BS903 specifications

The Ryobi BS903 is a versatile and efficient benchtop band saw that caters to both hobbyists and professionals looking for a reliable cutting tool. Known for its compact design and powerful features, the BS903 is an ideal choice for woodworking, metalworking, and various crafting projects.One of the standout characteristics of the Ryobi BS903 is its 9-inch throat capacity, which allows users to make deep cuts into a variety of materials. With a robust 2.5-amp motor, this band saw delivers a cutting speed of 2800 feet per minute, making it suitable for tackling intricate curves and straight cuts with ease. The bandsaw also features a table that measures 15-3/4 inches by 18 inches, providing ample workspace for larger projects.

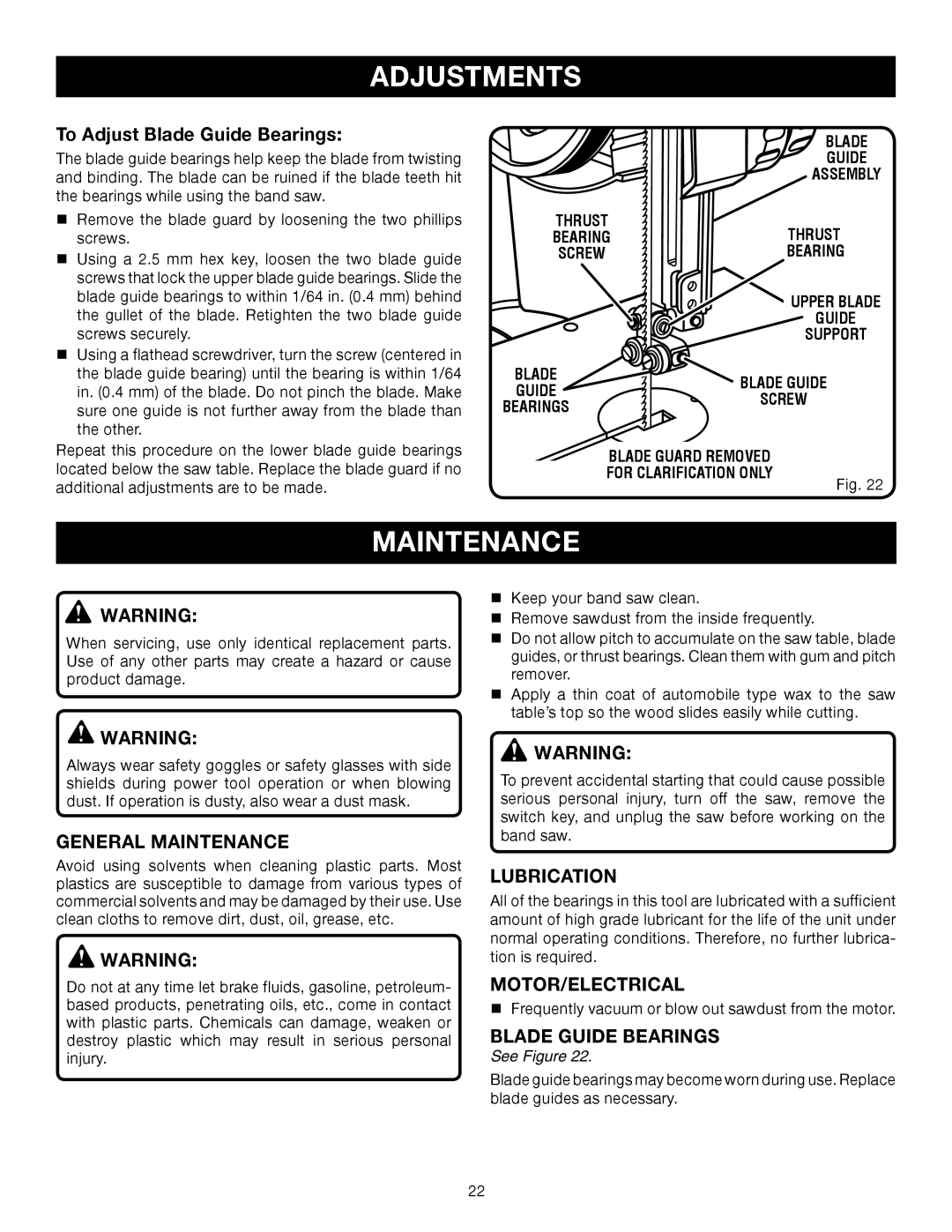

The BS903 incorporates a tilting table that can be adjusted from 0 to 45 degrees, allowing users to execute angled cuts with precision. This feature expands the versatility of the tool, enabling users to create beveled edges and complex designs effortlessly. Additionally, the built-in blade guide system ensures that the blade remains aligned during operation, enhancing accuracy and reducing the risk of deviation.

Another impressive feature of the Ryobi BS903 is its easy blade tracking adjustment, which simplifies the process of aligning the blade to the guide wheels. This user-friendly design promotes a seamless setup experience for both novice and experienced users. The band saw supports standard 1/4-inch blades, giving users the freedom to choose from a wide array of cutting options based on their specific needs.

Safety is a top priority in the design of the BS903. The band saw is equipped with a transparent blade guard and an integrated anti-kickback design, providing users with peace of mind while operating the tool. Additionally, the table is designed with a miter gauge slot, allowing for accurate crosscuts and better control.

Overall, the Ryobi BS903 band saw stands out in the market due to its combination of functionality, safety features, and ease of use. Whether you're a seasoned woodworker or just starting your crafting journey, the BS903 provides the reliability and performance required for a multitude of cutting tasks. With its thoughtful engineering, it's no surprise that the Ryobi BS903 continues to be a favored choice among DIY enthusiasts and professional tradespeople alike.