FUEL HANDLING

Fuel mixture

NOTE!

The machine is fitted with a

!WARNING!

Always provide good ventilation when handling fuel.

Petrol

NOTE!

Always use an

•The lowest recommended octane

rating is 90. If you run the engine on a petrol with a lower octane rating than 90

Mixture

•Always mix petrol and oil in a clean container intended for petrol.

•Always start by filling half the quantity of petrol required. Then add the entire oil quantity. Mix (shake) the fuel mixture. Fill the remaining quantity of petrol.

•Mix (shake) the fuel mixture carefully before filling in the machine‘s fuel tank.

•Do not mix more than max. one month’s supply of fuel.

•If the machine is not used for a long period of time, the fuel tank should be emptied and cleaned.

!WARNING!

The catalytic converter muffler gets very hot during and after use. This also applies during idling. Be aware of the fire hazard, especially when handling the saw near flammable substances or vapours.

Fuelling

!WARNING!

The following precautions reduce the risk of fire:

Do not smoke or place any sources of heat in the vicinity of the fuel. Never refuel when the engine is running. Always stop the engine and let it cool for a few minutes before refuelling. Open the fuel cap slowly when fuelling so that any over pressure is released slowly. Tighten the fuel cap carefully after refuelling. Always move the machine from the fuelling place before starting.

breakdown.

•When working at continuous high revs a higher octane rating is recommended.

Two-stroke oil

•For the best results use HUSQVARNA

Mixing ratio 1:50 (2%).

•If HUSQVARNA

Mixing ratio: 1:33 (3%).

•Never use

•Never use oil intended of

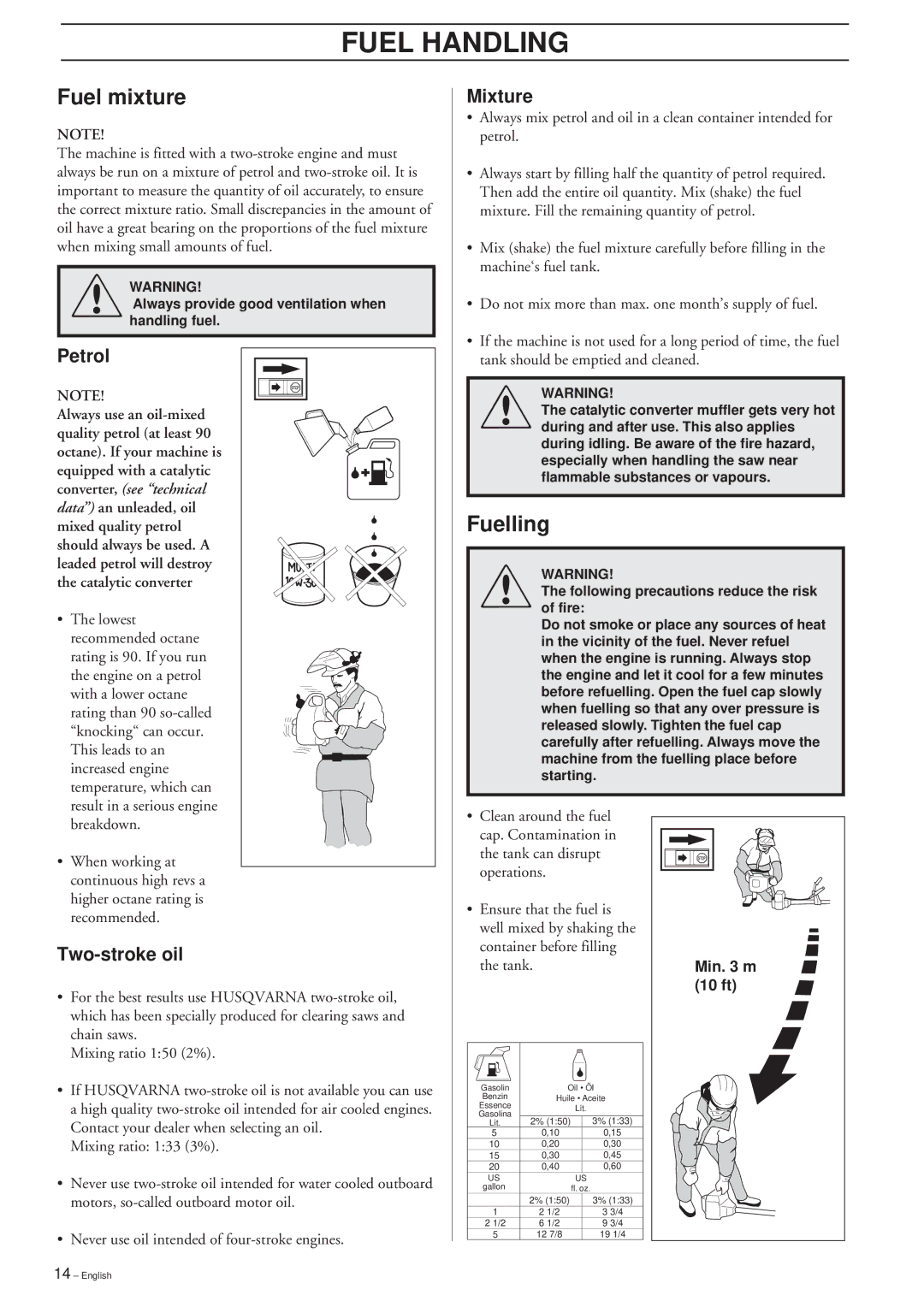

•Clean around the fuel cap. Contamination in the tank can disrupt operations.

•Ensure that the fuel is well mixed by shaking the container before filling the tank.

Gasolin | Oil • Öl | ||

Benzin | Huile • Aceite | ||

Essence |

| Lit. | |

Gasolina |

| ||

2% (1:50) | 3% (1:33) | ||

Lit. | |||

5 | 0,10 | 0,15 | |

10 | 0,20 | 0,30 | |

15 | 0,30 | 0,45 | |

20 | 0,40 | 0,60 | |

US |

| US | |

gallon |

| fl. oz. | |

| 2% (1:50) | 3% (1:33) | |

1 | 2 1/2 | 3 3/4 | |

2 1/2 | 6 1/2 | 9 3/4 | |

5 | 12 7/8 | 19 1/4 | |

Min. 3 m |

(10 ft) |

14 – English