FEATURES

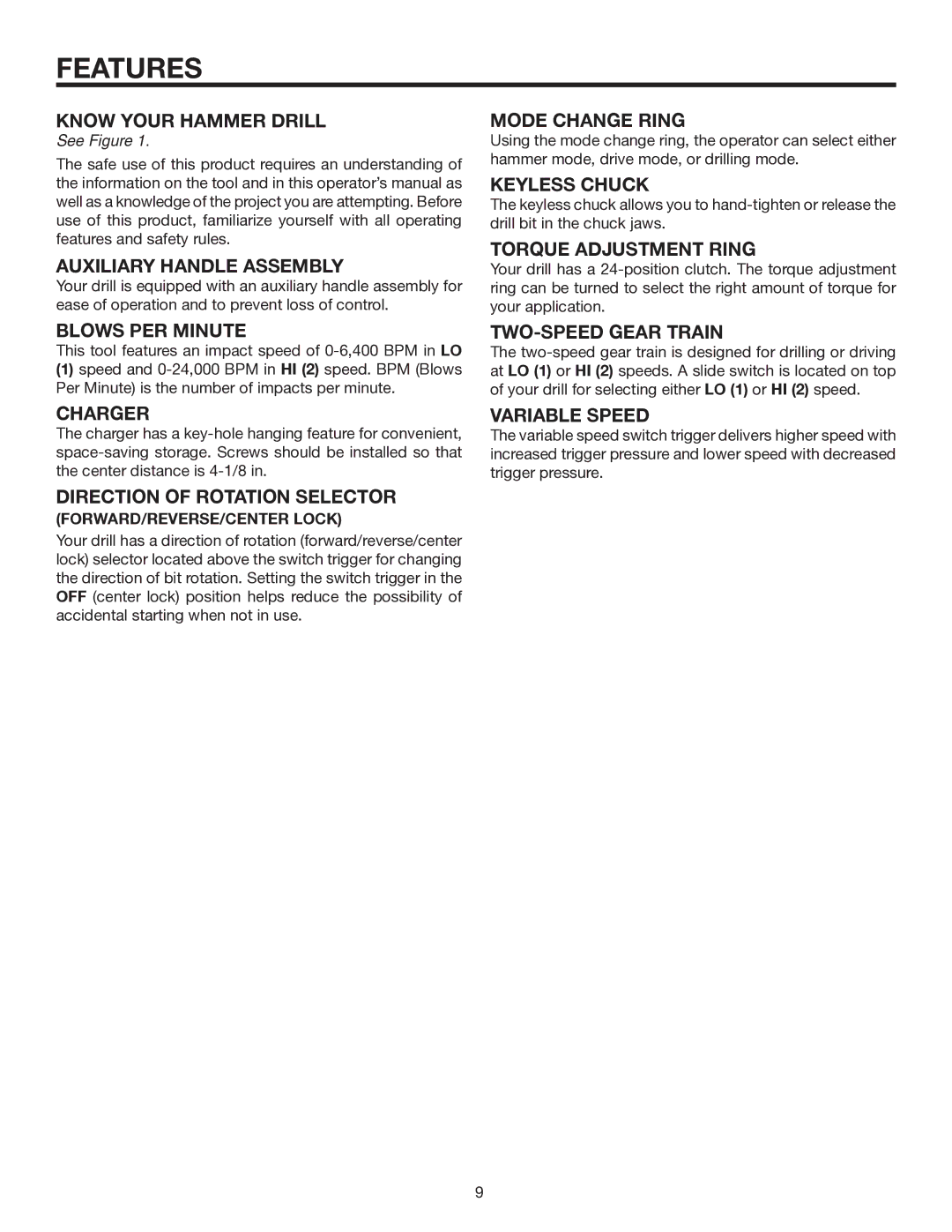

KNOW YOUR HAMMER DRILL

See Figure 1.

The safe use of this product requires an understanding of the information on the tool and in this operator’s manual as well as a knowledge of the project you are attempting. Before use of this product, familiarize yourself with all operating features and safety rules.

AUXILIARY HANDLE ASSEMBLY

Your drill is equipped with an auxiliary handle assembly for ease of operation and to prevent loss of control.

BLOWS PER MINUTE

This tool features an impact speed of

(1)speed and

CHARGER

The charger has a

DIRECTION OF ROTATION SELECTOR

(FORWARD/REVERSE/CENTER LOCK)

Your drill has a direction of rotation (forward/reverse/center lock) selector located above the switch trigger for changing the direction of bit rotation. Setting the switch trigger in the OFF (center lock) position helps reduce the possibility of accidental starting when not in use.

MODE CHANGE RING

Using the mode change ring, the operator can select either hammer mode, drive mode, or drilling mode.

KEYLESS CHUCK

The keyless chuck allows you to

TORQUE ADJUSTMENT RING

Your drill has a

TWO-SPEED GEAR TRAIN

The

VARIABLE SPEED

The variable speed switch trigger delivers higher speed with increased trigger pressure and lower speed with decreased trigger pressure.

9