MAINTENANCE

CHUCK REMOVAL

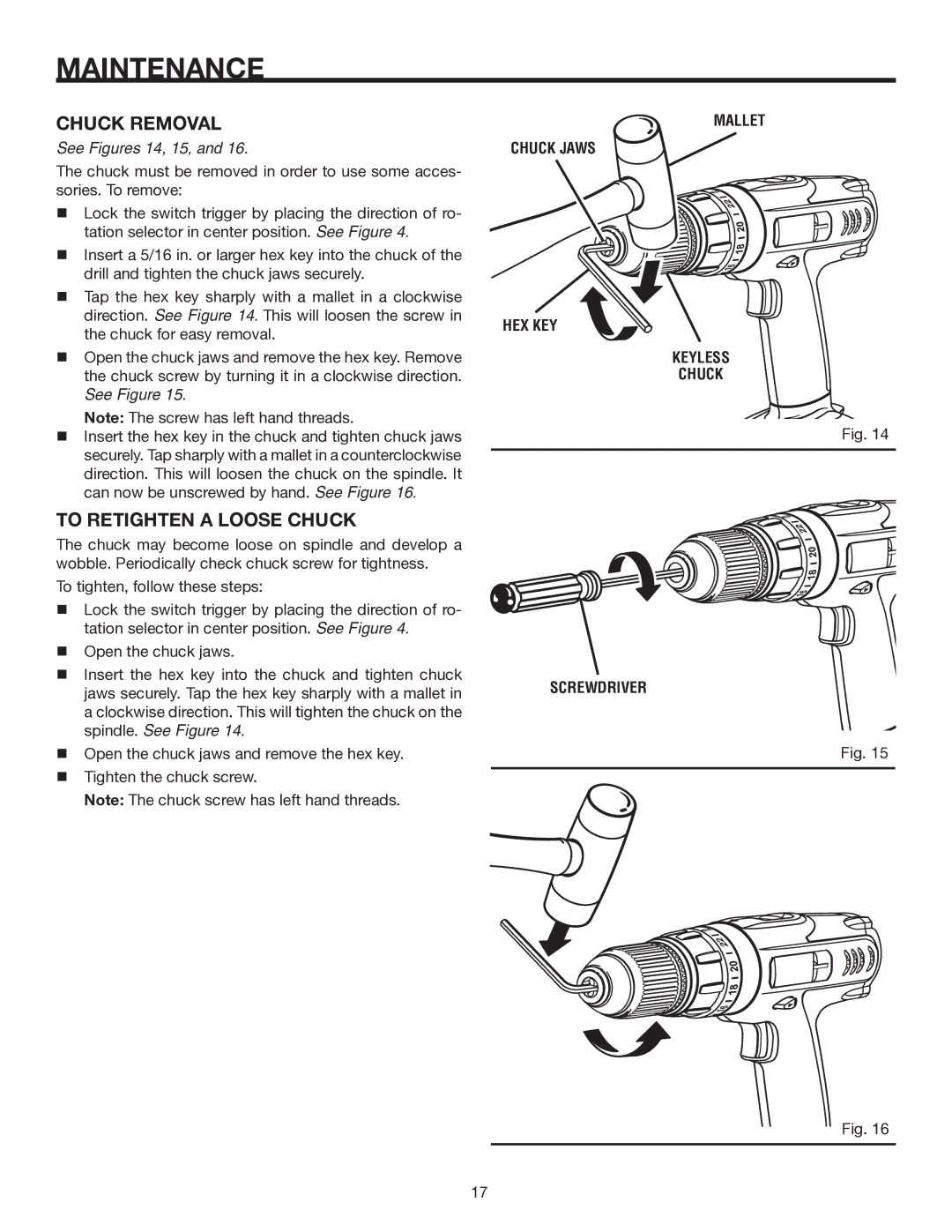

See Figures 14, 15, and 16.

The chuck must be removed in order to use some acces- sories. To remove:

nLock the switch trigger by placing the direction of ro- tation selector in center position. See Figure 4.

nInsert a 5/16 in. or larger hex key into the chuck of the drill and tighten the chuck jaws securely.

nTap the hex key sharply with a mallet in a clockwise direction. See Figure 14. This will loosen the screw in the chuck for easy removal.

nOpen the chuck jaws and remove the hex key. Remove the chuck screw by turning it in a clockwise direction.

See Figure 15.

Note: The screw has left hand threads.

nInsert the hex key in the chuck and tighten chuck jaws securely. Tap sharply with a mallet in a counterclockwise direction. This will loosen the chuck on the spindle. It can now be unscrewed by hand. See Figure 16.

TO RETIGHTEN A LOOSE CHUCK

The chuck may become loose on spindle and develop a wobble. Periodically check chuck screw for tightness.

To tighten, follow these steps:

nLock the switch trigger by placing the direction of ro- tation selector in center position. See Figure 4.

nOpen the chuck jaws.

nInsert the hex key into the chuck and tighten chuck jaws securely. Tap the hex key sharply with a mallet in a clockwise direction. This will tighten the chuck on the spindle. See Figure 14.

nOpen the chuck jaws and remove the hex key.

nTighten the chuck screw.

Note: The chuck screw has left hand threads.

MALLET

CHUCK JAWS

HEX KEY

KEYLESS

CHUCK

Fig. 14

SCREWDRIVER

Fig. 15

Fig. 16

17