ROUTER MOUNTING (Cont'd)

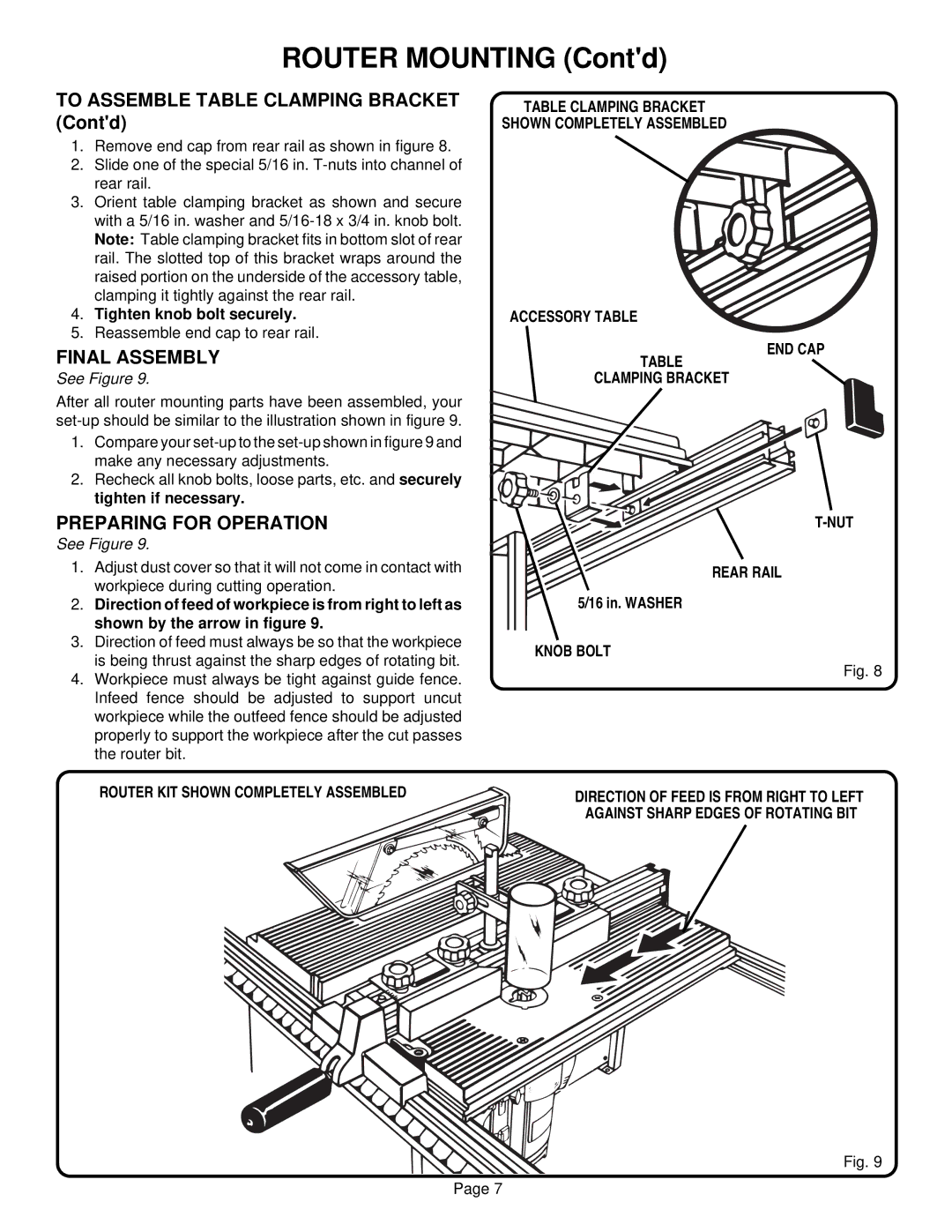

TO ASSEMBLE TABLE CLAMPING BRACKET (Cont'd)

1.Remove end cap from rear rail as shown in figure 8.

2.Slide one of the special 5/16 in.

3.Orient table clamping bracket as shown and secure with a 5/16 in. washer and

4.Tighten knob bolt securely.

5.Reassemble end cap to rear rail.

FINAL ASSEMBLY

See Figure 9.

After all router mounting parts have been assembled, your

1.Compare your

2.Recheck all knob bolts, loose parts, etc. and securely tighten if necessary.

PREPARING FOR OPERATION

See Figure 9.

1.Adjust dust cover so that it will not come in contact with workpiece during cutting operation.

2.Direction of feed of workpiece is from right to left as shown by the arrow in figure 9.

3.Direction of feed must always be so that the workpiece is being thrust against the sharp edges of rotating bit.

4.Workpiece must always be tight against guide fence. Infeed fence should be adjusted to support uncut workpiece while the outfeed fence should be adjusted properly to support the workpiece after the cut passes the router bit.

ROUTER KIT SHOWN COMPLETELY ASSEMBLED

TABLE CLAMPING BRACKET

SHOWN COMPLETELY ASSEMBLED

ACCESSORY TABLE

END CAP

TABLE

CLAMPING BRACKET

REAR RAIL

5/16 in. WASHER

KNOB BOLT

Fig. 8

DIRECTION OF FEED IS FROM RIGHT TO LEFT

AGAINST SHARP EDGES OF ROTATING BIT

Fig. 9

Page 7