OPERATION

Orbital Motion

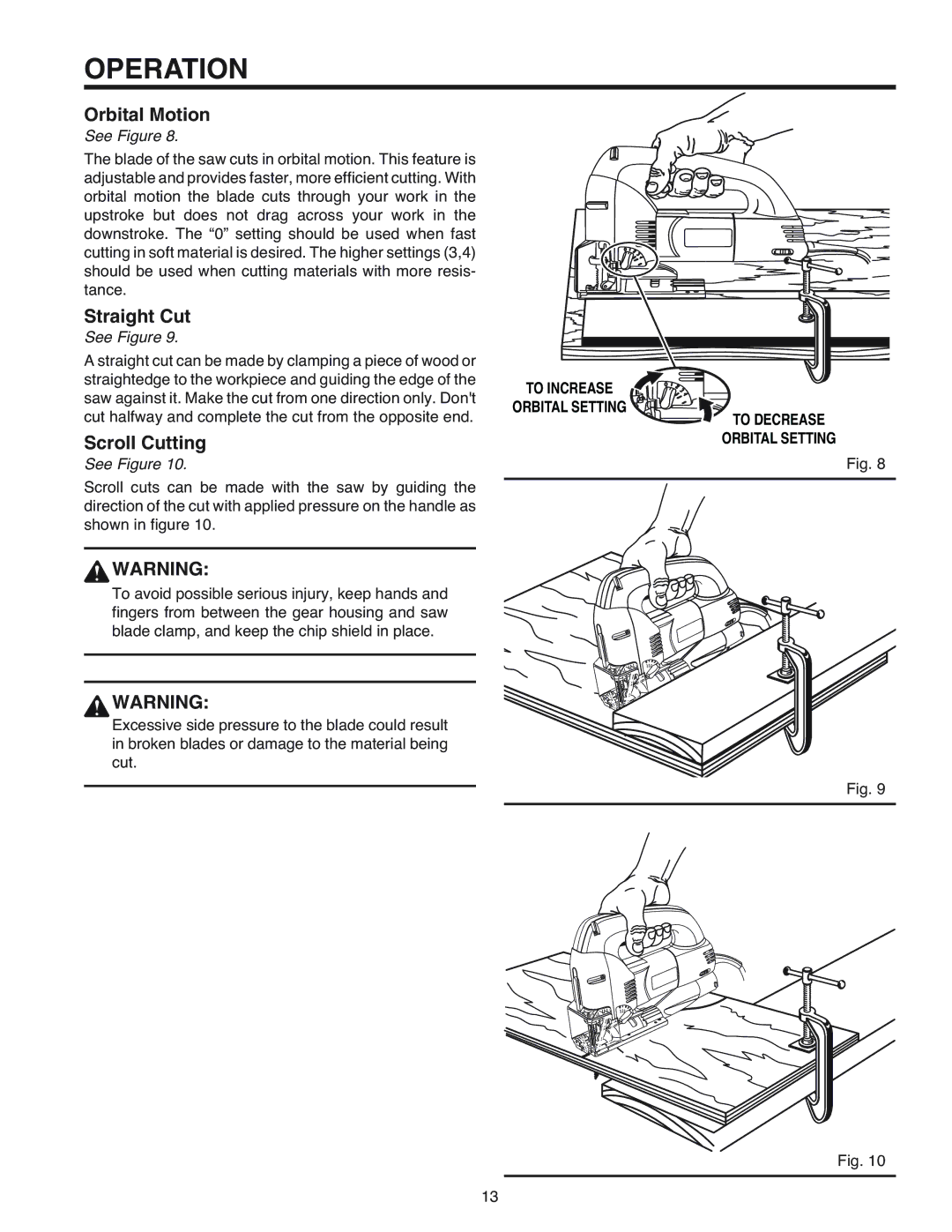

See Figure 8.

The blade of the saw cuts in orbital motion. This feature is adjustable and provides faster, more efficient cutting. With orbital motion the blade cuts through your work in the upstroke but does not drag across your work in the downstroke. The “0” setting should be used when fast cutting in soft material is desired. The higher settings (3,4) should be used when cutting materials with more resis- tance.

Straight Cut

See Figure 9.

A straight cut can be made by clamping a piece of wood or straightedge to the workpiece and guiding the edge of the saw against it. Make the cut from one direction only. Don't cut halfway and complete the cut from the opposite end.

Scroll Cutting

See Figure 10.

Scroll cuts can be made with the saw by guiding the direction of the cut with applied pressure on the handle as shown in figure 10.

![]() WARNING:

WARNING:

To avoid possible serious injury, keep hands and fingers from between the gear housing and saw blade clamp, and keep the chip shield in place.

![]() WARNING:

WARNING:

Excessive side pressure to the blade could result in broken blades or damage to the material being cut.

TO INCREASE

ORBITAL SETTING

TO DECREASE

ORBITAL SETTING

Fig. 8

Fig. 9

Fig. 10

13