2

Fig.2

Fig.1

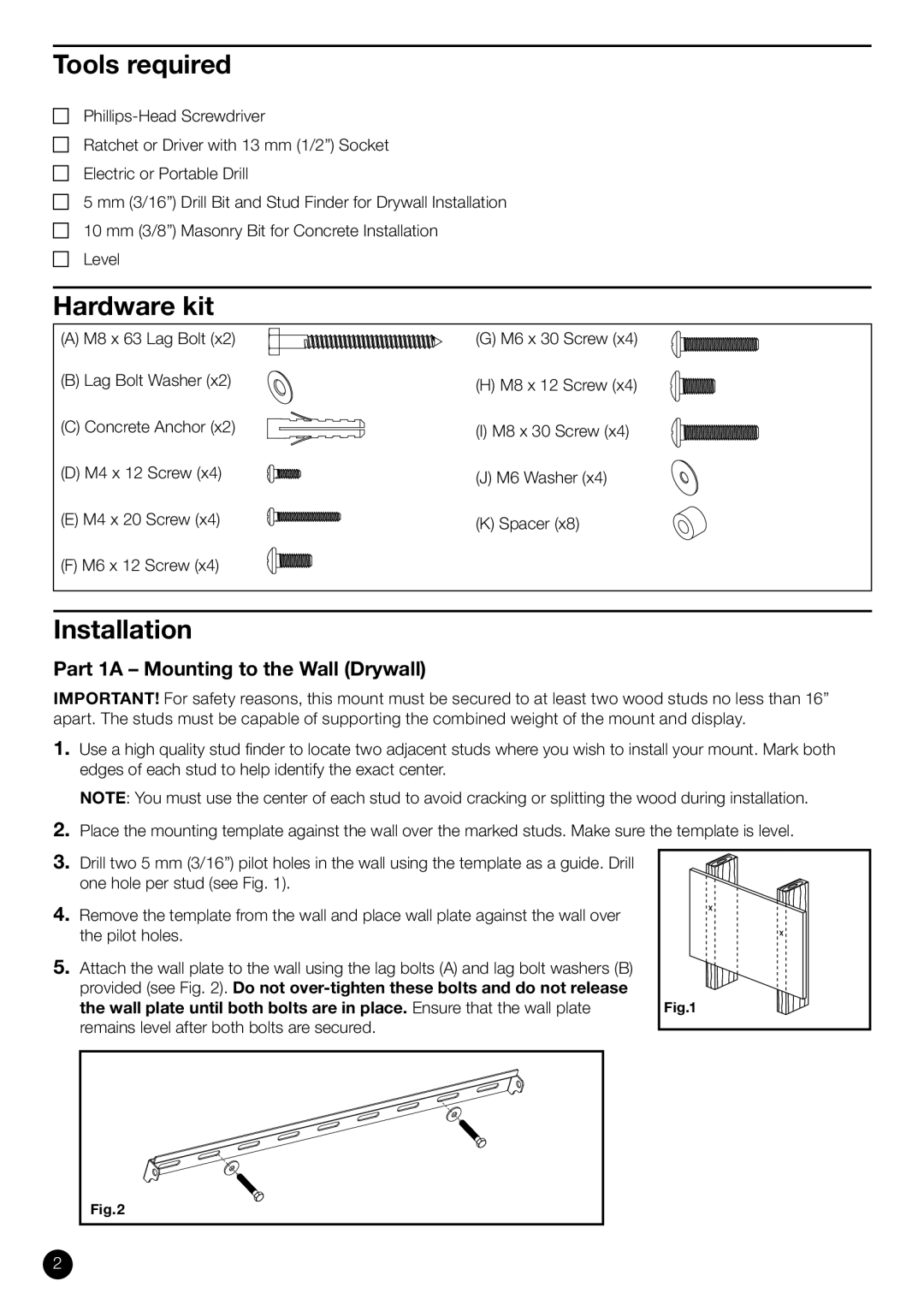

4. Remove the template from the wall and place wall plate against the wall over the pilot holes.

5. Attach the wall plate to the wall using the lag bolts (A) and lag bolt washers (B) provided (see Fig. 2). Do not over-tighten these bolts and do not release the wall plate until both bolts are in place. Ensure that the wall plate remains level after both bolts are secured.

(F) M6 x 12 Screw (x4)

Installation

Part 1A – Mounting to the Wall (Drywall)

IMPORTANT! For safety reasons, this mount must be secured to at least two wood studs no less than 16” apart. The studs must be capable of supporting the combined weight of the mount and display.

1. Use a high quality stud fi nder to locate two adjacent studs where you wish to install your mount. Mark both edges of each stud to help identify the exact center.

NOTE: You must use the center of each stud to avoid cracking or splitting the wood during installation.

2. Place the mounting template against the wall over the marked studs. Make sure the template is level.

3. Drill two 5 mm (3/16”) pilot holes in the wall using the template as a guide. Drill

one hole per stud (see Fig. 1).

(K) Spacer (x8)

(E) M4 x 20 Screw (x4)

(J) M6 Washer (x4)

(D) M4 x 12 Screw (x4)

(I) M8 x 30 Screw (x4)

(C) Concrete Anchor (x2)

(H) M8 x 12 Screw (x4)

(A) M8 x 63 Lag Bolt (x2)

(B) Lag Bolt Washer (x2)

(G) M6 x 30 Screw (x4)

Hardware kit

Tools required

Ratchet or Driver with 13 mm (1/2”) Socket

Electric or Portable Drill

5 mm (3/16”) Drill Bit and Stud Finder for Drywall Installation 10 mm (3/8”) Masonry Bit for Concrete Installation

Level