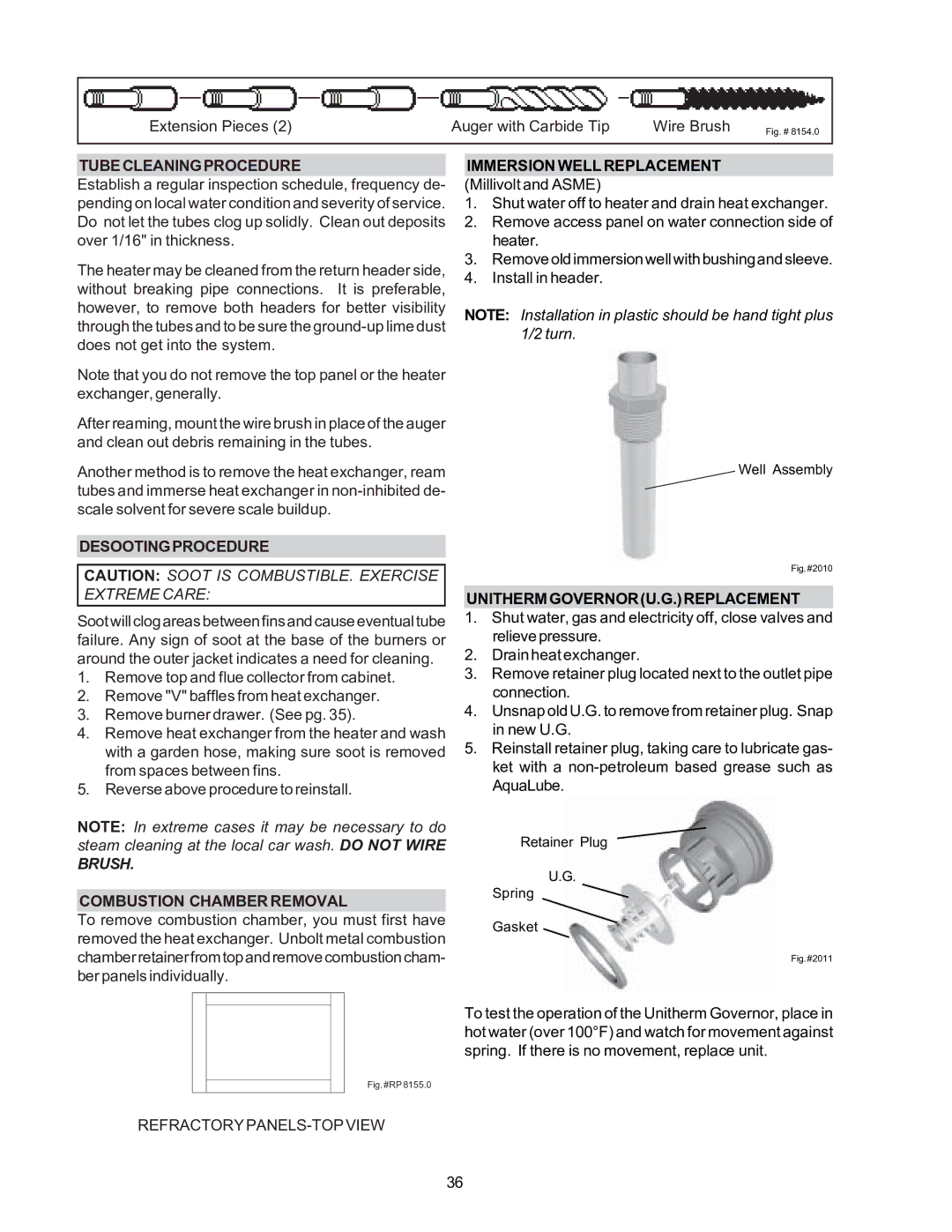

Extension Pieces (2) | Auger with Carbide Tip | Wire Brush | Fig. # 8154.0 |

|

|

|

|

TUBECLEANINGPROCEDURE

Establish a regular inspection schedule, frequency de- pending on local water condition and severity of service. Do not let the tubes clog up solidly. Clean out deposits over 1/16" in thickness.

The heater may be cleaned from the return header side, without breaking pipe connections. It is preferable, however, to remove both headers for better visibility through the tubes and to be sure the

Note that you do not remove the top panel or the heater exchanger, generally.

After reaming, mount the wire brush in place of the auger and clean out debris remaining in the tubes.

Another method is to remove the heat exchanger, ream tubes and immerse heat exchanger in

DESOOTINGPROCEDURE

CAUTION: SOOT IS COMBUSTIBLE. EXERCISE EXTREME CARE:

Soot will clog areas between fins and cause eventual tube failure. Any sign of soot at the base of the burners or around the outer jacket indicates a need for cleaning.

1.Remove top and flue collector from cabinet.

2.Remove "V" baffles from heat exchanger.

3.Remove burner drawer. (See pg. 35).

4.Remove heat exchanger from the heater and wash with a garden hose, making sure soot is removed from spaces between fins.

5.Reverse above procedure to reinstall.

NOTE: In extreme cases it may be necessary to do steam cleaning at the local car wash. DO NOT WIRE

BRUSH.

COMBUSTION CHAMBER REMOVAL

To remove combustion chamber, you must first have removed the heat exchanger. Unbolt metal combustion chamberretainerfromtopandremovecombustioncham- ber panels individually.

IMMERSION WELL REPLACEMENT

(Millivolt and ASME)

1.Shut water off to heater and drain heat exchanger.

2.Remove access panel on water connection side of heater.

3.Remove old immersion well with bushing and sleeve.

4.Install in header.

NOTE: Installation in plastic should be hand tight plus 1/2 turn.

Well Assembly

Fig. #2010

UNITHERM GOVERNOR (U.G.) REPLACEMENT

1.Shut water, gas and electricity off, close valves and relieve pressure.

2.Drain heat exchanger.

3.Remove retainer plug located next to the outlet pipe connection.

4.Unsnap old U.G. to remove from retainer plug. Snap in new U.G.

5.Reinstall retainer plug, taking care to lubricate gas- ket with a

Retainer Plug

U.G.

Spring

Gasket

Fig. #2011

To test the operation of the Unitherm Governor, place in hot water (over 100°F) and watch for movement against spring. If there is no movement, replace unit.

Fig. #RP 8155.0

REFRACTORY

36