An Ideal Work Flow for Digitalization

The rapid transition of prepress operations to

Advanced Digital Technology To Boost Productivity

From prepress directly to the

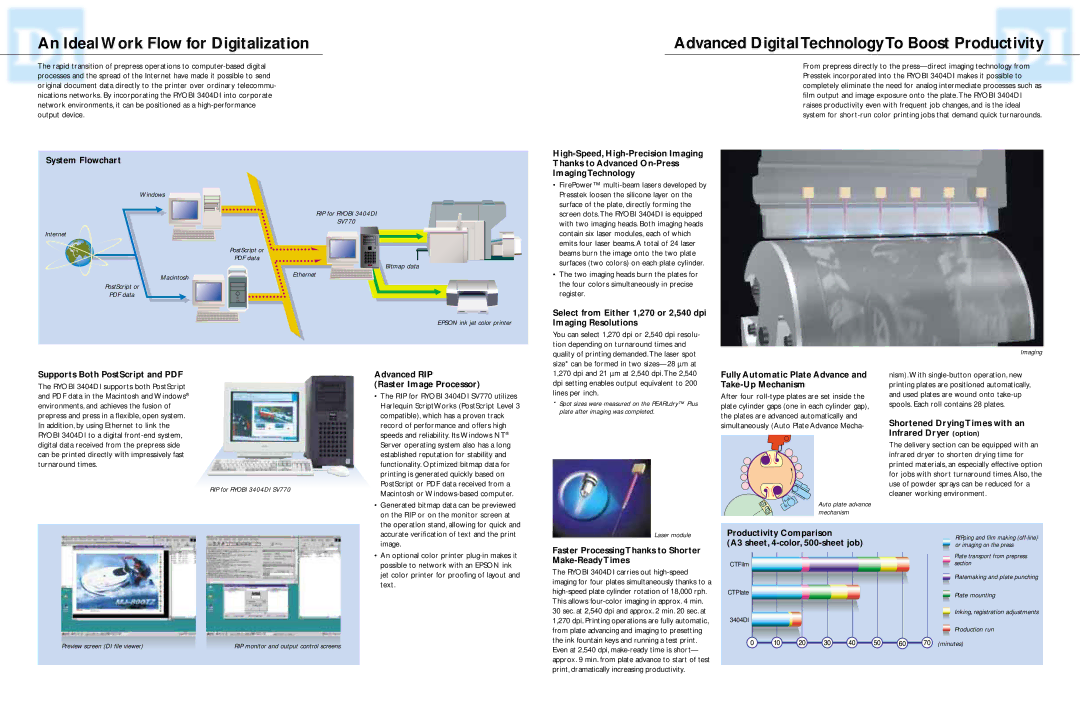

System Flowchart

Windows

Internet

Macintosh

PostScript or

PDF data

RIP for RYOBI 3404DI

SV770

PostScript or

PDF data

Bitmap data

Ethernet

EPSON ink jet color printer

•FirePower™

•The two imaging heads burn the plates for the four colors simultaneously in precise register.

Select from Either 1,270 or 2,540 dpi Imaging Resolutions

Supports Both PostScript and PDF

The RYOBI 3404DI supports both PostScript and PDF data in the Macintosh and Windows® environments, and achieves the fusion of prepress and press in a flexible, open system. In addition, by using Ethernet to link the RYOBI 3404DI to a digital

RIP for RYOBI 3404DI SV770

Preview screen (DI file viewer) | RIP monitor and output control screens |

|

|

Advanced RIP

(Raster Image Processor)

•The RIP for RYOBI 3404DI SV770 utilizes Harlequin ScriptWorks (PostScript Level 3 compatible), which has a proven track record of performance and offers high speeds and reliability. Its Windows NT® Server operating system also has a long established reputation for stability and functionality. Optimized bitmap data for printing is generated quickly based on PostScript or PDF data received from a Macintosh or

•Generated bitmap data can be previewed on the RIP or on the monitor screen at the operation stand, allowing for quick and accurate verification of text and the print image.

•An optional color printer

You can select 1,270 dpi or 2,540 dpi resolu- tion depending on turnaround times and quality of printing demanded.The laser spot size* can be formed in two

*Spot sizes were measured on the PEARLdry™ Plus plate after imaging was completed.

Laser module

Faster Processing Thanks to Shorter Make-Ready Times

The RYOBI 3404DI carries out

Fully Automatic Plate Advance and Take-Up Mechanism

After four

Auto plate advance mechanism

Productivity Comparison

(A3 sheet, 4-color, 500-sheet job)

CTFilm

CTPlate

3404DI

Imaging

nism).With

Shortened Drying Times with an Infrared Dryer (option)

The delivery section can be equipped with an infrared dryer to shorten drying time for printed materials, an especially effective option for jobs with short turnaround times.Also, the use of powder sprays can be reduced for a cleaner working environment.

RIPping and film making

Plate transport from prepress section

Platemaking and plate punching

Plate mounting

Inking, registration adjustments

Production run

(minutes)