MAINTENANCE

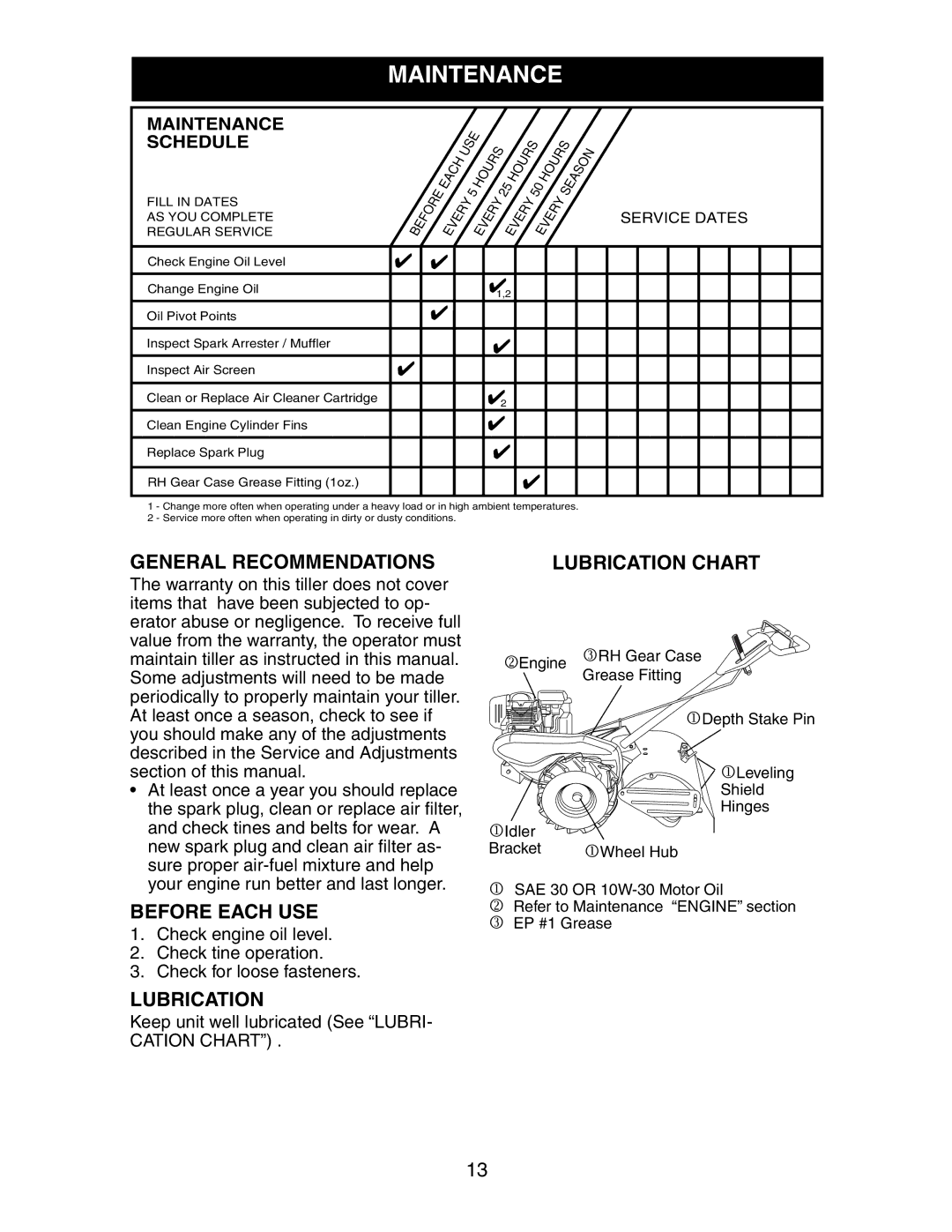

MAINTENANCE SCHEDULE

FILL IN DATES

AS YOU COMPLETE REGULAR SERVICE

| EACH | USE | HOURS |

| HOURS |

| HOURSSEASON |

BEFORE |

| 25 | 50 | ||||

EVERY | EVERY |

| EVERY |

| EVERY | ||

SERVICE DATES

Check Engine Oil Level |

|

Change Engine Oil | 1,2 |

| |

Oil Pivot Points |

|

|

|

Inspect Spark Arrester / Muffler |

|

|

|

Inspect Air Screen |

|

|

|

Clean or Replace Air Cleaner Cartridge | 2 |

| |

Clean Engine Cylinder Fins |

|

|

|

Replace Spark Plug |

|

|

|

RH Gear Case Grease Fitting (1oz.) |

|

1 - Change more often when operating under a heavy load or in high ambient temperatures. 2 - Service more often when operating in dirty or dusty conditions.

GENERAL RECOMMENDATIONS

The warranty on this tiller does not cover items that have been subjected to op- erator abuse or negligence. To receive full value from the warranty, the operator must maintain tiller as instructed in this manual. Some adjustments will need to be made periodically to properly maintain your tiller. At least once a season, check to see if you should make any of the adjustments described in the Service and Adjustments section of this manual.

•At least once a year you should replace the spark plug, clean or replace air filter, and check tines and belts for wear. A new spark plug and clean air filter as- sure proper

BEFORE EACH USE

1.Check engine oil level.

2.Check tine operation.

3.Check for loose fasteners.

LUBRICATION

Keep unit well lubricated (See “LUBRI- CATION CHART”) .

LUBRICATION CHART

2Engine 3RH Gear Case

Grease Fitting

1Depth Stake Pin

1Leveling Shield Hinges

1Idler |

|

Bracket | 1Wheel Hub |

1SAE 30 OR

2Refer to Maintenance “ENGINE” section

3 EP #1 Grease

13