OPERATION

SCREWDRIVING

TORQUE ADJUSTMENT

(Driving power of your drill-driver)

When using your

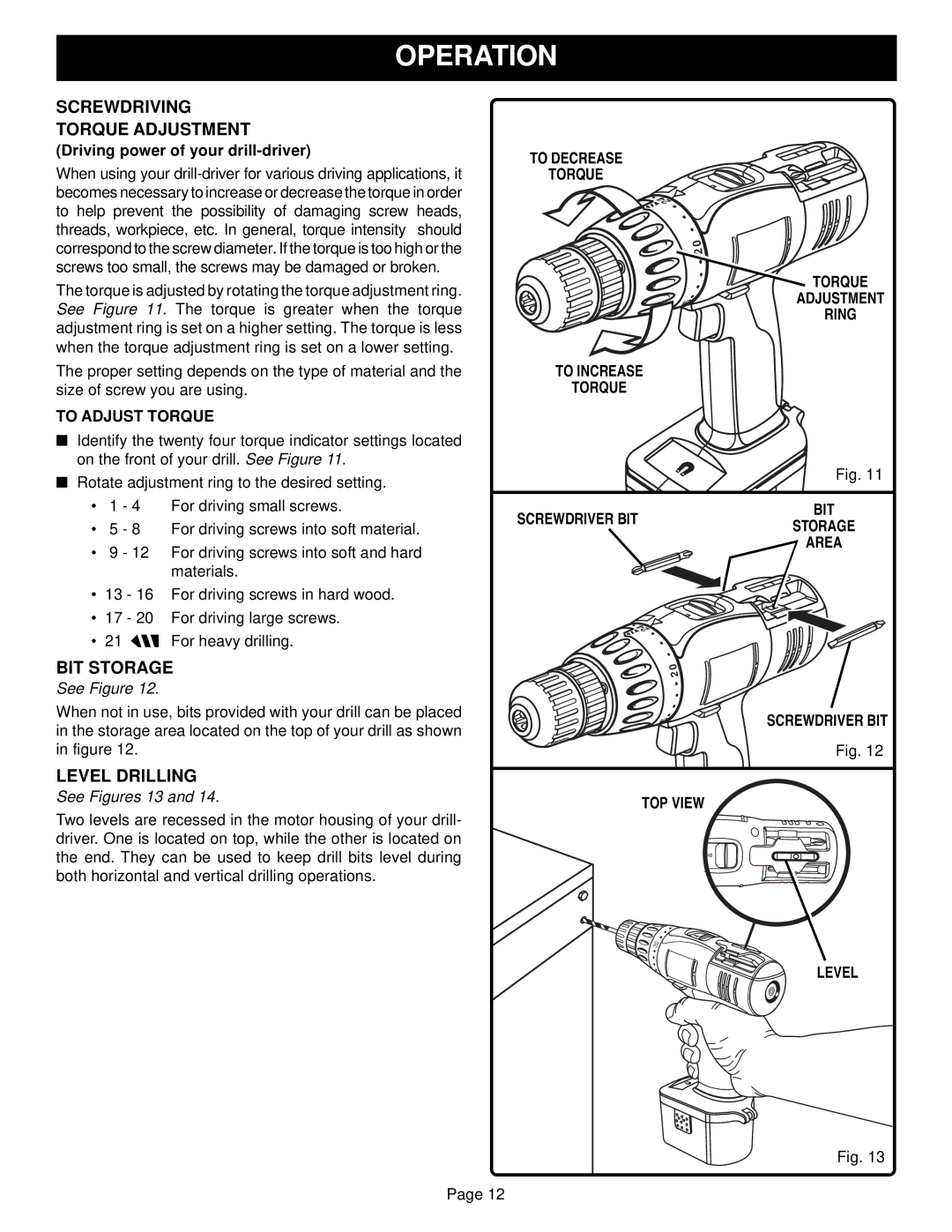

The torque is adjusted by rotating the torque adjustment ring. See Figure 11. The torque is greater when the torque adjustment ring is set on a higher setting. The torque is less when the torque adjustment ring is set on a lower setting.

The proper setting depends on the type of material and the size of screw you are using.

TO ADJUST TORQUE

■Identify the twenty four torque indicator settings located on the front of your drill. See Figure 11.

■Rotate adjustment ring to the desired setting.

•1 - 4 For driving small screws.

•5 - 8 For driving screws into soft material.

•9 - 12 For driving screws into soft and hard materials.

•13 - 16 For driving screws in hard wood.

•17 - 20 For driving large screws.

• 21 ![]() For heavy drilling.

For heavy drilling.

BIT STORAGE

See Figure 12.

When not in use, bits provided with your drill can be placed in the storage area located on the top of your drill as shown in figure 12.

TO DECREASE

TORQUE

![]() 24

24

0 2

5![]()

TO INCREASE

TORQUE

SCREWDRIVER BIT

![]() 24

24

0 2

5![]()

TORQUE

ADJUSTMENT

RING

Fig. 11

BIT

STORAGE

![]() AREA

AREA

SCREWDRIVER BIT

Fig. 12

LEVEL DRILLING

See Figures 13 and 14. | TOP VIEW |

|

Two levels are recessed in the motor housing of your drill- driver. One is located on top, while the other is located on the end. They can be used to keep drill bits level during both horizontal and vertical drilling operations.

20

Page 12

LEVEL

Fig. 13