STT61V-25CH-LP, STT52V-25CH-LP specifications

Scag Power Equipment has long been synonymous with durability and performance in the lawn care industry, and their STT52V-25CH-LP and STT61V-25CH-LP mowers exemplify this commitment. Both models are part of the Scag Turf Tiger II series, designed for commercial landscapers and serious homeowners who demand the best in cutting efficiency and reliability.The STT52V-25CH-LP features a 52-inch cutting deck, while the STT61V-25CH-LP boasts a 61-inch deck, allowing users to choose according to the size of their lawn or landscape maintenance requirements. The decks are constructed from high-strength steel, ensuring longer life and resistance to wear from heavy use. The signature Velocity Plus deck design enhances airflow for superior cutting quality, resulting in cleaner cuts and better grass dispersal.

Powered by a robust 25 HP Kohler Command Pro engine, both models deliver the necessary power to tackle tough mowing jobs with ease. The engine's exceptional torque and performance ensure that even thick grass doesn't slow these machines down. Additionally, the Kohler engine is designed for improved fuel efficiency, helping operators save on fuel costs during long hours of operation.

One of the standout features of the STT52V-25CH-LP and STT61V-25CH-LP is their advanced hydrostatic transmission, providing smooth and responsive speed control. Operators can effortlessly adjust their speed and direction, making it easy to navigate tight spaces and uneven terrain. The ergonomic operator platform enhances comfort, with padded seats and adjustable armrests allowing for extended periods of mowing without fatigue.

Both models come equipped with a heavy-duty, commercial-grade transmission, capable of withstanding the rigors of daily use in demanding conditions. Additionally, they feature an intuitive control panel, allowing users to easily monitor important metrics, such as fuel levels and hour meters.

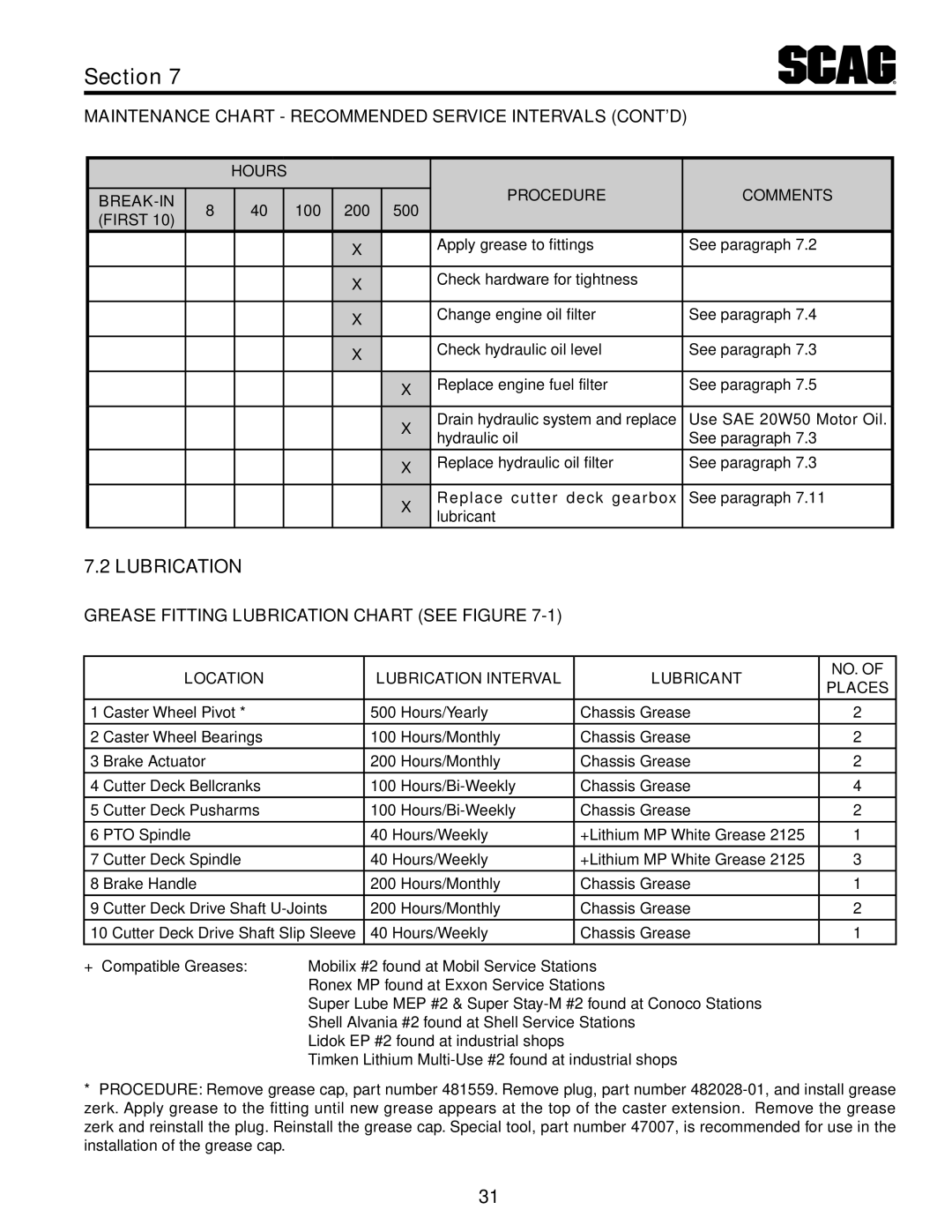

For added convenience, these mowers incorporate an easy-access maintenance design, allowing for quick inspections and routine servicing. With a focus on user-friendliness, Scag has ensured that operators can maintain their equipment with minimal downtime.

In summary, the STT52V-25CH-LP and STT61V-25CH-LP from Scag Power Equipment offer a compelling combination of power, performance, and user-friendly features. Ideal for commercial landscapers and serious gardening enthusiasts alike, these mowers stand ready to deliver exceptional results in any mowing environment.