SC2, M2, M3, SC1, SNS50 specifications

The Senco SNS50, SC1, M3, M2, and SC2 are part of an innovative lineup of tools designed for professional contractors and DIY enthusiasts alike, featuring advanced technologies and high-performance characteristics that set them apart in the market.The Senco SNS50 is an innovative cordless nailer that offers superior power and precision for driving nails in various applications. It uses advanced battery technology to deliver consistent performance without the hassle of cords and compressors. The tool is lightweight, ergonomic, and features a tool-free depth adjustment for optimal results. Its integrated LED light helps illuminate dark work areas, which enhances visibility and accuracy.

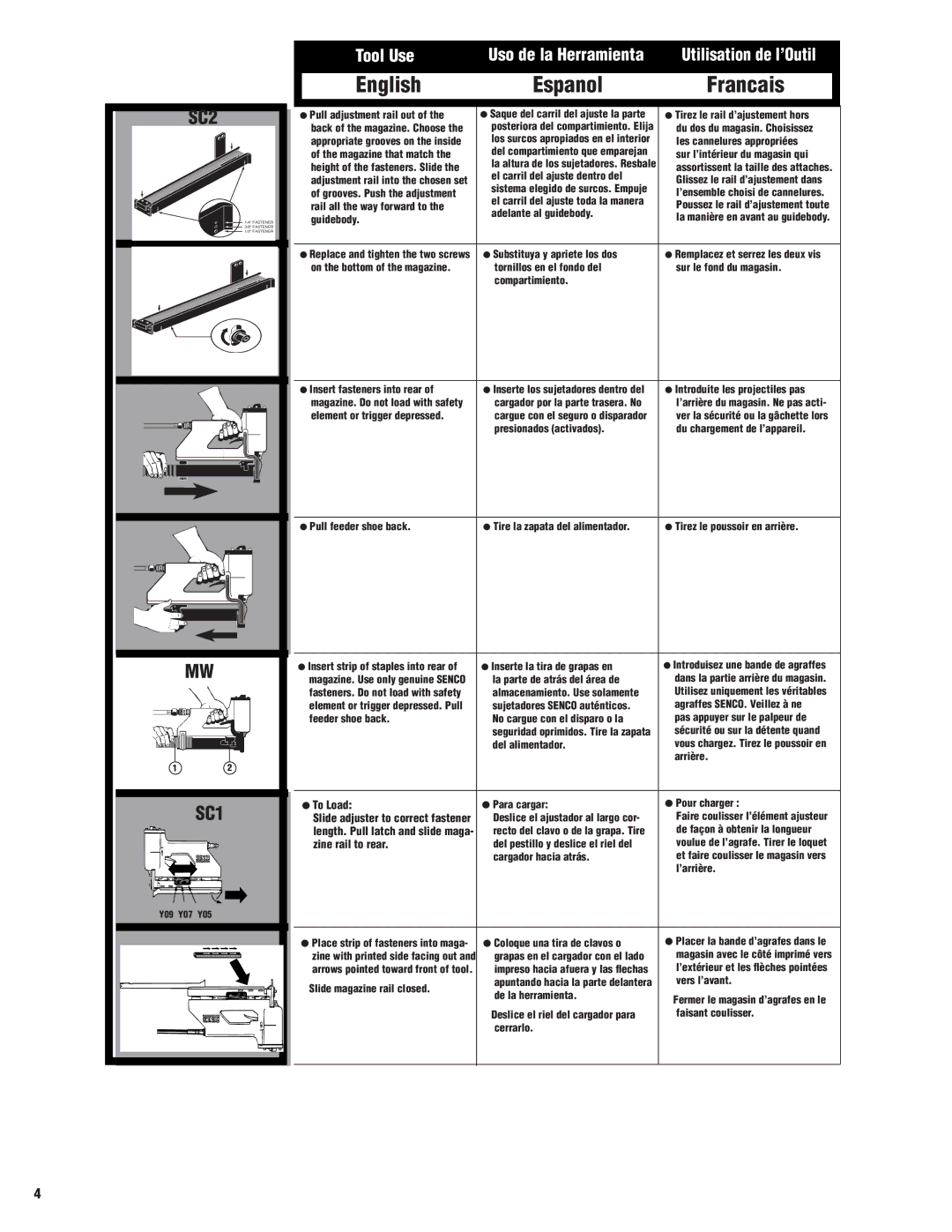

The SC1 and SC2 models are designed for efficiency and versatility. Both nailers leverage Senco's Smart Point technology, which allows for easier nail placement and reduces the chances of misfires. The SC1 model is particularly advantageous for trimming applications, as it is able to drive 18-gauge finish nails with precision. The SC2, on the other hand, is perfect for larger projects, such as fencing and decking, due to its capability of driving heavier gauge nails.

For those who require a robust solution for heavier tasks, the M3 and M2 models stand out with their powerful pneumatic functionality. The M3 is engineered for high-volume nailing, boasting a rapid-fire mode that enhances productivity on large job sites. Its adjustable exhaust allows for better control of air flow, and its built-in air duster keeps the work area clean. The M2 complements this with a designed focus on mid-range applications, offering versatility in nail lengths and types while maintaining a lightweight form factor.

Each of these tools incorporates Senco’s renowned durability, ensuring they can withstand the rigors of daily use without compromising performance. Key characteristics include user-friendly controls, quick-release nose pieces for easy clearing of jams, and robust safety features to protect users during operation.

In summary, whether you're a professional contractor or a passionate DIYer, Senco's SNS50, SC1, SC2, M3, and M2 models provide a range of features and technologies that cater to a variety of nailing needs, delivering efficiency, precision, and reliability in every project.