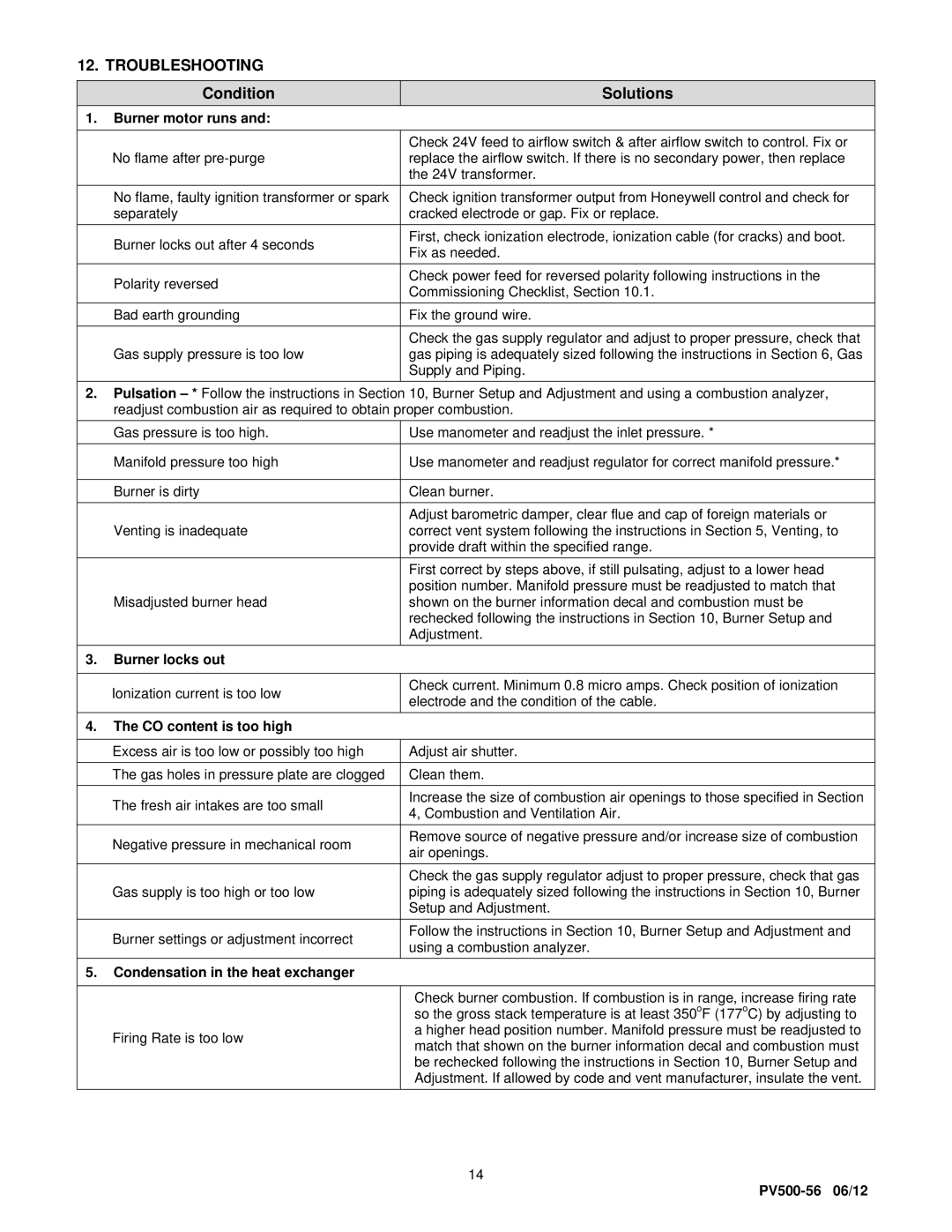

12. TROUBLESHOOTING

Condition | Solutions | |

1. Burner motor runs and: |

| |

| Check 24V feed to airflow switch & after airflow switch to control. Fix or | |

No flame after | replace the airflow switch. If there is no secondary power, then replace | |

| the 24V transformer. | |

No flame, faulty ignition transformer or spark | Check ignition transformer output from Honeywell control and check for | |

separately | cracked electrode or gap. Fix or replace. | |

Burner locks out after 4 seconds | First, check ionization electrode, ionization cable (for cracks) and boot. | |

Fix as needed. | ||

| ||

Polarity reversed | Check power feed for reversed polarity following instructions in the | |

Commissioning Checklist, Section 10.1. | ||

| ||

Bad earth grounding | Fix the ground wire. | |

| Check the gas supply regulator and adjust to proper pressure, check that | |

Gas supply pressure is too low | gas piping is adequately sized following the instructions in Section 6, Gas | |

| Supply and Piping. |

2. Pulsation – * Follow the instructions in Section 10, Burner Setup and Adjustment and using a combustion analyzer, readjust combustion air as required to obtain proper combustion.

Gas pressure is too high. | Use manometer and readjust the inlet pressure. * | |

Manifold pressure too high | Use manometer and readjust regulator for correct manifold pressure.* | |

|

| |

Burner is dirty | Clean burner. | |

| Adjust barometric damper, clear flue and cap of foreign materials or | |

Venting is inadequate | correct vent system following the instructions in Section 5, Venting, to | |

| provide draft within the specified range. | |

| First correct by steps above, if still pulsating, adjust to a lower head | |

| position number. Manifold pressure must be readjusted to match that | |

Misadjusted burner head | shown on the burner information decal and combustion must be | |

| rechecked following the instructions in Section 10, Burner Setup and | |

| Adjustment. | |

3. Burner locks out |

| |

|

| |

Ionization current is too low | Check current. Minimum 0.8 micro amps. Check position of ionization | |

electrode and the condition of the cable. | ||

| ||

4. The CO content is too high |

| |

|

| |

Excess air is too low or possibly too high | Adjust air shutter. | |

The gas holes in pressure plate are clogged | Clean them. | |

The fresh air intakes are too small | Increase the size of combustion air openings to those specified in Section | |

4, Combustion and Ventilation Air. | ||

| ||

Negative pressure in mechanical room | Remove source of negative pressure and/or increase size of combustion | |

air openings. | ||

| ||

| Check the gas supply regulator adjust to proper pressure, check that gas | |

Gas supply is too high or too low | piping is adequately sized following the instructions in Section 10, Burner | |

| Setup and Adjustment. | |

Burner settings or adjustment incorrect | Follow the instructions in Section 10, Burner Setup and Adjustment and | |

using a combustion analyzer. | ||

| ||

5. Condensation in the heat exchanger |

| |

|

| |

| Check burner combustion. If combustion is in range, increase firing rate | |

| so the gross stack temperature is at least 350oF (177oC) by adjusting to | |

Firing Rate is too low | a higher head position number. Manifold pressure must be readjusted to | |

match that shown on the burner information decal and combustion must | ||

| ||

| be rechecked following the instructions in Section 10, Burner Setup and | |

| Adjustment. If allowed by code and vent manufacturer, insulate the vent. |

14