OPERATION

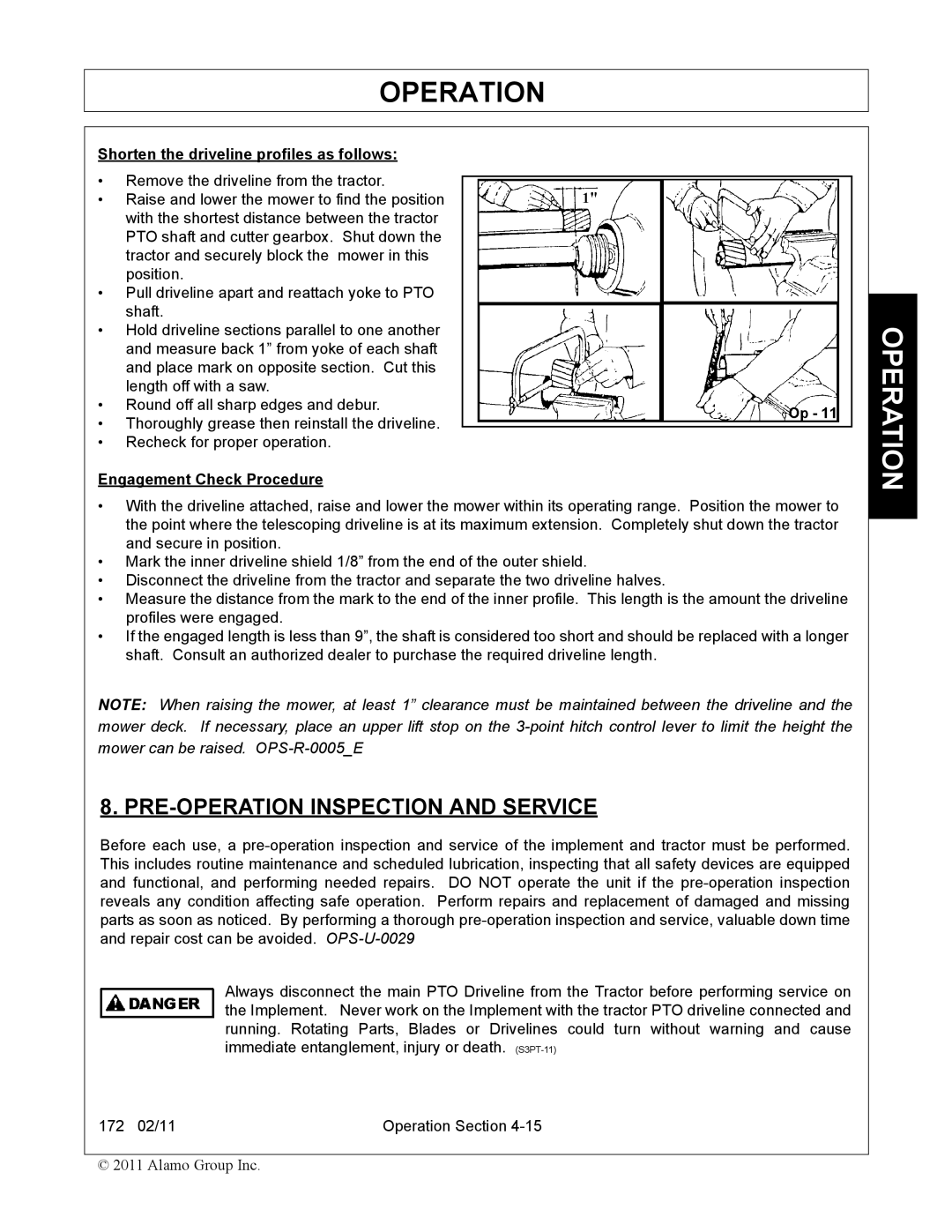

Shorten the driveline profiles as follows:

•Remove the driveline from the tractor.

•Raise and lower the mower to find the position with the shortest distance between the tractor PTO shaft and cutter gearbox. Shut down the tractor and securely block the mower in this position.

•Pull driveline apart and reattach yoke to PTO shaft.

•Hold driveline sections parallel to one another and measure back 1” from yoke of each shaft and place mark on opposite section. Cut this length off with a saw.

•Round off all sharp edges and debur.

•Thoroughly grease then reinstall the driveline.

•Recheck for proper operation.

Engagement Check Procedure

•With the driveline attached, raise and lower the mower within its operating range. Position the mower to the point where the telescoping driveline is at its maximum extension. Completely shut down the tractor and secure in position.

•Mark the inner driveline shield 1/8” from the end of the outer shield.

•Disconnect the driveline from the tractor and separate the two driveline halves.

•Measure the distance from the mark to the end of the inner profile. This length is the amount the driveline profiles were engaged.

•If the engaged length is less than 9”, the shaft is considered too short and should be replaced with a longer shaft. Consult an authorized dealer to purchase the required driveline length.

NOTE: When raising the mower, at least 1” clearance must be maintained between the driveline and the mower deck. If necessary, place an upper lift stop on the

8. PRE-OPERATION INSPECTION AND SERVICE

Before each use, a

Always disconnect the main PTO Driveline from the Tractor before performing service on the Implement. Never work on the Implement with the tractor PTO driveline connected and running. Rotating Parts, Blades or Drivelines could turn without warning and cause immediate entanglement, injury or death.

172 02/11 | Operation Section |

© 2011 Alamo Group Inc.