MAINTENANCE

CHUCK REMOVAL

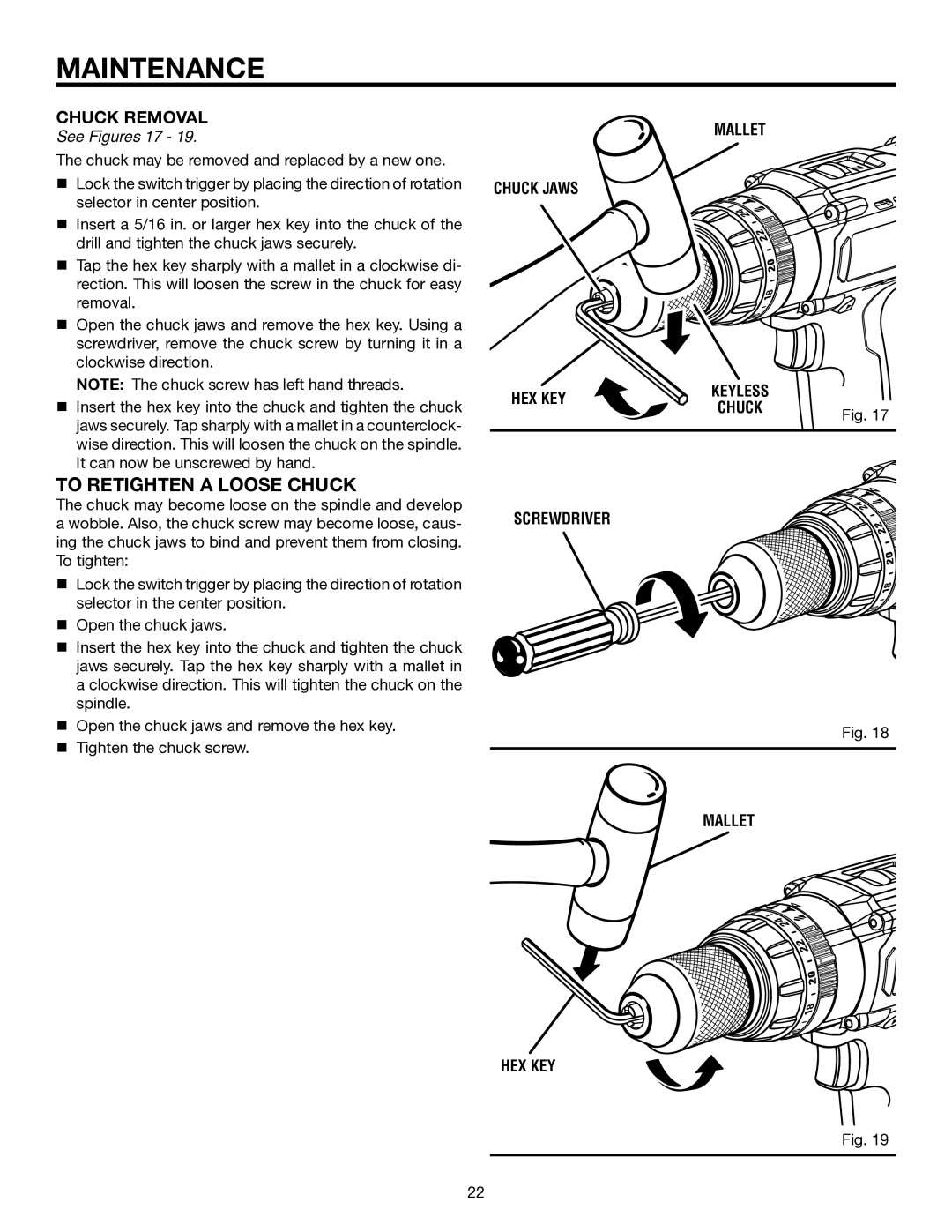

See Figures 17 - 19.

The chuck may be removed and replaced by a new one.

Lock the switch trigger by placing the direction of rotation selector in center position.

Insert a 5/16 in. or larger hex key into the chuck of the drill and tighten the chuck jaws securely.

Tap the hex key sharply with a mallet in a clockwise di- rection. This will loosen the screw in the chuck for easy removal.

Open the chuck jaws and remove the hex key. Using a screwdriver, remove the chuck screw by turning it in a clockwise direction.

NOTE: The chuck screw has left hand threads.

Insert the hex key into the chuck and tighten the chuck jaws securely. Tap sharply with a mallet in a counterclock- wise direction. This will loosen the chuck on the spindle. It can now be unscrewed by hand.

TO RETIGHTEN A LOOSE CHUCK

The chuck may become loose on the spindle and develop a wobble. Also, the chuck screw may become loose, caus- ing the chuck jaws to bind and prevent them from closing. To tighten:

Lock the switch trigger by placing the direction of rotation selector in the center position.

Open the chuck jaws.

Insert the hex key into the chuck and tighten the chuck jaws securely. Tap the hex key sharply with a mallet in a clockwise direction. This will tighten the chuck on the spindle.

Open the chuck jaws and remove the hex key.

Tighten the chuck screw.

MALLET

CHUCK JAWS

HEX KEY | KEYLESS |

| |

CHUCK | Fig. 17 | ||

| |||

|

|

SCREWDRIVER

Fig. 18

MALLET

HEX KEY

Fig. 19

22