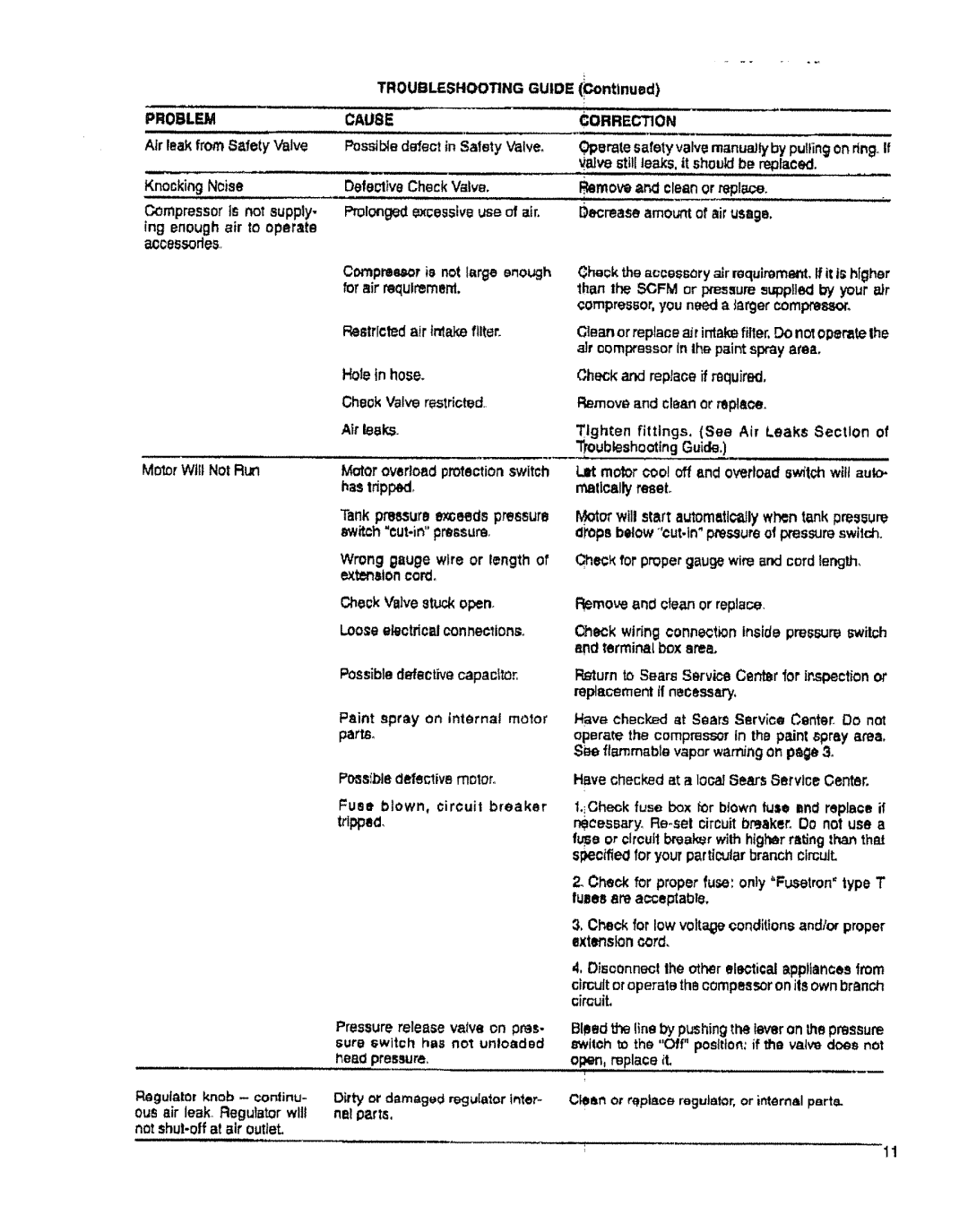

PROBLEM

Air leak fror_S_,fety Valve

KnockingN_ise

Compressorisnotsupply- ingenough airtooperate _ocessorl_s,

TROUBLESHOOTING GUIDE (Continued)

CAUSE |

| CORRECTION |

Possibledefect in Salety Valve. | (_rate safety valvemanuaJlyby pulting on dngoif | |

|

| vaJvestill ieaks, it shouldbe re_laced. |

Defective Check Valves. |

| i_move and clean or repl_ce. |

v_,,,,,,,_,,,,,,_ | , , | |

Prolongedexcessive use of air. | 0ecrease amount of air usage. | |

Compressor is not large | enough | Check the accessoryair requimmerd.If it is higher |

for air requirement. |

| than the SCFM or pressure supplied by your a_r |

|

| compressor, you need a _argercompressor. |

| Restrictedair intake filter. |

| Holetn hose. |

| Cheek Valve restricted., |

| Air leaks. |

| .... |

Molor Wllt Not Rurl | Motor overloadprotectionswitch |

| has tripped° |

| Tank pressure exceeds pressure |

| _witch |

| Wrong gauge wire or length of |

| extensioncord, |

| Check Valvestuck open. |

| Loose electrical connecltonso |

| Possibledefective capacitor, |

| Paint spray on internal motor |

| parts. |

| Possible defective motor, |

| Fuse blown, circuit breaker |

| tripped, |

Cleanor replaceair intakefiller, Do nc_operateIhe air compressorin lhe paint spray area.

Check and replace if required,

Remove snd clean or r_place,.

Tighten fittings, (See Air Leaks Section of _ubleshooting Guide.)

Lit motorcoo! off and overloads_tch wtft auto- n',atlcsllyreseL

Motor will start automatlc_Jiywhen tank 1oreseure drops below

Che¢_ forproper gauge wire and cord length,

Remove and clea.n or replace_

Check wiring connection inside pressure switch and terminal box area.

Return to Sears Service Centertor ir.spectionor replacement if necessary,

Have check,L_ at Sears Service Center. Do not

operate the compressorin the paint spray area, Si_eflammable vapor wartungon p_ge 3.

Have checked at a Ioce_Sears Servlce Center.

t._Che_kfuse box _r btownfuse randreplace if necessary.

2.Check for proper fuse: only 'Fusetren"type T fuses are acceptable,

R_guiator knob - coninu-

OUSsir leak,, Regulator wltl not

| 3, Check for low voltageconditionsandtor proper |

| extensioncord. |

| 4,Disoonnecl the other elec_icaiappliancesfrom |

| ctmult or operate theoompessoron itsown branch |

| cir_uiL |

Pressurerelease vatve on _res. | Bleed the fineby pushingthe leveron thepressure |

sure switch has no1 unloaded | switch to the "Off" position;if the vaive does not |

I_ea0pressure, | open, replace it |

Dirty or damaged re_ju_a_orinter- | Cle_n or r_ptace regulator, or internal parts. |

nal p_,rts, |

|