FEATURES

PRODUCT SPECIFICATIONS:

| D45C |

Chuck Capacity | 1/16 in. to 3/8 in. |

| (1.6 mm to 10 mm) |

Rating | 120 V, 60 Hz, AC only |

Input | 4.5 Amperes |

Switch | Variable Speed |

No Load Speed | |

Clutch | 24 Positions |

APPLICATIONS

(Use only for the purpose listed below)

■Drilling in wood.

■Drilling in ceramics, plastics, fiberglass, and laminates.

■Drilling in both hard and soft metals.

■Using driving accessories, such as driving screws with screwdriver bits.

■Mixing paints.

WARNING:

If any parts are missing, do not operate your

OPERATION

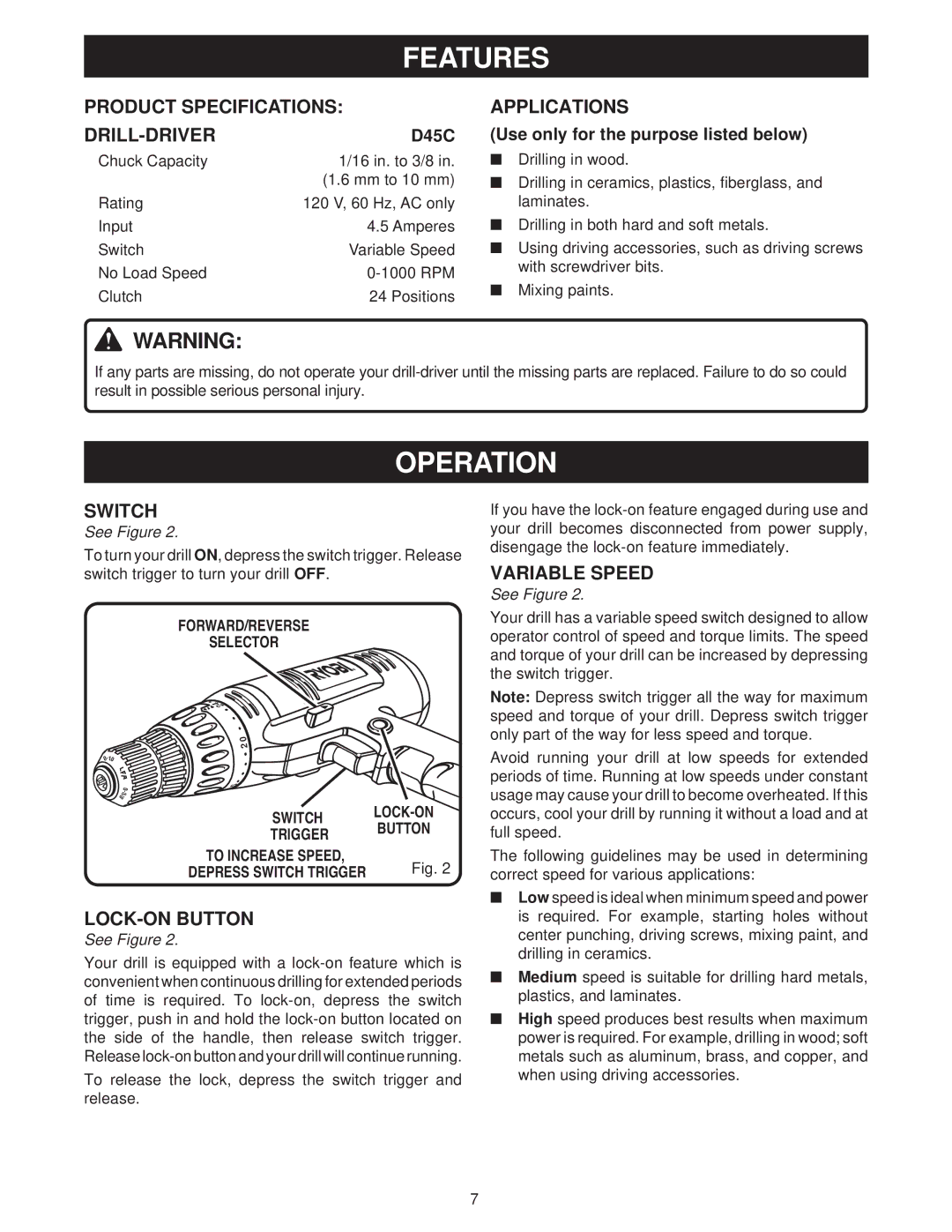

SWITCH

See Figure 2.

To turn your drill ON, depress the switch trigger. Release switch trigger to turn your drill OFF.

|

| FORWARD/REVERSE |

|

|

| SELECTOR |

|

|

| 24 |

|

|

| 0 |

|

|

| 2 |

|

|

|

| |

L |

|

| |

F |

|

| |

A |

|

| |

| 0 | 5 |

|

| - |

|

|

8/ | 3 |

|

|

|

| SWITCH | |

|

| BUTTON | |

|

| TRIGGER | |

|

|

| |

|

| TO INCREASE SPEED, | Fig. 2 |

|

| DEPRESS SWITCH TRIGGER | |

LOCK-ON BUTTON

See Figure 2.

Your drill is equipped with a

To release the lock, depress the switch trigger and release.

If you have the

VARIABLE SPEED

See Figure 2.

Your drill has a variable speed switch designed to allow operator control of speed and torque limits. The speed and torque of your drill can be increased by depressing the switch trigger.

Note: Depress switch trigger all the way for maximum speed and torque of your drill. Depress switch trigger only part of the way for less speed and torque.

Avoid running your drill at low speeds for extended periods of time. Running at low speeds under constant usage may cause your drill to become overheated. If this occurs, cool your drill by running it without a load and at full speed.

The following guidelines may be used in determining correct speed for various applications:

■Low speed is ideal when minimum speed and power is required. For example, starting holes without center punching, driving screws, mixing paint, and drilling in ceramics.

■Medium speed is suitable for drilling hard metals, plastics, and laminates.

■High speed produces best results when maximum power is required. For example, drilling in wood; soft metals such as aluminum, brass, and copper, and when using driving accessories.

7