LUBRICATION

Although all

DISCONNECT TOOL FROM POWER SOURCE.

DISCONNECT TOOL FROM POWER SOURCE.

1.Remove the saw blade to prevent accidental contact when checking the oil level.

2.Adjust the saw for the maximum depth of cut and 45 degree bevel cut. Firmly tighten all knobs.

3.Connect the power to the tool. Turn the saw “ON” and run it for approximately two minutes.

DISCONNECT TOOL FROM POWER SOURCE.

DISCONNECT TOOL FROM POWER SOURCE.

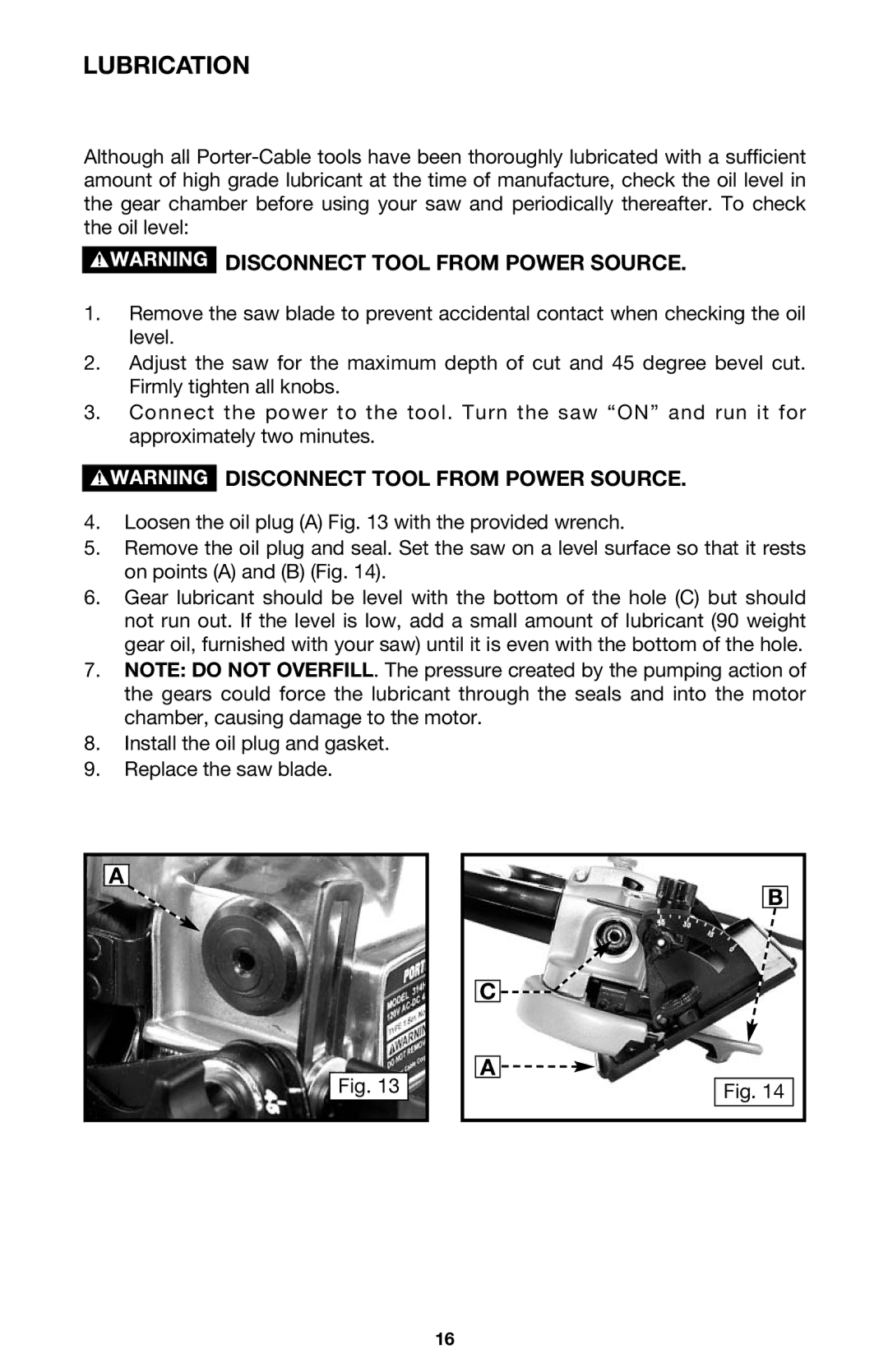

4.Loosen the oil plug (A) Fig. 13 with the provided wrench.

5.Remove the oil plug and seal. Set the saw on a level surface so that it rests on points (A) and (B) (Fig. 14).

6.Gear lubricant should be level with the bottom of the hole (C) but should not run out. If the level is low, add a small amount of lubricant (90 weight gear oil, furnished with your saw) until it is even with the bottom of the hole.

7.NOTE: DO NOT OVERFILL. The pressure created by the pumping action of the gears could force the lubricant through the seals and into the motor chamber, causing damage to the motor.

8.Install the oil plug and gasket.

9.Replace the saw blade.

A

Fig. 13

C![]()

![]()

![]()

![]()

A ![]()

B

Fig. 14

16