OPERATION

SELECTING DRIVE, DRILL, OR HAMMER | 3 | |

SETTING | ||

| ||

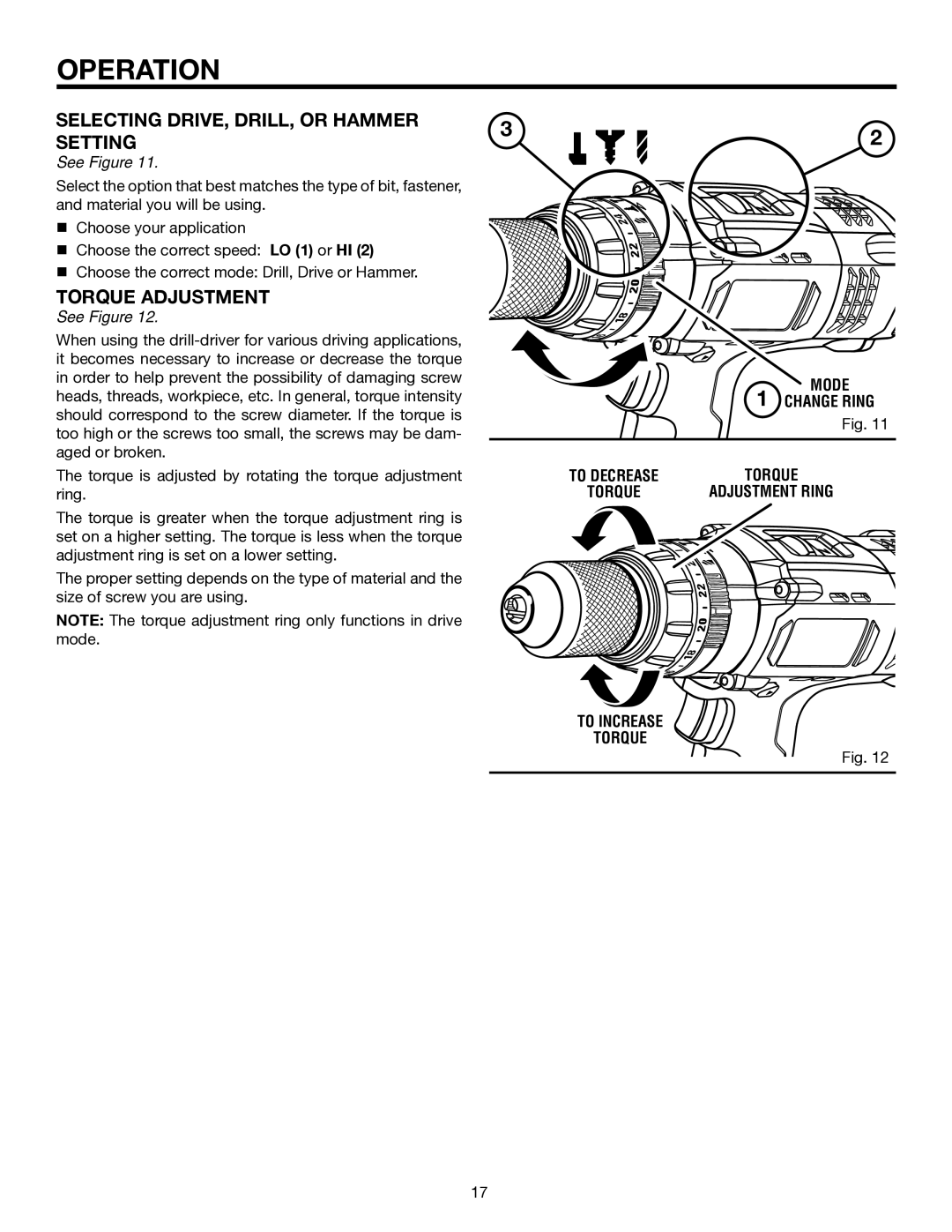

See Figure 11. |

|

Select the option that best matches the type of bit, fastener, and material you will be using.

Choose your application

Choose the correct speed: LO (1) or HI (2)

Choose the correct mode: Drill, Drive or Hammer.

TORQUE ADJUSTMENT

See Figure 12.

When using the

2

MODE

1CHANGE RING Fig. 11

The torque is adjusted by rotating the torque adjustment ring.

The torque is greater when the torque adjustment ring is set on a higher setting. The torque is less when the torque adjustment ring is set on a lower setting.

The proper setting depends on the type of material and the size of screw you are using.

NOTE: The torque adjustment ring only functions in drive mode.

TO DECREASE | TORQUE |

TORQUE | ADJUSTMENT RING |

TO INCREASE

TORQUE

Fig. 12

17