ADJUSTMENT

NOTE: Remove gauge block before starting machine.

Thickness planing is the sizing of the material to a desired thickness, while creating a smooth surface parallel to the opposite side of the board.

The art of thickness planing consists mainly of using good judgement about the depth of cut in various situations. You must take into account:

1)The width of the timber

2)The hardness of the board

3)The dampness of the board

4)The straightness of the board

5)The grain direction

6)The grain structure

How these factors can effect the quality of the work can only be learned through experience. Whenever working with a new type of wood, or one with unusual problems, always make test cuts on scrap material prior to working on the actual piece.

FOR ADDITIONAL PLANING

If additional planing is needed to obtain the desired thickness or finish, hand crank the cutterhead no more than 3mm (at any one time) and complete another pass.

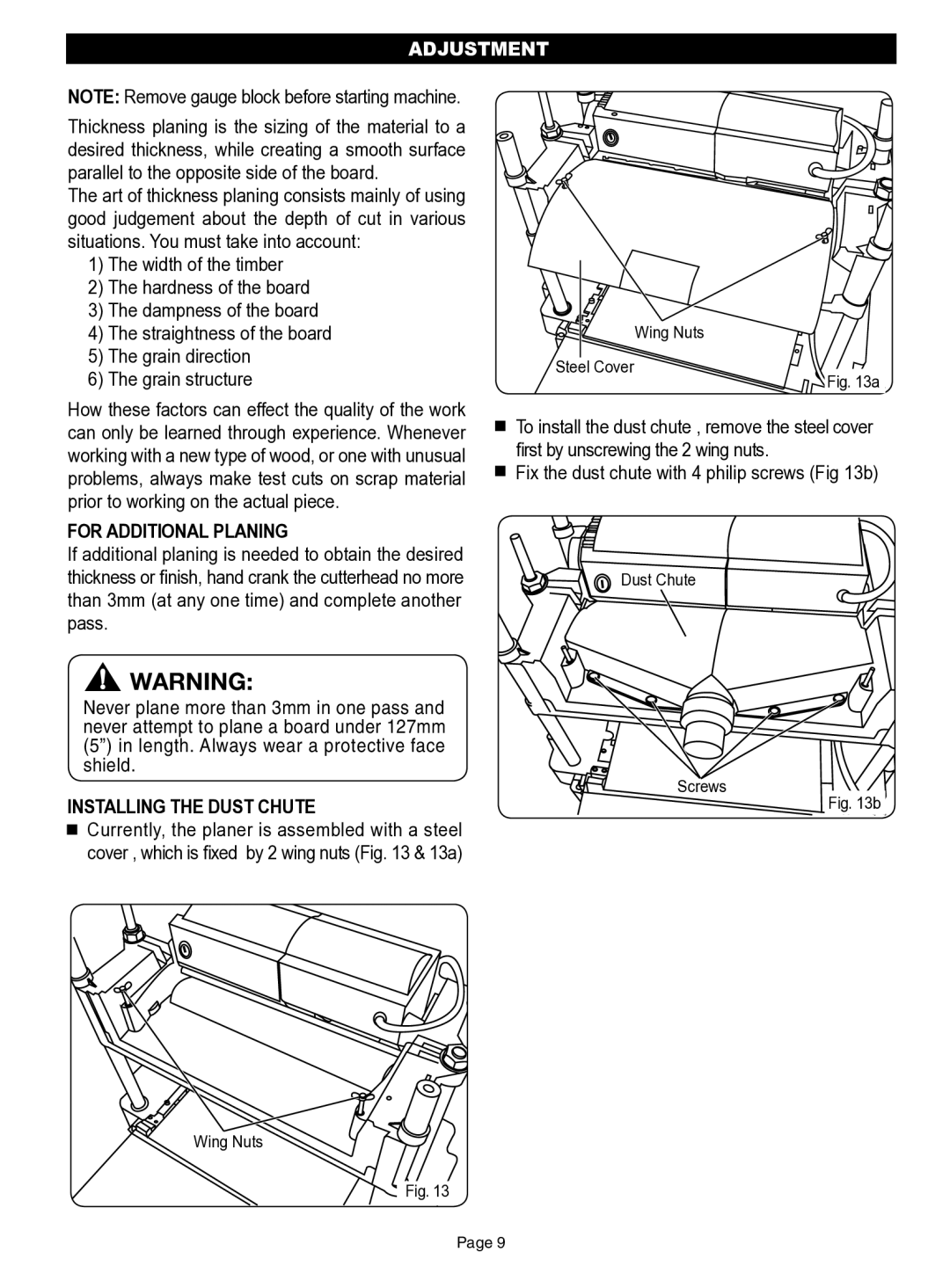

Wing Nuts

Steel Cover

Fig. 13a

![]() To install the dust chute , remove the steel cover first by unscrewing the 2 wing nuts.

To install the dust chute , remove the steel cover first by unscrewing the 2 wing nuts.

![]() Fix the dust chute with 4 philip screws (Fig 13b)

Fix the dust chute with 4 philip screws (Fig 13b)

Dust Chute

![]() WARNING:

WARNING:

Never plane more than 3mm in one pass and never attempt to plane a board under 127mm (5”) in length. Always wear a protective face shield.

Screws

INSTALLING THE DUST CHUTE

![]() Currently, the planer is assembled with a steel cover , which is fixed by 2 wing nuts (Fig. 13 & 13a)

Currently, the planer is assembled with a steel cover , which is fixed by 2 wing nuts (Fig. 13 & 13a)

Wing Nuts

Fig. 13

Fig. 13b

Page 9