UNPACKING

■Carefully remove the sander, and accessories from box. Make sure all items listed in the Packing List are included.

■Do not discard the packing material until you have carefully inspected and satisfactorily operated sander.

■Examine all parts and accessories to make sure that no breakage has occurred during shipping. Any damaged part should be replaced before attempting to use the tool.

PACKING LIST

Sanding Disc (quantity 3)

Conversion Pad (for velcro type sanding discs)

Dust Bag Assembly

Warranty Card

Operator's Manual

OPERATION

The backing pad on your sander provides the capability to use sanding discs with pressure sensitive adhesive back- ing material. You also receive a conversion pad which al- lows use of sanding discs with velcro type backing material.

![]() WARNING:

WARNING:

Your sander should never be connected to power supply when you are assembling parts, making adjustments, assembling or replacing sanding disc, cleaning, or when not in use. Disconnecting your sander will prevent accidental starting that could cause serious personal injury.

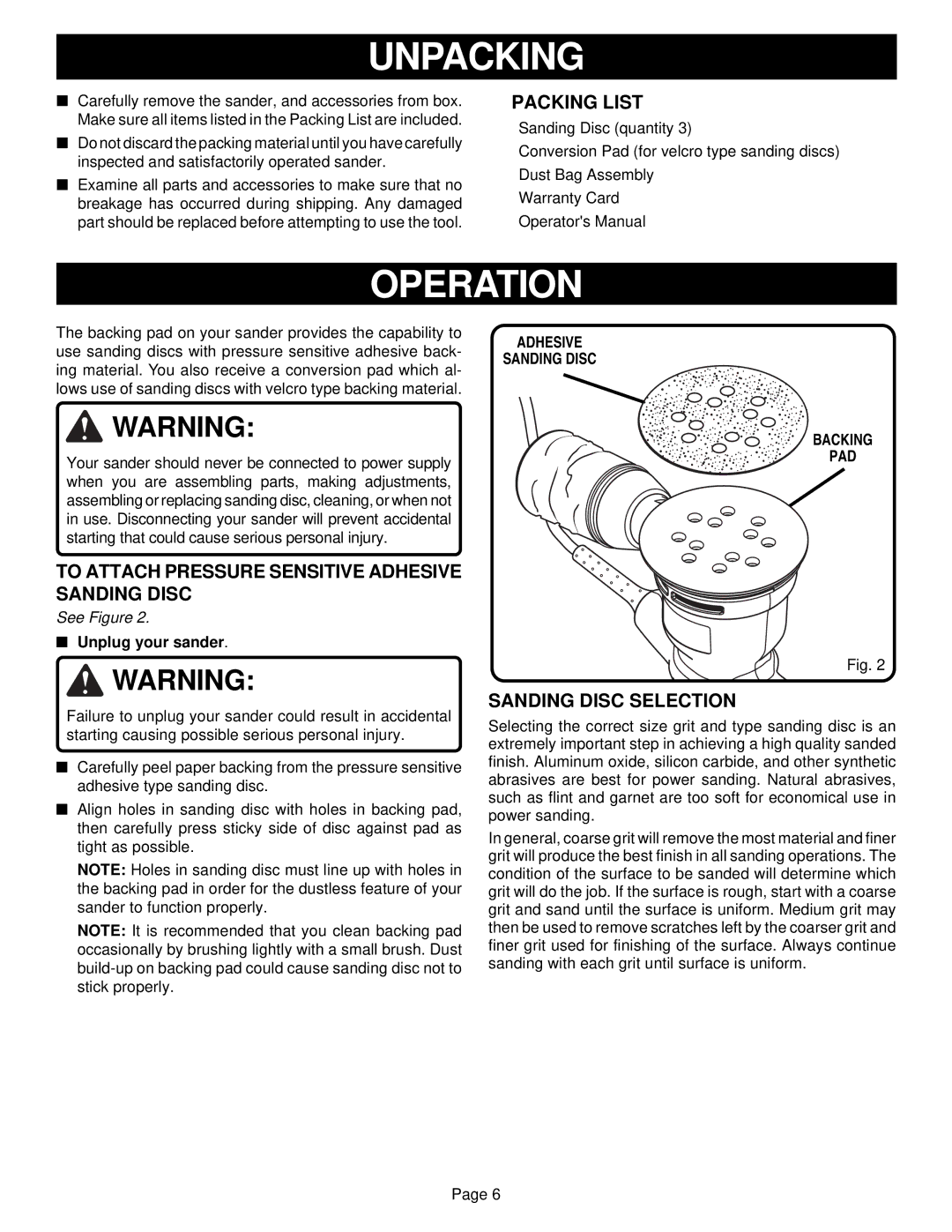

TO ATTACH PRESSURE SENSITIVE ADHESIVE SANDING DISC

See Figure 2.

■Unplug your sander.

![]() WARNING:

WARNING:

Failure to unplug your sander could result in accidental starting causing possible serious personal injury.

■Carefully peel paper backing from the pressure sensitive adhesive type sanding disc.

■Align holes in sanding disc with holes in backing pad, then carefully press sticky side of disc against pad as tight as possible.

NOTE: Holes in sanding disc must line up with holes in the backing pad in order for the dustless feature of your sander to function properly.

NOTE: It is recommended that you clean backing pad occasionally by brushing lightly with a small brush. Dust

ADHESIVE

SANDING DISC

BACKING

PAD

Fig. 2

SANDING DISC SELECTION

Selecting the correct size grit and type sanding disc is an extremely important step in achieving a high quality sanded finish. Aluminum oxide, silicon carbide, and other synthetic abrasives are best for power sanding. Natural abrasives, such as flint and garnet are too soft for economical use in power sanding.

In general, coarse grit will remove the most material and finer grit will produce the best finish in all sanding operations. The condition of the surface to be sanded will determine which grit will do the job. If the surface is rough, start with a coarse grit and sand until the surface is uniform. Medium grit may then be used to remove scratches left by the coarser grit and finer grit used for finishing of the surface. Always continue sanding with each grit until surface is uniform.

Page 6