R

Section 7

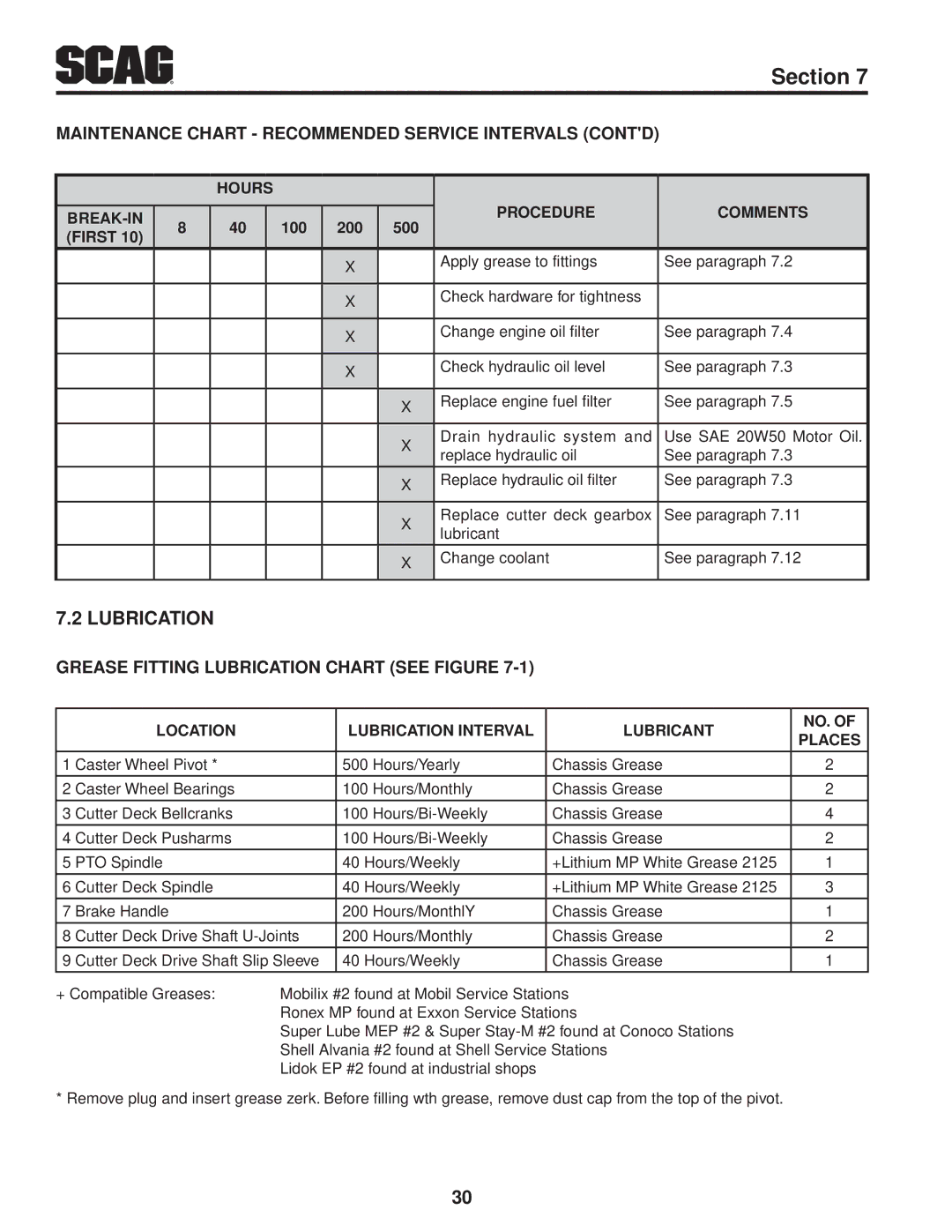

MAINTENANCE CHART - RECOMMENDED SERVICE INTERVALS (CONT'D)

|

| HOURS |

|

|

|

|

| |

|

|

|

|

|

| Procedure | Comments | |

8 | 40 | 100 | 200 | 500 | ||||

|

| |||||||

(First 10) |

|

| ||||||

|

|

|

|

|

|

| ||

|

|

|

| X |

| Apply grease to fittings | See paragraph 7.2 | |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| |

|

|

|

| X |

| Check hardware for tightness |

| |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| |

|

|

|

| X |

| Change engine oil filter | See paragraph 7.4 | |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| |

|

|

|

| X |

| Check hydraulic oil level | See paragraph 7.3 | |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| |

|

|

|

|

| X | Replace engine fuel filter | See paragraph 7.5 | |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| |

|

|

|

|

| X | Drain hydraulic system and | Use SAE 20W50 Motor Oil. | |

|

|

|

|

| replace hydraulic oil | See paragraph 7.3 | ||

|

|

|

|

|

| |||

|

|

|

|

| X | Replace hydraulic oil filter | See paragraph 7.3 | |

|

|

|

|

|

|

|

XReplace cutter deck gearbox See paragraph 7.11 lubricant

X | Change coolant | See paragraph 7.12 |

|

|

7.2 Lubrication

GREASE FITTING LUBRICATION CHART (SEE FIGURE 7-1)

| LOCATION | LUBRICATION INTERVAL | LUBRICANT | NO. OF | |

| PLACES | ||||

|

|

|

|

| |

1 | Caster Wheel Pivot * | 500 | Hours/Yearly | Chassis Grease | 2 |

2 | Caster Wheel Bearings | 100 | Hours/Monthly | Chassis Grease | 2 |

3 | Cutter Deck Bellcranks | 100 | Chassis Grease | 4 | |

4 | Cutter Deck Pusharms | 100 | Chassis Grease | 2 | |

5 | PTO Spindle | 40 Hours/Weekly | +Lithium MP White Grease 2125 | 1 | |

6 | Cutter Deck Spindle | 40 Hours/Weekly | +Lithium MP White Grease 2125 | 3 | |

7 | Brake Handle | 200 | Hours/MonthlY | Chassis Grease | 1 |

8 | Cutter Deck Drive Shaft | 200 | Hours/Monthly | Chassis Grease | 2 |

9 | Cutter Deck Drive Shaft Slip Sleeve | 40 Hours/Weekly | Chassis Grease | 1 | |

+ Compatible Greases: | Mobilix #2 found at Mobil Service Stations |

| Ronex MP found at Exxon Service Stations |

| Super Lube MEP #2 & Super |

| Shell Alvania #2 found at Shell Service Stations |

| Lidok EP #2 found at industrial shops |

* Remove plug and insert grease zerk. Before filling wth grease, remove dust cap from the top of the pivot.

30