MAINTENANCE AND REPAIR INSTRUCTIONS

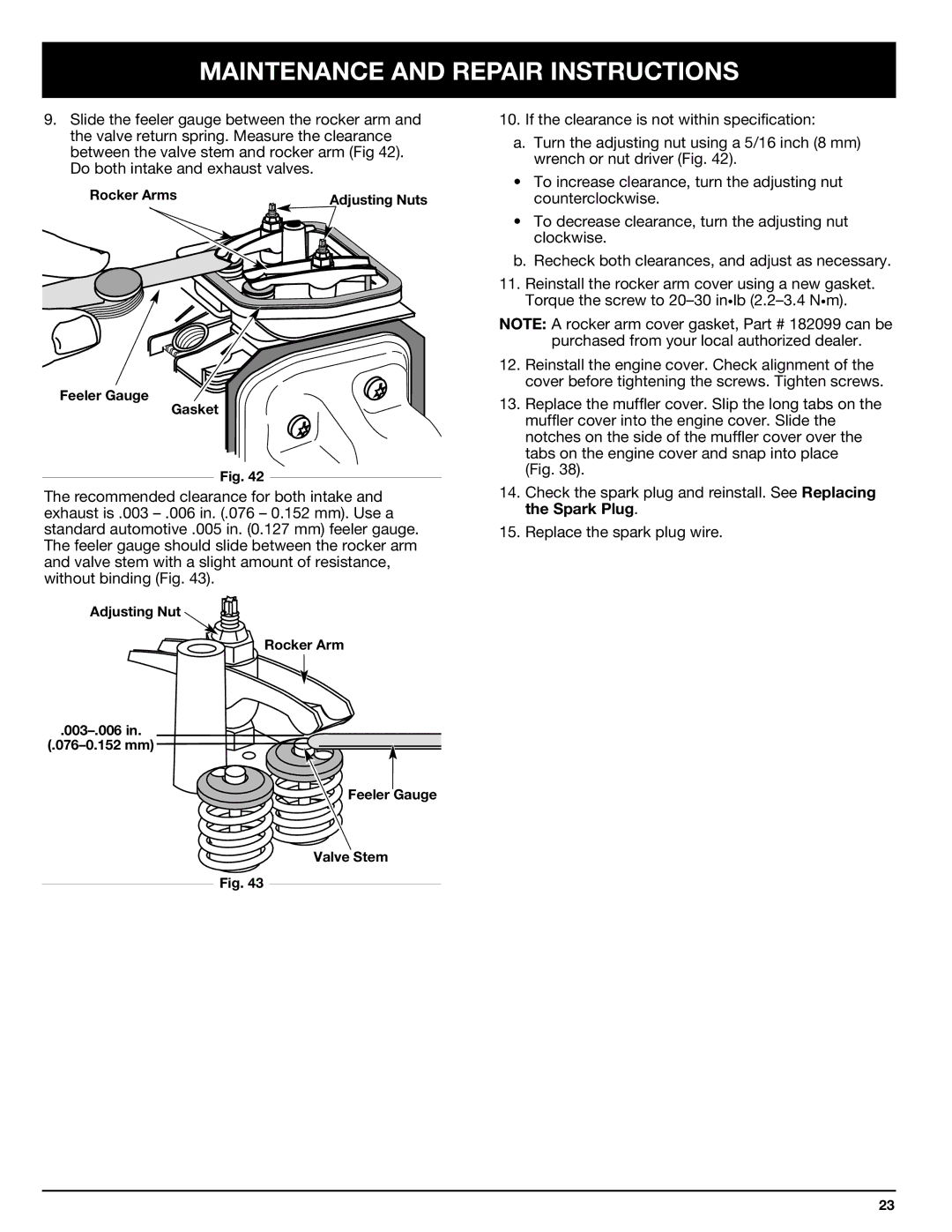

9.Slide the feeler gauge between the rocker arm and the valve return spring. Measure the clearance between the valve stem and rocker arm (Fig 42). Do both intake and exhaust valves.

Rocker Arms | Adjusting Nuts |

|

Feeler Gauge

Gasket

Fig. 42

The recommended clearance for both intake and exhaust is .003

Adjusting Nut

![]() Rocker Arm

Rocker Arm

![]() Feeler Gauge

Feeler Gauge

Valve Stem

Fig. 43

10.If the clearance is not within specification:

a.Turn the adjusting nut using a 5/16 inch (8 mm) wrench or nut driver (Fig. 42).

•To increase clearance, turn the adjusting nut counterclockwise.

•To decrease clearance, turn the adjusting nut clockwise.

b.Recheck both clearances, and adjust as necessary.

11.Reinstall the rocker arm cover using a new gasket. Torque the screw to

NOTE: A rocker arm cover gasket, Part # 182099 can be purchased from your local authorized dealer.

12.Reinstall the engine cover. Check alignment of the cover before tightening the screws. Tighten screws.

13.Replace the muffler cover. Slip the long tabs on the muffler cover into the engine cover. Slide the notches on the side of the muffler cover over the tabs on the engine cover and snap into place (Fig. 38).

14.Check the spark plug and reinstall. See Replacing the Spark Plug.

15.Replace the spark plug wire.

23