MAINTENANCE

NOTE: New chain tends to stretch; check chain tension frequently and tension as required.

CAUTION:

Chain tensioned while warm, can be too tight upon cooling. Check the “cold tension” before next use.

REPLACING THE BAR AND CHAIN

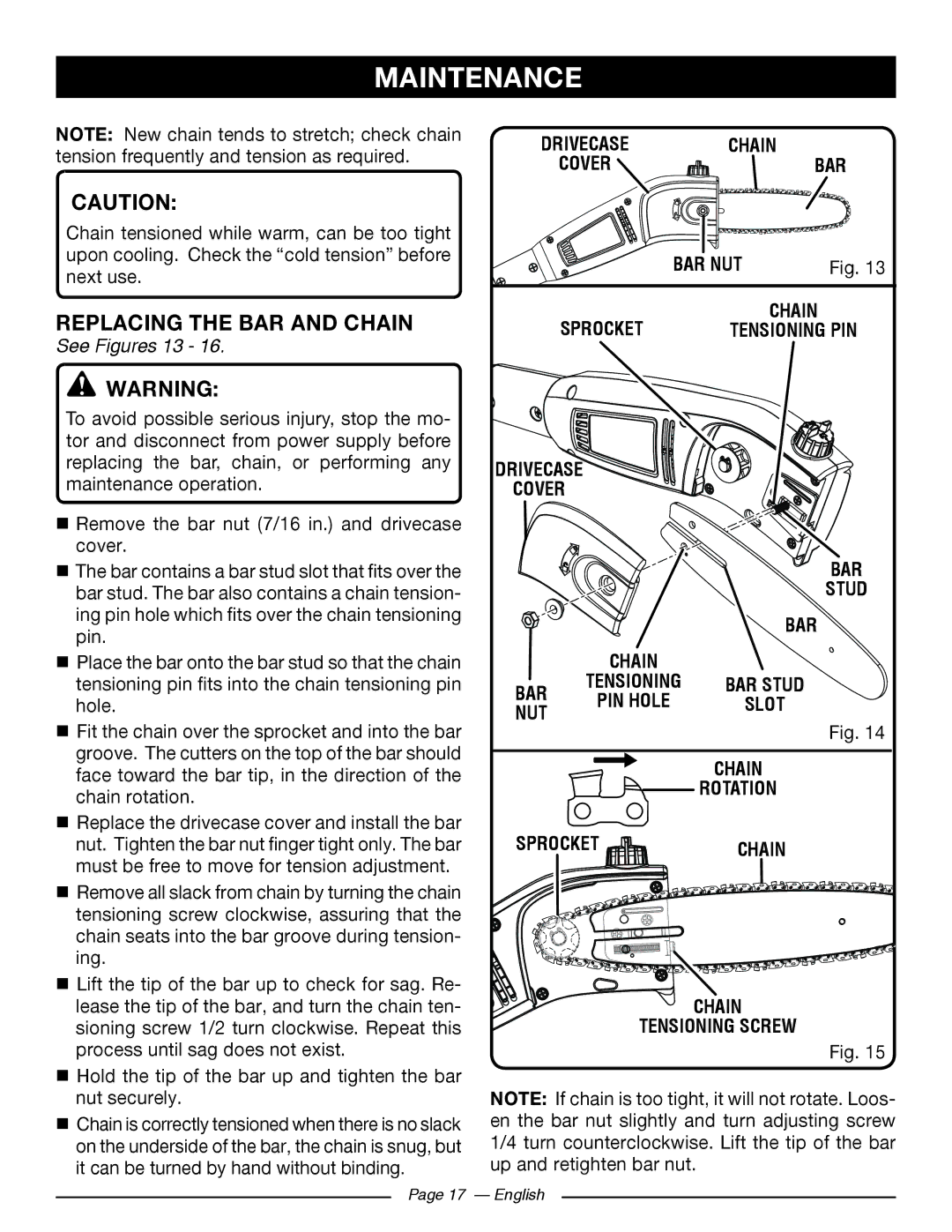

See Figures 13 - 16.

![]() WARNING:

WARNING:

To avoid possible serious injury, stop the mo- tor and disconnect from power supply before replacing the bar, chain, or performing any maintenance operation.

nRemove the bar nut (7/16 in.) and drivecase cover.

nThe bar contains a bar stud slot that fits over the bar stud. The bar also contains a chain tension- ing pin hole which fits over the chain tensioning pin.

nPlace the bar onto the bar stud so that the chain tensioning pin fits into the chain tensioning pin hole.

nFit the chain over the sprocket and into the bar groove. The cutters on the top of the bar should face toward the bar tip, in the direction of the chain rotation.

nReplace the drivecase cover and install the bar nut. Tighten the bar nut finger tight only. The bar must be free to move for tension adjustment.

nRemove all slack from chain by turning the chain tensioning screw clockwise, assuring that the chain seats into the bar groove during tension- ing.

nLift the tip of the bar up to check for sag. Re- lease the tip of the bar, and turn the chain ten- sioning screw 1/2 turn clockwise. Repeat this process until sag does not exist.

nHold the tip of the bar up and tighten the bar nut securely.

nChain is correctly tensioned when there is no slack on the underside of the bar, the chain is snug, but it can be turned by hand without binding.

DRIVECASE | CHAIN | |

COVER |

| BAR |

| BAR NUT | Fig. 13 |

SPROCKET |

| CHAIN |

TENSIONING PIN | ||

DRIVECASE ![]()

![]()

![]()

![]()

![]()

COVER

|

| BAR | |

|

| STUD | |

|

| BAR | |

| CHAIN |

| |

BAR | TENSIONING | BAR STUD | |

PIN HOLE | SLOT | ||

NUT | |||

|

|

Fig. 14

| CHAIN |

| ROTATION |

SPROCKET | CHAIN |

|

![]()

![]()

![]()

![]()

![]()

![]()

![]() CHAIN TENSIONING SCREW

CHAIN TENSIONING SCREW

Fig. 15

NOTE: If chain is too tight, it will not rotate. Loos- en the bar nut slightly and turn adjusting screw 1/4 turn counterclockwise. Lift the tip of the bar up and retighten bar nut.

Page 17 — English