1005-2005 specifications

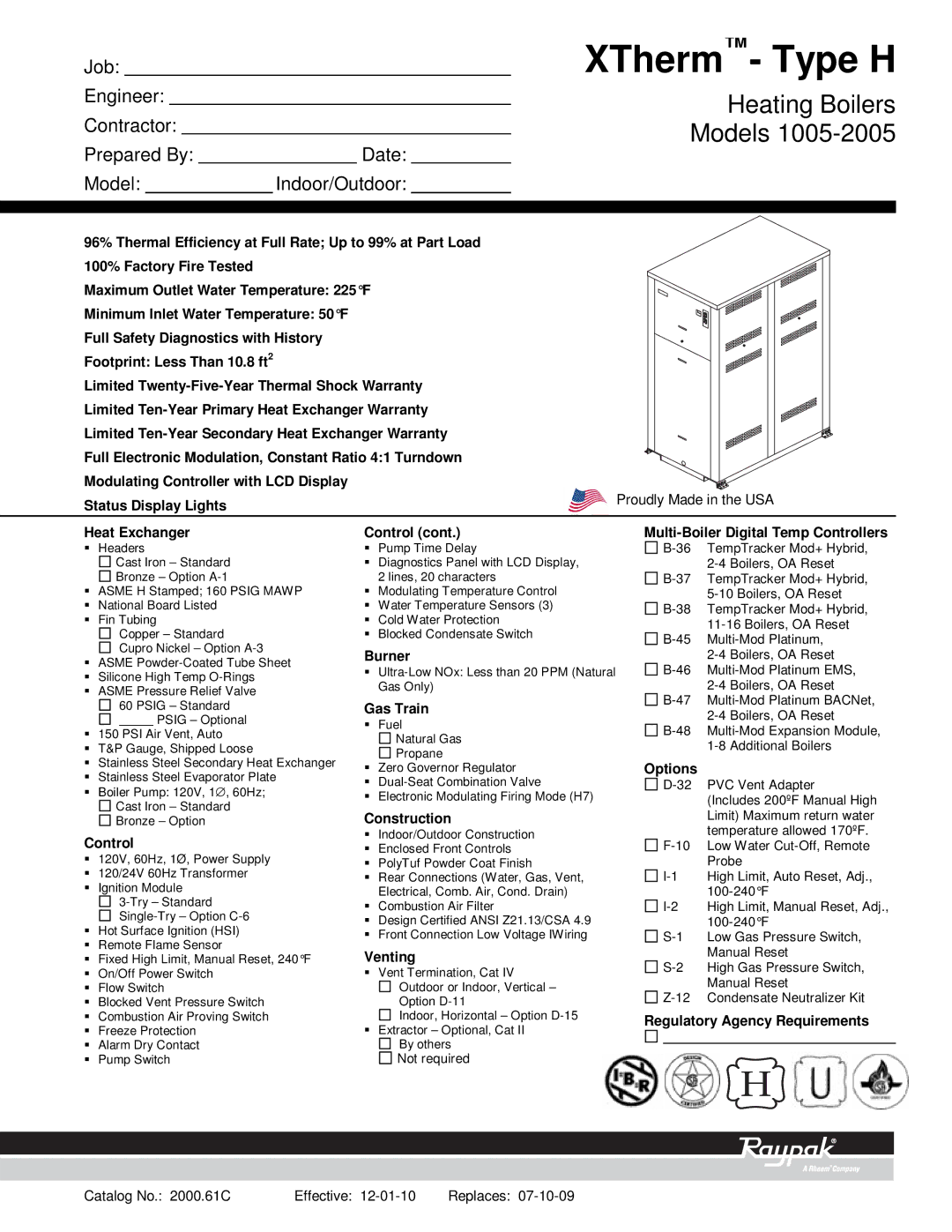

Raypak has long been a trusted name in the heating equipment industry, and its 1005-2005 series of boilers exemplifies the company’s commitment to quality and innovation. Designed for both residential and commercial applications, these boilers offer an impressive combination of efficiency, reliability, and advanced features that appeal to a wide range of users.One of the standout features of the Raypak 1005-2005 series is its exceptional efficiency ratings. The boilers incorporate sophisticated heat exchanger technology that ensures maximum heat transfer while minimizing energy consumption. This not only translates to lower utility bills for homeowners and businesses but also meets and exceeds stringent environmental regulations.

The Raypak 1005-2005 series is equipped with a fully modulating burner system, which allows for precise control over heating output. This technology adapts to the real-time demands of the system, ensuring that energy is only used when needed. As a result, users can enjoy a comfortable environment without wasting energy, making these boilers an environmentally responsible choice.

Another significant feature of the Raypak 1005-2005 series is its durability. Built with high-grade materials and advanced engineering practices, these boilers are designed to withstand the rigors of daily use. Their robust construction also makes maintenance more straightforward, ensuring long-lasting performance and reliability.

Performance monitoring is also a key characteristic of the Raypak 1005-2005 series. The boilers come equipped with digital controls that allow users to monitor performance metrics and service requirements. This real-time data enables proactive maintenance, reducing downtime and prolonging the life of the unit.

Safety is a top priority for Raypak, and the 1005-2005 series features multiple safety mechanisms, including flame supervision, over-temperature protection, and pressure relief systems. These safeguards provide users with peace of mind, knowing that their heating system operates within safe parameters.

In summary, the Raypak 1005-2005 series represents a top-tier solution for heating needs. Its efficiency, advanced burner technology, durability, performance monitoring, and safety features make it an ideal choice for anyone looking to enhance their heating systems. Whether for residential or commercial use, Raypak has designed a boiler that not only meets but exceeds user expectations, making it a dependable investment for years to come.