Howto connectyour extended power cables

※Items to prepare

(compressor and insulation tape should be prepared by an installation technician.)

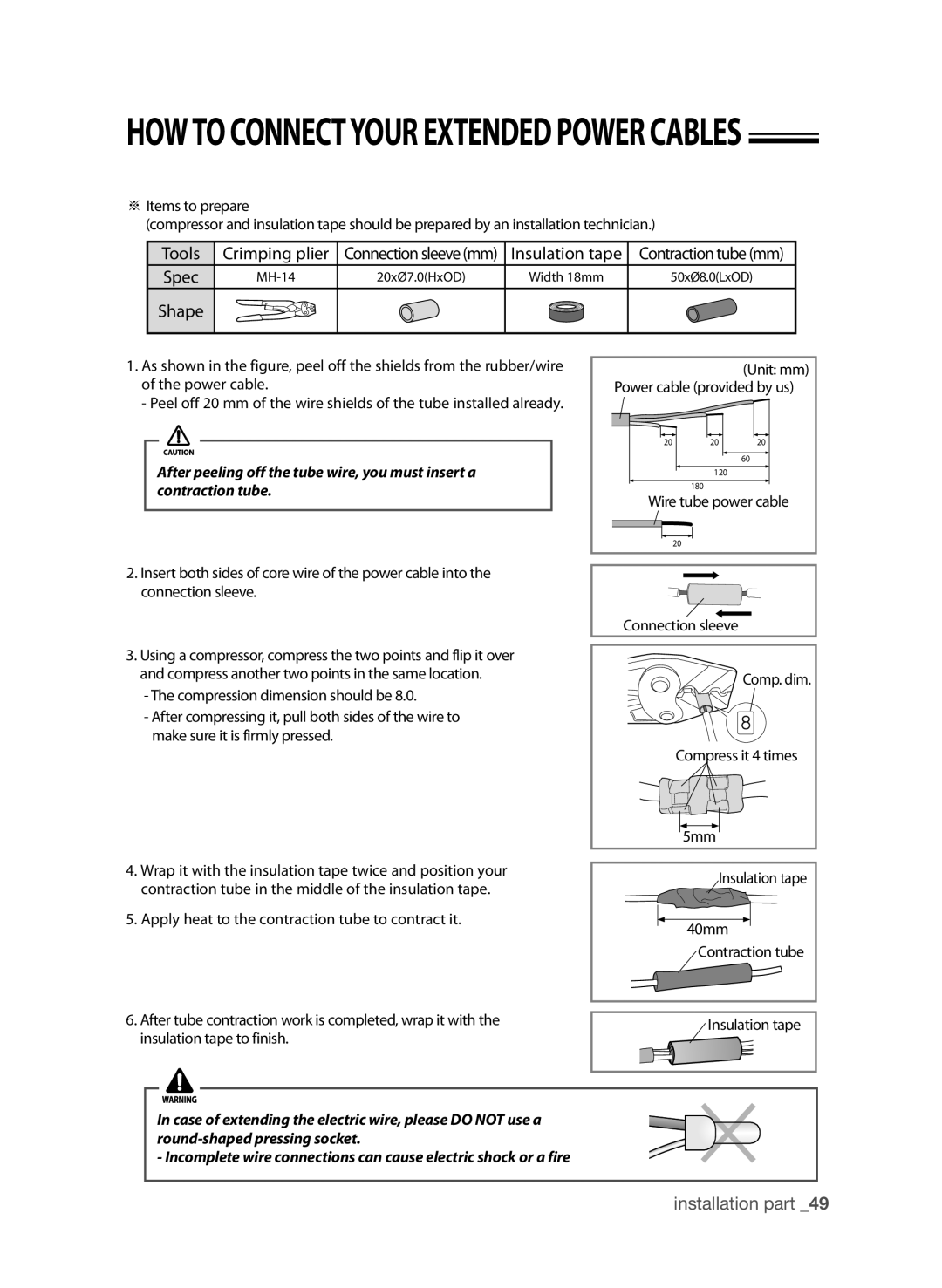

Tools | Crimping plier | Connection sleeve (mm) | Insulation tape | Contraction tube (mm) |

Spec | 20xØ7.0(HxOD) | Width 18mm | 50xØ8.0(LxOD) | |

Shape |

|

|

|

|

1.As shown in the figure, peel off the shields from the rubber/wire of the power cable.

- Peel off 20 mm of the wire shields of the tube installed already.

After peeling off the tube wire, you must insert a contraction tube.

2.Insert both sides of core wire of the power cable into the connection sleeve.

3.Using a compressor, compress the two points and flip it over and compress another two points in the same location.

-The compression dimension should be 8.0.

-After compressing it, pull both sides of the wire to make sure it is firmly pressed.

(Unit: mm)

Power cable (provided by us)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

| 20 |

| 20 |

![]() 60 120

60 120

180

Wire tube power cable

20

Connection sleeve

Comp. dim.

Compress it 4 times

5mm

4.Wrap it with the insulation tape twice and position your contraction tube in the middle of the insulation tape.

5.Apply heat to the contraction tube to contract it.

6.After tube contraction work is completed, wrap it with the insulation tape to finish.

Insulation tape

40mm ![]() Contraction tube

Contraction tube

Insulation tape

In case of extending the electric wire, please DO NOT use a

- Incomplete wire connections can cause electric shock or a fire