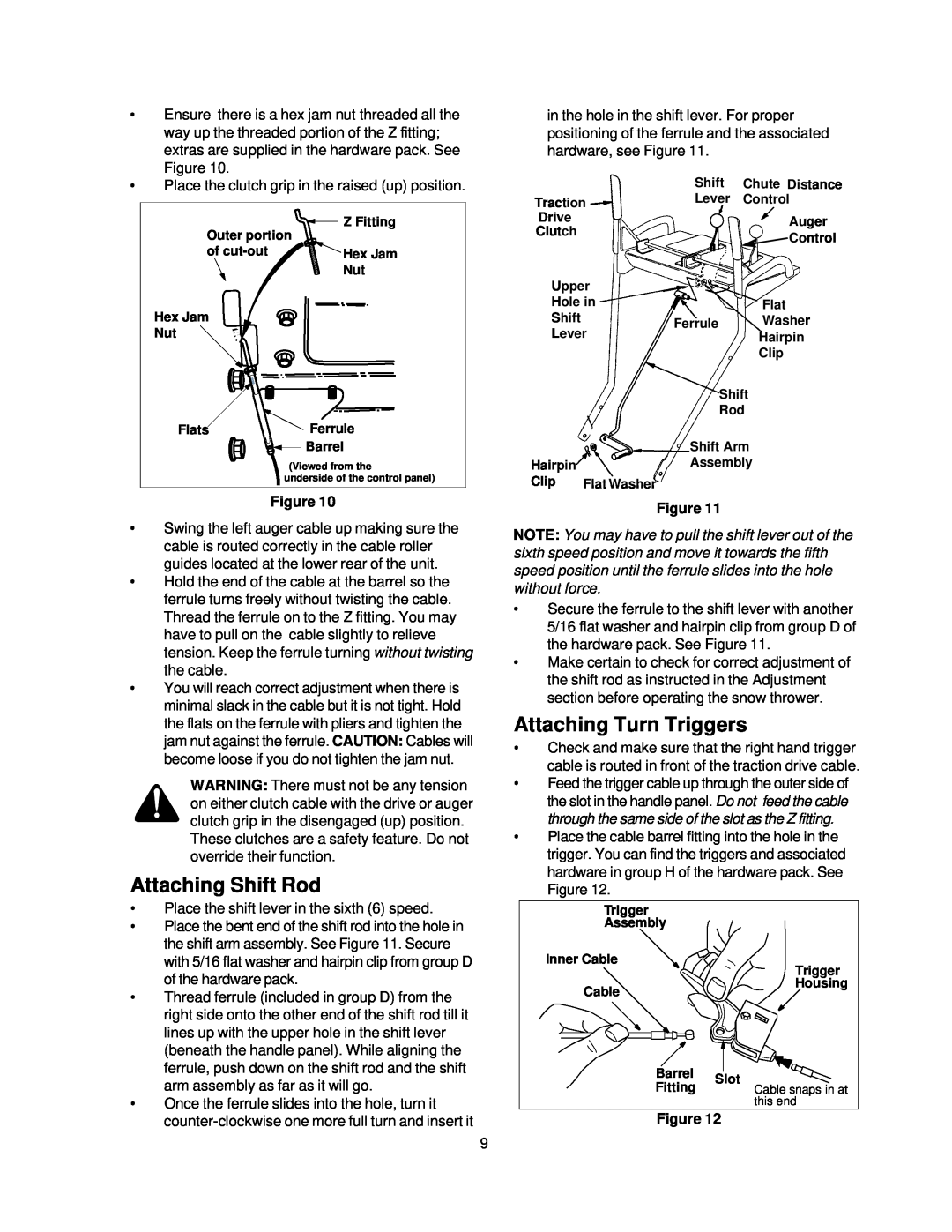

•Ensure there is a hex jam nut threaded all the way up the threaded portion of the Z fitting; extras are supplied in the hardware pack. See Figure 10.

•Place the clutch grip in the raised (up) position.

| Z Fitting |

Outer portion | |

of | Hex Jam |

| Nut |

Hex Jam |

|

Nut |

|

Flats | Ferrule |

| Barrel |

| (Viewed from the |

| underside of the control panel) |

Figure 10

•Swing the left auger cable up making sure the cable is routed correctly in the cable roller guides located at the lower rear of the unit.

•Hold the end of the cable at the barrel so the ferrule turns freely without twisting the cable. Thread the ferrule on to the Z fitting. You may have to pull on the cable slightly to relieve tension. Keep the ferrule turning without twisting the cable.

•You will reach correct adjustment when there is minimal slack in the cable but it is not tight. Hold the flats on the ferrule with pliers and tighten the jam nut against the ferrule. CAUTION: Cables will become loose if you do not tighten the jam nut.

WARNING: There must not be any tension on either clutch cable with the drive or auger clutch grip in the disengaged (up) position.

These clutches are a safety feature. Do not override their function.

Attaching Shift Rod

•Place the shift lever in the sixth (6) speed.

•Place the bent end of the shift rod into the hole in the shift arm assembly. See Figure 11. Secure with 5/16 flat washer and hairpin clip from group D of the hardware pack.

•Thread ferrule (included in group D) from the right side onto the other end of the shift rod till it lines up with the upper hole in the shift lever (beneath the handle panel). While aligning the ferrule, push down on the shift rod and the shift arm assembly as far as it will go.

•Once the ferrule slides into the hole, turn it

in the hole in the shift lever. For proper positioning of the ferrule and the associated hardware, see Figure 11.

|

| Shift | Chute Distance |

Traction | Lever | Control | |

Drive |

|

| Auger |

Clutch |

|

| |

|

| Control | |

|

|

| |

Upper |

|

| |

Hole in |

| Flat | |

Shift |

| Ferrule | Washer |

Lever |

| Hairpin | |

|

|

| |

|

|

| Clip |

|

| Shift | |

|

| Rod | |

|

| Shift Arm | |

Hairpin |

| Assembly | |

Clip | Flat Washer |

|

|

Figure 11

NOTE: You may have to pull the shift lever out of the sixth speed position and move it towards the fifth speed position until the ferrule slides into the hole without force.

•Secure the ferrule to the shift lever with another 5/16 flat washer and hairpin clip from group D of the hardware pack. See Figure 11.

•Make certain to check for correct adjustment of the shift rod as instructed in the Adjustment section before operating the snow thrower.

Attaching Turn Triggers

•Check and make sure that the right hand trigger cable is routed in front of the traction drive cable.

•Feed the trigger cable up through the outer side of the slot in the handle panel. Do not feed the cable through the same side of the slot as the Z fitting.

•Place the cable barrel fitting into the hole in the trigger. You can find the triggers and associated hardware in group H of the hardware pack. See Figure 12.

Trigger |

| |

Assembly |

| |

Inner Cable | Trigger | |

| ||

Cable | Housing | |

| ||

Barrel | Slot | |

Fitting | ||

Cable snaps in at | ||

| this end |

Figure 12

9