TO CHECK THE MOWER FOR ALIGNMENT – Your mower is designed to produce the perfectly flat cut that is required for a top quality green. Ridging or stepping between cuts means that the height of cut is unevenly set or more likely, that the mower is “out of square” – That is, the rear roller is not perfectly in line with the cutting edge of the bottom blade. This condition can be brought about by transport of the mower or undue stress caused by bumping while moving from the equipment shed onto the green.

Lay the mower back on the handle.

Chalk the thin front edge of the bottom blade about 6” of is length at both ends.

With the front roller remaining in approximately its normal height setting, “sight” the bottom of the front roller relative to the chalked cutting edge of the blade.

Adjust the front roller into exact alignment with the cutting edge, continually sighting while adjustment proceeds. Lock the roller and recheck.

Now use your height setting bar as an aligning tool by placing the bar against the front roller and the rear roller on the extreme LEFT HAND SIDE. (Chain Cover Side)

Adjust the setting bar screw so that it just contacts the bottom blade cutting edge.

Test the right hand side of the rollers with the same setting, and adjust the rear roller up or down until the same screw contact is achieved on the blade.

As the movement of the rear drum could affect the original L.H.S. setting slightly, reset the screw at the L.H.S. and recheck the R.H.S.

All elements of your machine will not be in perfect alignment. After tightening all adjustments a final check should be made.

The required height of cut can now be checked and set in the normal manner.

While the procedure may seem complicated it is in fact very simple to perform and can be carried out in less than 15 minutes. The sighting is easy and accurate because it is done from the front roller which is nearest to the operator. A machine that is “true” will pay dividends by precision cutting of your green.

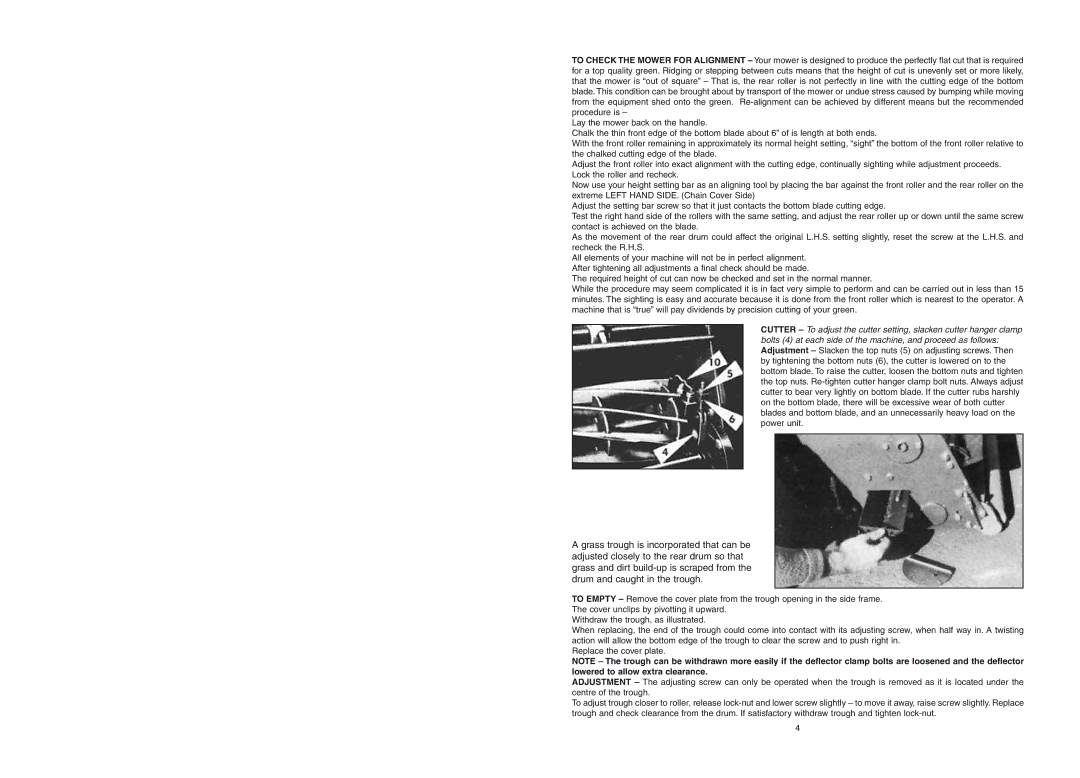

CUTTER – To adjust the cutter setting, slacken cutter hanger clamp bolts (4) at each side of the machine, and proceed as follows: Adjustment – Slacken the top nuts (5) on adjusting screws. Then by tightening the bottom nuts (6), the cutter is lowered on to the bottom blade. To raise the cutter, loosen the bottom nuts and tighten the top nuts.

A grass trough is incorporated that can be adjusted closely to the rear drum so that grass and dirt

TO EMPTY – Remove the cover plate from the trough opening in the side frame. The cover unclips by pivotting it upward.

Withdraw the trough, as illustrated.

When replacing, the end of the trough could come into contact with its adjusting screw, when half way in. A twisting action will allow the bottom edge of the trough to clear the screw and to push right in.

Replace the cover plate.

NOTE – The trough can be withdrawn more easily if the deflector clamp bolts are loosened and the deflector lowered to allow extra clearance.

ADJUSTMENT – The adjusting screw can only be operated when the trough is removed as it is located under the centre of the trough.

To adjust trough closer to roller, release

4