SERVICE AND MAINTENANCE

Checking Spark Plug

Check spark plug yearly or every 100 operating hours

1.Clean area around spark plug.

2.Remove and inspect spark plug.

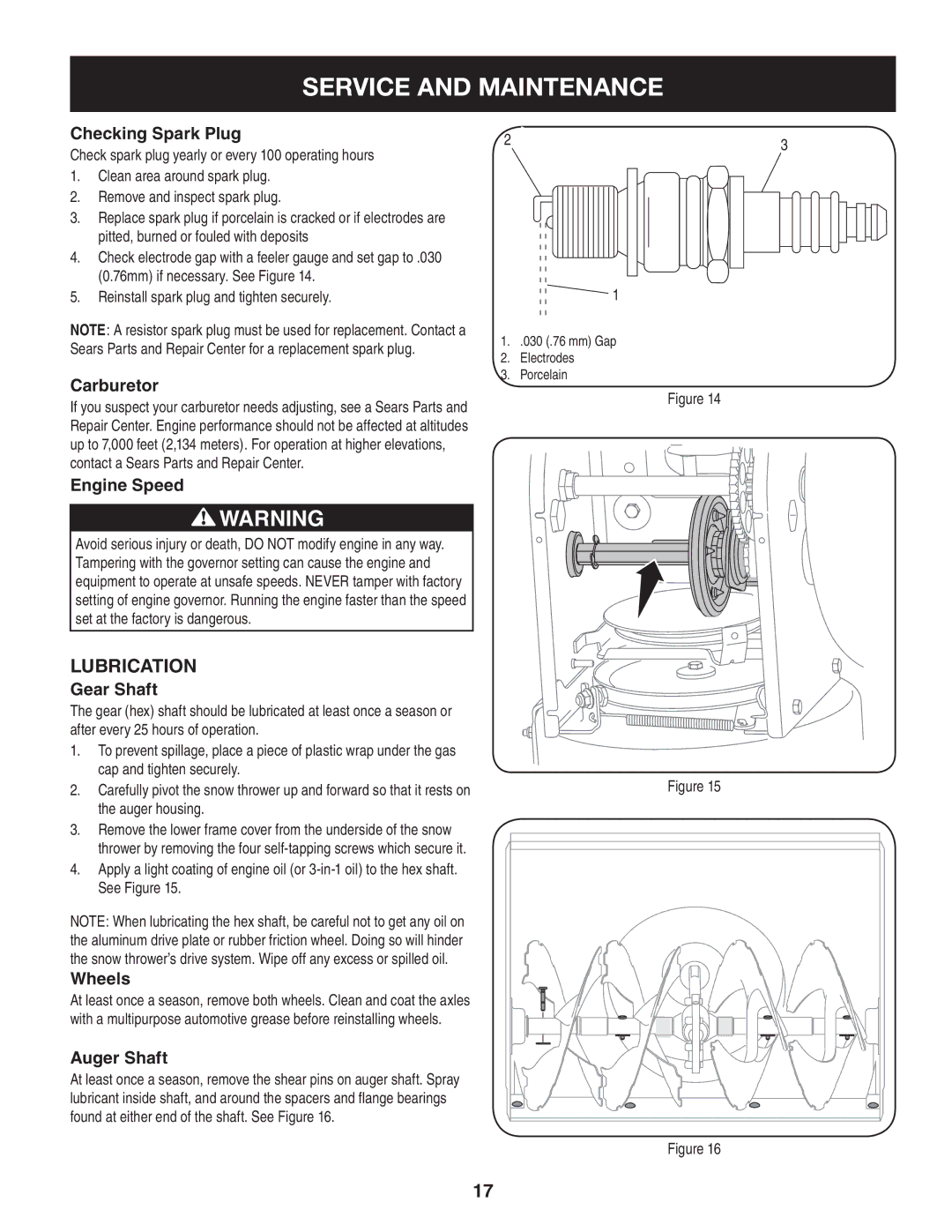

3.Replace spark plug if porcelain is cracked or if electrodes are pitted, burned or fouled with deposits

4.Check electrode gap with a feeler gauge and set gap to .030 (0.76mm) if necessary. See Figure 14.

5.Reinstall spark plug and tighten securely.

NOTE: A resistor spark plug must be used for replacement. Contact a Sears Parts and Repair Center for a replacement spark plug.

Carburetor

If you suspect your carburetor needs adjusting, see a Sears Parts and Repair Center. Engine performance should not be affected at altitudes up to 7,000 feet (2,134 meters). For operation at higher elevations, contact a Sears Parts and Repair Center.

Engine Speed

![]() WARNING

WARNING

Avoid serious injury or death, DO NOT modify engine in any way. Tampering with the governor setting can cause the engine and equipment to operate at unsafe speeds. NEVER tamper with factory setting of engine governor. Running the engine faster than the speed set at the factory is dangerous.

Lubrication

Gear Shaft

The gear (hex) shaft should be lubricated at least once a season or after every 25 hours of operation.

1.To prevent spillage, place a piece of plastic wrap under the gas cap and tighten securely.

2.Carefully pivot the snow thrower up and forward so that it rests on the auger housing.

3.Remove the lower frame cover from the underside of the snow thrower by removing the four

4.Apply a light coating of engine oil (or

NOTE: When lubricating the hex shaft, be careful not to get any oil on the aluminum drive plate or rubber friction wheel. Doing so will hinder the snow thrower’s drive system. Wipe off any excess or spilled oil.

Wheels

At least once a season, remove both wheels. Clean and coat the axles with a multipurpose automotive grease before reinstalling wheels.

Auger Shaft

At least once a season, remove the shear pins on auger shaft. Spray lubricant inside shaft, and around the spacers and flange bearings found at either end of the shaft. See Figure 16.

2 | 3 |

|

1

1. .030 (.76 mm) Gap

2.Electrodes

3.Porcelain

Figure 14

Figure 15

Figure 16

17