ASSEMBLY/PRE-OPERATION

Your new tiller has been assembled at the factory with the exception of those parts left unassembled for shipping purposes. To ensure safe and proper operation of your tiller all parts and hardware you assemble must be tightened securely. Use the correct tools as necessary to insure proper tightness.

TOOLS REQUIRED FOR

ASSEMBLY

A socket wrench set will make assembly easier. Standard wrench sizes are listed.

(1)Utility knife

(1)Wire cutter

(1)Tire pressure gauge

(1)Screwdriver

(1)Pair of pliers

(1)9/16" wrench

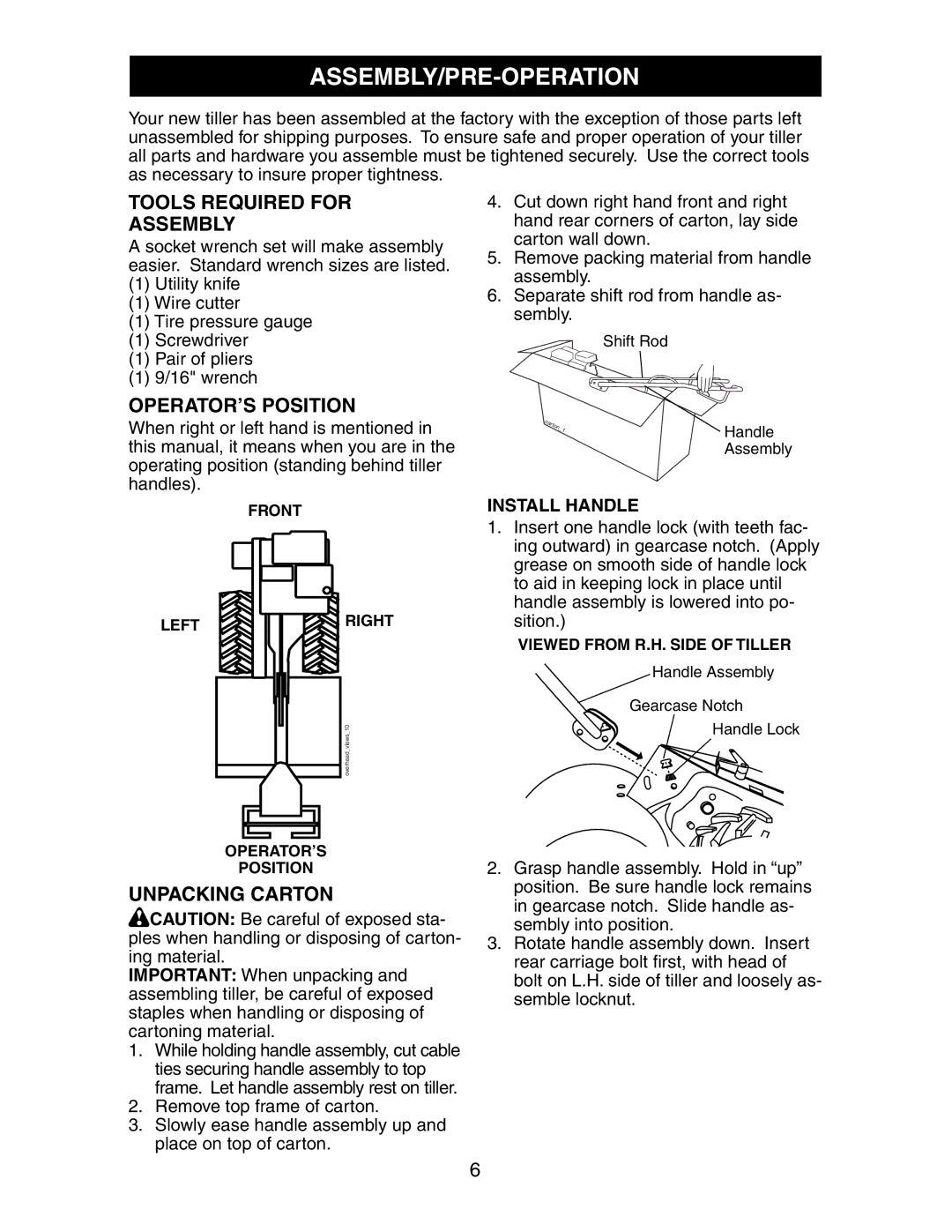

OPERATOR’S POSITION

When right or left hand is mentioned in this manual, it means when you are in the operating position (standing behind tiller handles).

FRONT

LEFT | RIGHT |

| |

| overhead views 10 |

OPERATOR’S

POSITION

UNPACKING CARTON

![]() CAUTION: Be careful of exposed sta- ples when handling or disposing of carton- ing material.

CAUTION: Be careful of exposed sta- ples when handling or disposing of carton- ing material.

IMPORTANT: When unpacking and assembling tiller, be careful of exposed staples when handling or disposing of cartoning material.

1.While holding handle assembly, cut cable ties securing handle assembly to top frame. Let handle assembly rest on tiller.

2.Remove top frame of carton.

3.Slowly ease handle assembly up and place on top of carton.

4.Cut down right hand front and right hand rear corners of carton, lay side carton wall down.

5.Remove packing material from handle assembly.

6.Separate shift rod from handle as- sembly.

Shift Rod

Handle

Assembly

INSTALL HANDLE

1.Insert one handle lock (with teeth fac- ing outward) in gearcase notch. (Apply grease on smooth side of handle lock to aid in keeping lock in place until handle assembly is lowered into po- sition.)

VIEWED FROM R.H. SIDE OF TILLER

Handle Assembly

Gearcase Notch

Handle Lock

2.Grasp handle assembly. Hold in “up” position. Be sure handle lock remains in gearcase notch. Slide handle as- sembly into position.

3.Rotate handle assembly down. Insert rear carriage bolt first, with head of bolt on L.H. side of tiller and loosely as- semble locknut.

6