OPERATION

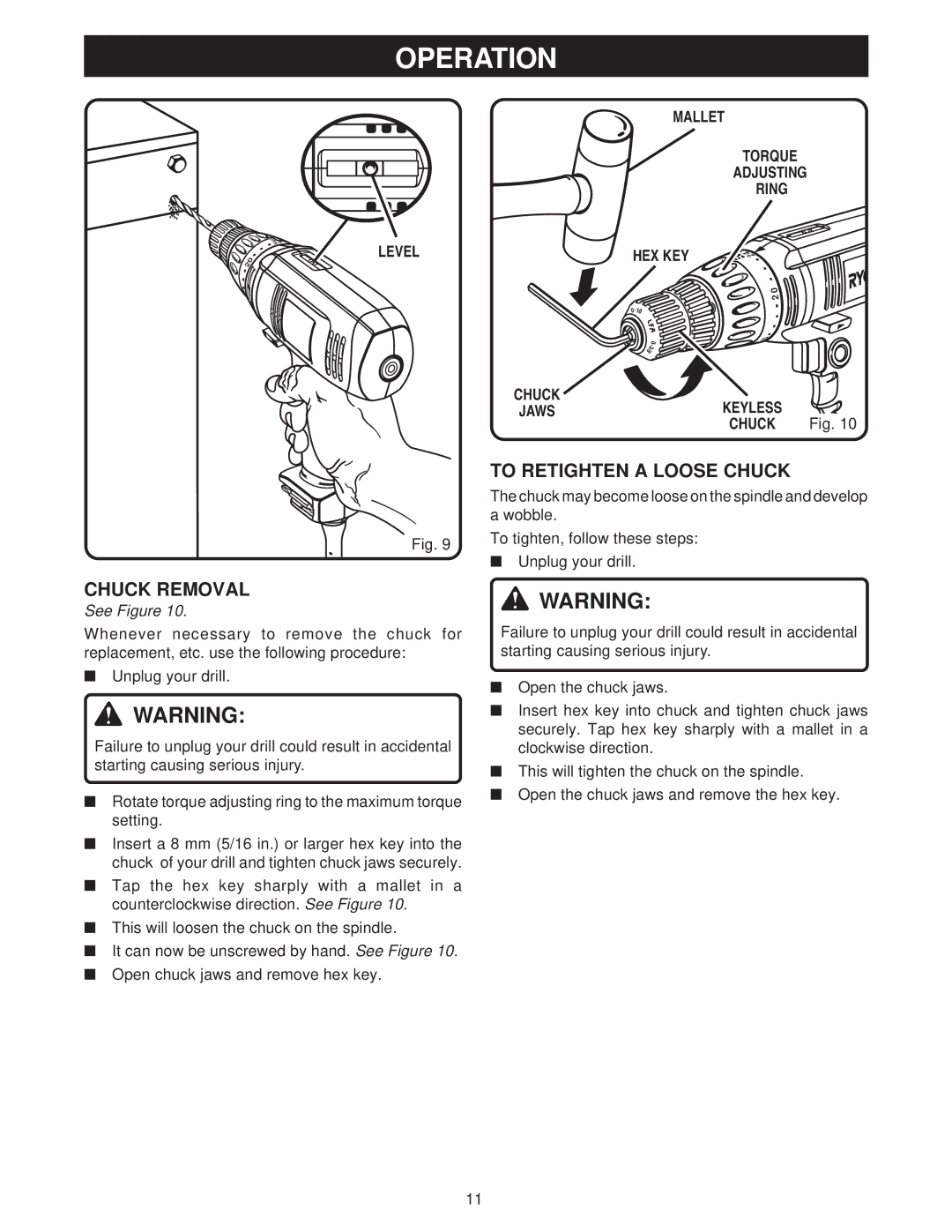

MALLET

TORQUE

ADJUSTING

RING

HEX KEY

L | |

F | |

A | |

| 0 |

| - |

8/ | 3 |

CHUCK

JAWS

![]() 24

24

0 2

5 ![]()

KEYLESS |

|

CHUCK | Fig. 10 |

24

LEVEL

20 ![]()

Fig. 9

CHUCK REMOVAL

See Figure 10.

Whenever necessary to remove the chuck for replacement, etc. use the following procedure:

■Unplug your drill.

WARNING:

Failure to unplug your drill could result in accidental starting causing serious injury.

■Rotate torque adjusting ring to the maximum torque setting.

■Insert a 8 mm (5/16 in.) or larger hex key into the chuck of your drill and tighten chuck jaws securely.

■Tap the hex key sharply with a mallet in a counterclockwise direction. See Figure 10.

■This will loosen the chuck on the spindle.

■It can now be unscrewed by hand. See Figure 10.

■Open chuck jaws and remove hex key.

TO RETIGHTEN A LOOSE CHUCK

The chuck may become loose on the spindle and develop a wobble.

To tighten, follow these steps:

■Unplug your drill.

WARNING:

Failure to unplug your drill could result in accidental starting causing serious injury.

■Open the chuck jaws.

■Insert hex key into chuck and tighten chuck jaws securely. Tap hex key sharply with a mallet in a clockwise direction.

■This will tighten the chuck on the spindle.

■Open the chuck jaws and remove the hex key.

11