MAINTENANCE

WARNING:

When servicing, use only identical replacement parts. Use of any other parts may create a hazard or cause product damage.

WARNING:

Always wear safety goggles or safety glasses with side shields during power tool operation or when blowing dust. If operation is dusty, also wear a dust mask.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types of commercial solvents and may be damaged by their use. Use clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline, petroleum- based products, penetrating oils, etc., come in contact with plastic parts. Chemicals can damage, weaken or destroy plastic which may result in serious personal injury.

Electric tools used on fiberglass material, wallboard, spackling compounds, or plaster are subject to accelerated wear and possible premature failure because the fiberglass chips and grindings are highly abrasive to bearings, brushes, commu- tators, etc. Consequently, we do not recommend using this tool for extended work on these types of materials. However, if you do work with any of these materials, it is extremely important to clean the tool using compressed air.

LUBRICATION

All of the bearings in this product are lubricated with a sufficient amount of high grade lubricant for the life of the unit under normal operating conditions. Therefore, no further lubrication is required.

POWER SUPPLY CORD REPLACEMENT

If replacement of the power supply cord is necessary, this has to be done by an authorized service center in order to avoid a safety hazard.

WARNING:

To prevent accidental starting that could cause possible serious personal injury, turn off and unplug the tool before performing any maintenance or adjustment.

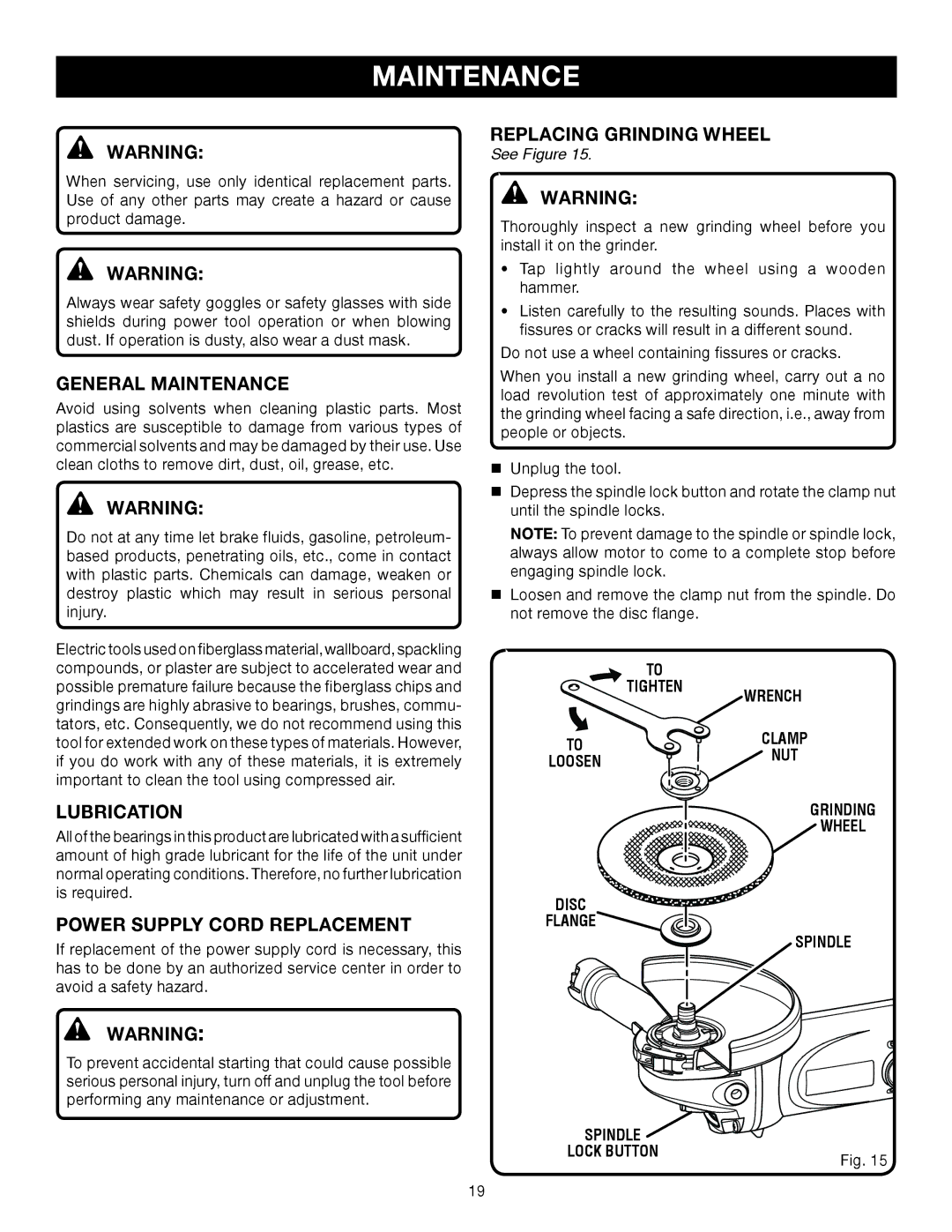

replacing GRINDING WHEEL

See Figure 15.

WARNING:

Thoroughly inspect a new grinding wheel before you install it on the grinder.

•Tap lightly around the wheel using a wooden

hammer .

•Listen carefully to the resulting sounds. Places with fissures or cracks will result in a different sound.

Do not use a wheel containing fissures or cracks.

When you install a new grinding wheel, carry out a no load revolution test of approximately one minute with the grinding wheel facing a safe direction, i.e., away from people or objects.

Unplug the tool.

Depress the spindle lock button and rotate the clamp nut until the spindle locks.

Note: To prevent damage to the spindle or spindle lock, always allow motor to come to a complete stop before engaging spindle lock.

Loosen and remove the clamp nut from the spindle. Do not remove the disc flange.

| to |

|

| tighten | Wrench |

|

| |

to |

| Clamp |

| nut | |

loosen |

| |

|

|

Grinding

![]() Wheel

Wheel

Disc

Flange![]()

Spindle

Spindle |

|

Lock Button | Fig. 15 |

|

19