OPERATION

Angle Cutting (Bevel Cutting)

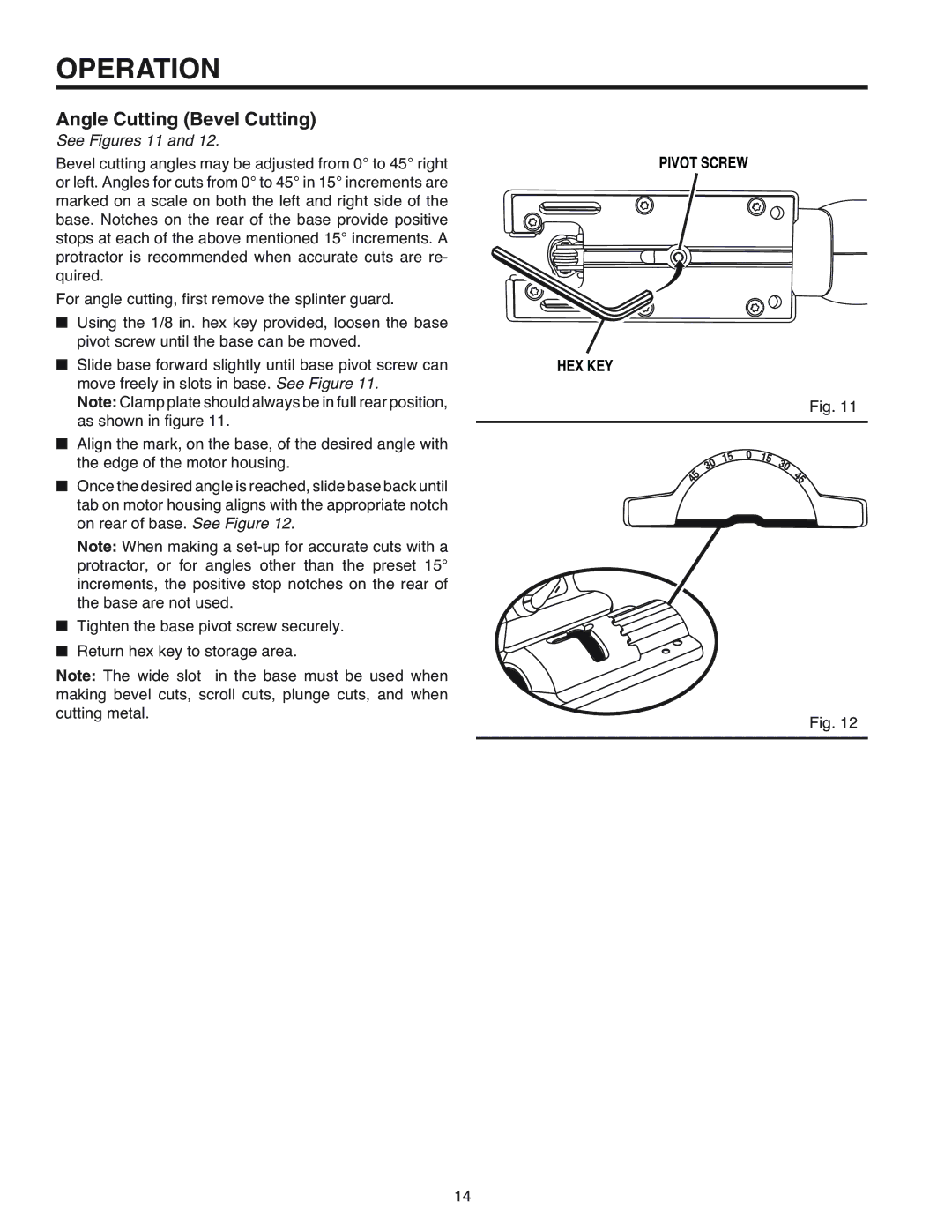

See Figures 11 and 12.

Bevel cutting angles may be adjusted from 0° to 45° right | PIVOT SCREW | |

or left. Angles for cuts from 0° to 45° in 15° increments are |

| |

marked on a scale on both the left and right side of the |

| |

base. Notches on the rear of the base provide positive |

| |

stops at each of the above mentioned 15° increments. A |

| |

protractor is recommended when accurate cuts are re- |

| |

quired. |

| |

For angle cutting, first remove the splinter guard. |

| |

■ Using the 1/8 in. hex key provided, loosen the base |

| |

pivot screw until the base can be moved. |

| |

■ Slide base forward slightly until base pivot screw can | HEX KEY | |

move freely in slots in base. See Figure 11. |

| |

Note: Clamp plate should always be in full rear position, | Fig. 11 | |

as shown in figure 11. | ||

| ||

■ Align the mark, on the base, of the desired angle with |

| |

the edge of the motor housing. |

| |

■ Once the desired angle is reached, slide base back until |

| |

tab on motor housing aligns with the appropriate notch |

| |

on rear of base. See Figure 12. |

| |

Note: When making a |

| |

protractor, or for angles other than the preset 15° |

| |

increments, the positive stop notches on the rear of |

| |

the base are not used. |

| |

■ Tighten the base pivot screw securely. |

| |

■ Return hex key to storage area. |

| |

Note: The wide slot in the base must be used when |

| |

making bevel cuts, scroll cuts, plunge cuts, and when |

| |

cutting metal. | Fig. 12 | |

|

14