ASSEMBLY

================================================================================================

| CAUTION: Gloves are required when handling |

|

|

|

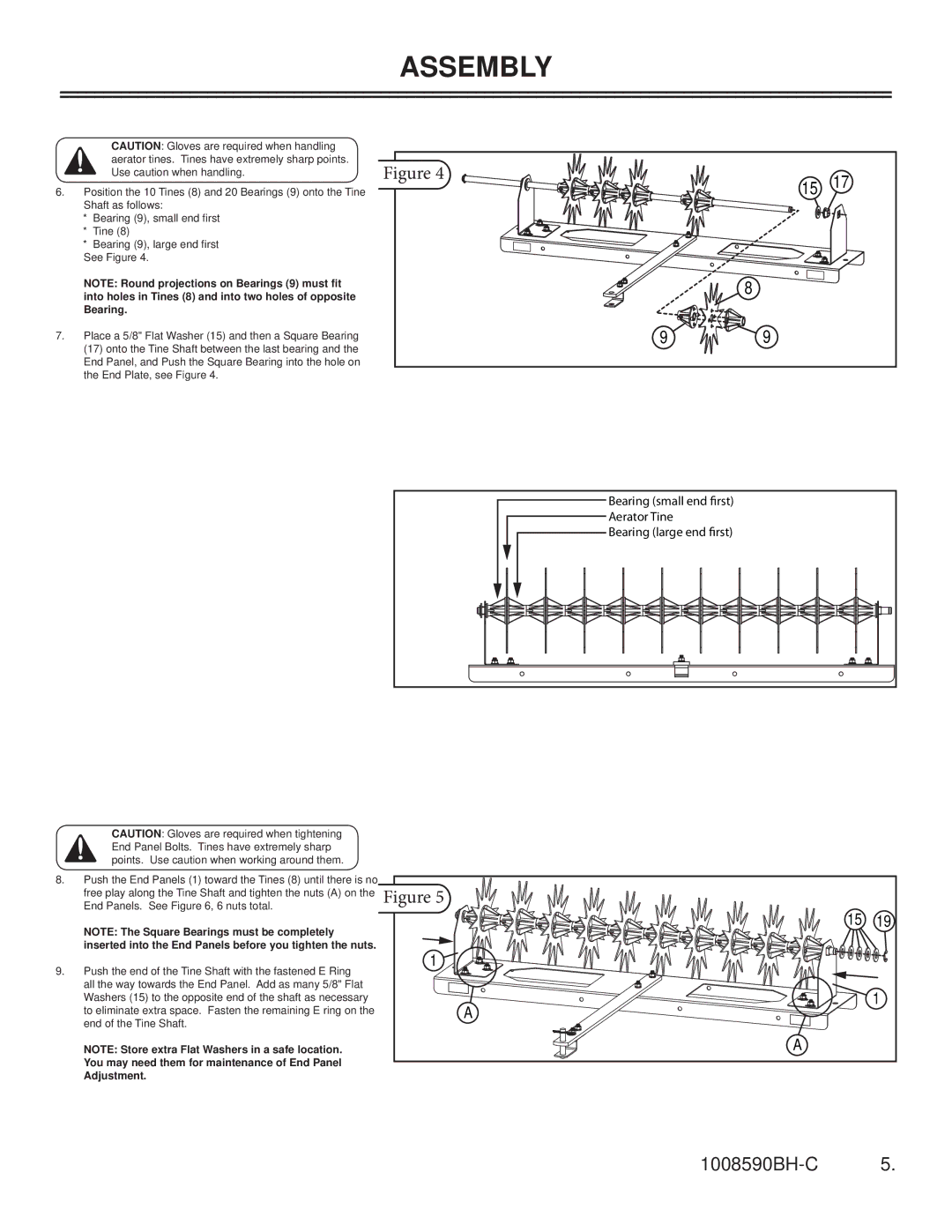

| aerator tines. Tines have extremely sharp points. | Figure 4 |

|

|

| Use caution when handling. | 15 | 17 | |

6. Position the 10 Tines (8) and 20 Bearings (9) onto the Tine |

| |||

Shaft as follows: |

|

|

| |

* | Bearing (9), small end first |

|

|

|

* | Tine (8) |

|

|

|

* | Bearing (9), large end first |

|

|

|

See Figure 4. |

|

|

| |

NOTE: Round projections on Bearings (9) must fit |

| 8 |

| |

into holes in Tines (8) and into two holes of opposite |

|

| ||

|

|

| ||

Bearing. |

|

|

| |

7. Place a 5/8" Flat Washer (15) and then a Square Bearing | 9 | 9 |

| |

(17) onto the Tine Shaft between the last bearing and the |

|

|

| |

End Panel, and Push the Square Bearing into the hole on |

|

|

| |

the End Plate, see Figure 4. |

|

|

| |

Bearing (small end first) |

Aerator Tine |

Bearing (large end first) |

CAUTION: Gloves are required when tightening End Panel Bolts. Tines have extremely sharp points. Use caution when working around them.

8.Push the End Panels (1) toward the Tines (8) until there is no free play along the Tine Shaft and tighten the nuts (A) on the End Panels. See Figure 6, 6 nuts total.

NOTE: The Square Bearings must be completely inserted into the End Panels before you tighten the nuts.

9.Push the end of the Tine Shaft with the fastened E Ring all the way towards the End Panel. Add as many 5/8" Flat Washers (15) to the opposite end of the shaft as necessary to eliminate extra space. Fasten the remaining E ring on the end of the Tine Shaft.

NOTE: Store extra Flat Washers in a safe location. You may need them for maintenance of End Panel Adjustment.

Figure 5 |

|

15 | 19 |

1 |

|

A | 1 |

| |

A |

|