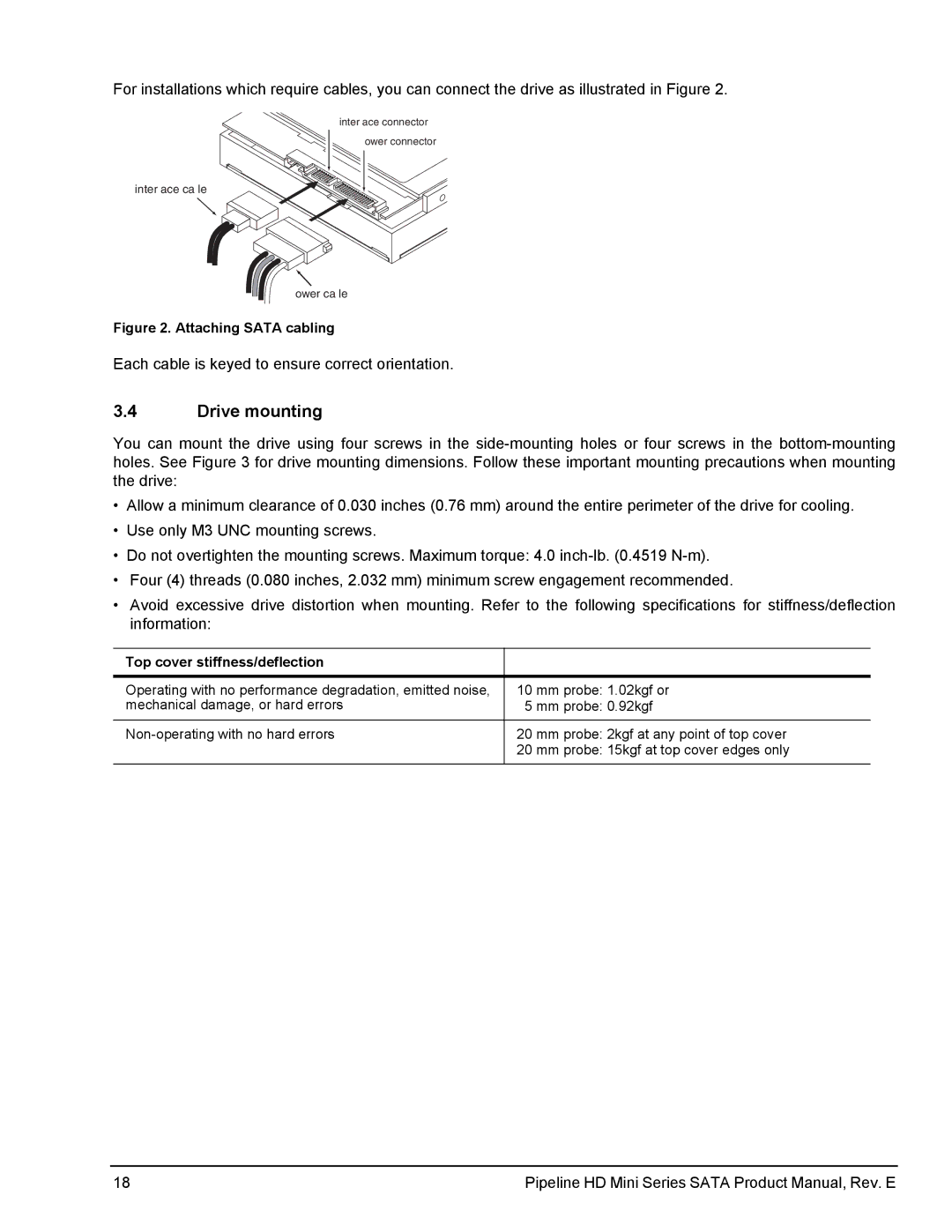

For installations which require cables, you can connect the drive as illustrated in Figure 2.

inter ace connector

ower connector

inter ace ca le

ower ca le

Figure 2. Attaching SATA cabling

Each cable is keyed to ensure correct orientation.

3.4Drive mounting

You can mount the drive using four screws in the

•Allow a minimum clearance of 0.030 inches (0.76 mm) around the entire perimeter of the drive for cooling.

•Use only M3 UNC mounting screws.

•Do not overtighten the mounting screws. Maximum torque: 4.0

•Four (4) threads (0.080 inches, 2.032 mm) minimum screw engagement recommended.

•Avoid excessive drive distortion when mounting. Refer to the following specifications for stiffness/deflection information:

Top cover stiffness/deflection |

|

|

|

Operating with no performance degradation, emitted noise, | 10 mm probe: 1.02kgf or |

mechanical damage, or hard errors | 5 mm probe: 0.92kgf |

|

|

20 mm probe: 2kgf at any point of top cover | |

| 20 mm probe: 15kgf at top cover edges only |

|

|

18 | Pipeline HD Mini Series SATA Product Manual, Rev. E |