OPERATION

TO BEVEL CUT

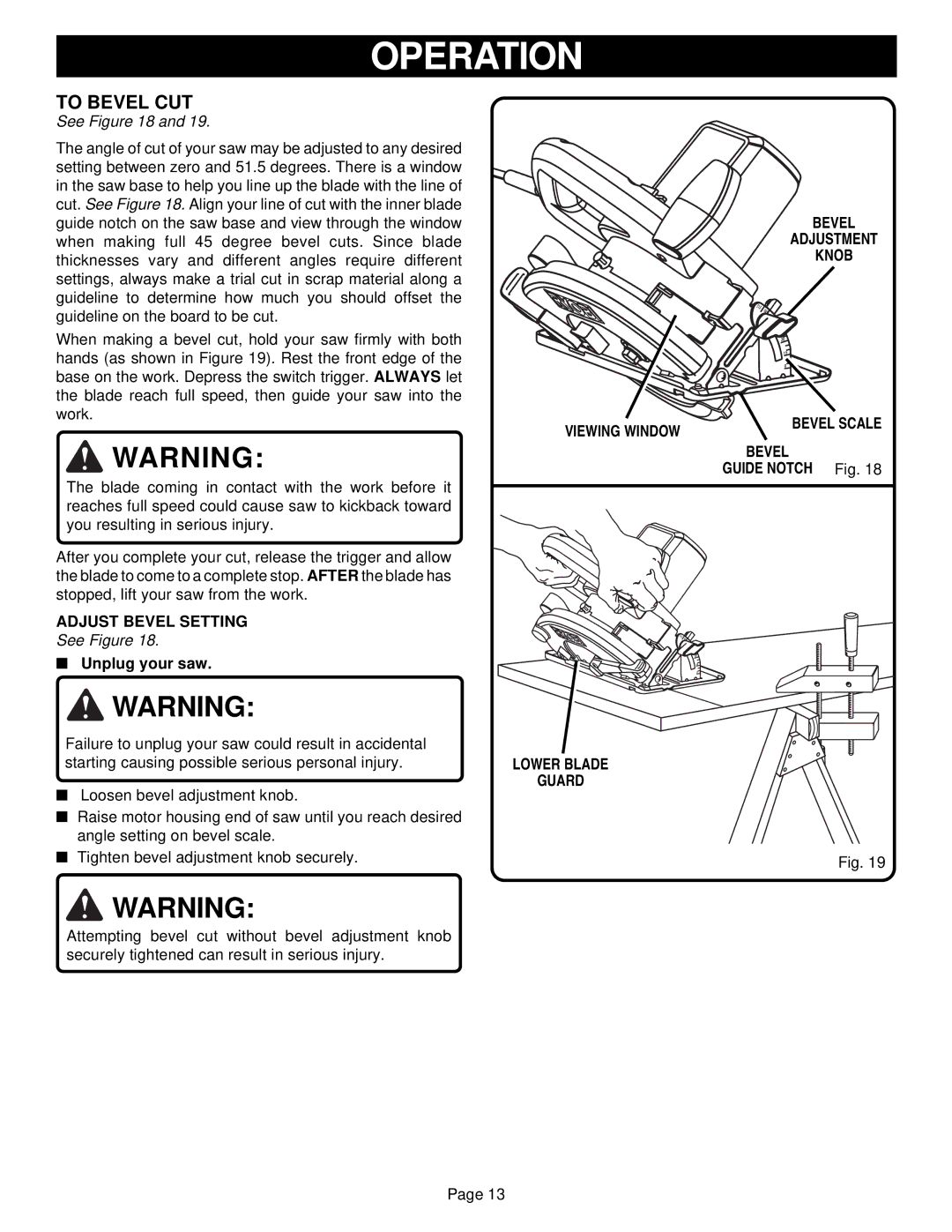

See Figure 18 and 19.

The angle of cut of your saw may be adjusted to any desired setting between zero and 51.5 degrees. There is a window in the saw base to help you line up the blade with the line of cut. See Figure 18. Align your line of cut with the inner blade guide notch on the saw base and view through the window when making full 45 degree bevel cuts. Since blade thicknesses vary and different angles require different settings, always make a trial cut in scrap material along a guideline to determine how much you should offset the guideline on the board to be cut.

When making a bevel cut, hold your saw firmly with both hands (as shown in Figure 19). Rest the front edge of the base on the work. Depress the switch trigger. ALWAYS let the blade reach full speed, then guide your saw into the work.

![]() WARNING:

WARNING:

The blade coming in contact with the work before it reaches full speed could cause saw to kickback toward you resulting in serious injury.

After you complete your cut, release the trigger and allow the blade to come to a complete stop. AFTER the blade has stopped, lift your saw from the work.

ADJUST BEVEL SETTING

See Figure 18.

■Unplug your saw.

![]() WARNING:

WARNING:

Failure to unplug your saw could result in accidental starting causing possible serious personal injury.

■Loosen bevel adjustment knob.

■Raise motor housing end of saw until you reach desired angle setting on bevel scale.

■Tighten bevel adjustment knob securely.

![]() WARNING:

WARNING:

Attempting bevel cut without bevel adjustment knob securely tightened can result in serious injury.

| BEVEL |

| ADJUSTMENT |

| KNOB |

| 51.5 |

| 45 |

| 30 |

| 15 |

| 0 |

VIEWING WINDOW | BEVEL SCALE |

| |

| BEVEL |

| GUIDE NOTCH Fig. 18 |

![]() 51.5

51.5

45![]()

30

15

0

LOWER BLADE

GUARD

Fig. 19

Page 13