M-10e specifications

The SATO M-10e is a state-of-the-art label printer designed specifically for industries that require reliable, high-quality printing solutions. This robust printer incorporates advanced technologies, making it ideal for labels in various sectors, including healthcare, logistics, retail, and manufacturing.One of the standout features of the SATO M-10e is its exceptional print resolution. With a maximum resolution of 600 dpi, it ensures crisp, clear, and detailed labels that are essential for barcodes, logos, and intricate designs. This level of resolution not only enhances the readability of printed information but also reinforces branding through high-quality visuals.

The M-10e employs the latest Thermal Transfer printing technology, which allows for a wider range of media compatibility. Users can print on various substrates, including paper, synthetic materials, and specialty media. This versatility makes the M-10e suitable for different applications, from product labeling to shipping tags.

In terms of speed, the SATO M-10e performs admirably, capable of printing up to 8 inches per second. This high printing speed is crucial for environments with demanding operational timelines, ensuring efficiency without compromising quality. The printer's fast processing capabilities are supported by its powerful onboard processor, allowing for quick data handling and print jobs.

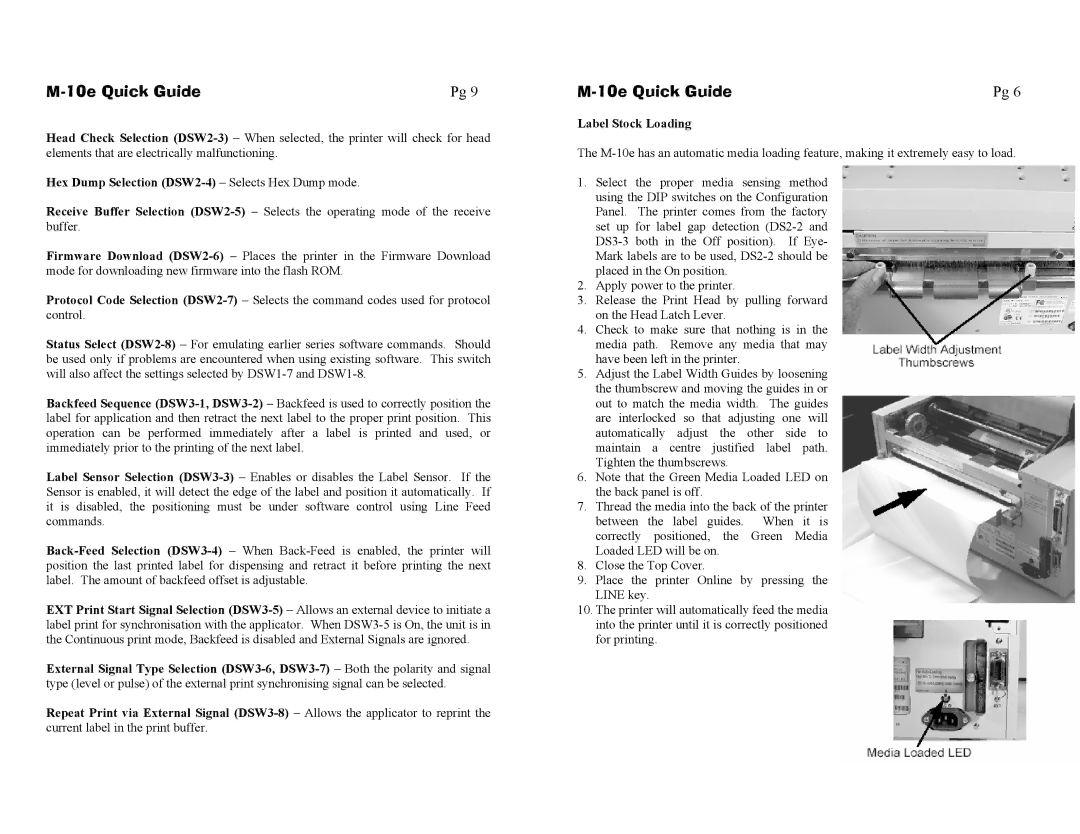

Another key characteristic of the M-10e is its user-friendly interface. The printer is equipped with an intuitive LCD display that simplifies navigation through its various settings and features. Additionally, the M-10e is designed for easy media loading, minimizing downtime and allowing users to switch between different label formats with ease.

Connectivity options are also robust, with the M-10e featuring USB, Serial, and Ethernet ports. This ensures seamless integration into existing IT infrastructure, whether standalone or networked environments. Moreover, the printer is compatible with various programming languages, making it straightforward to deploy in diverse applications.

The SATO M-10e is engineered with durability in mind. Built to withstand the rigors of industrial environments, it offers a solid construction that ensures longevity and reliability. With its combination of high performance, ease of use, and adaptability, the SATO M-10e stands out as a premier choice for businesses seeking an effective labeling solution to meet their operational needs.