MAINTENANCE

MAINTENANCE

Lubrication Information

Before operating your Loader, take the time to inspect and repair any damage to the machine or tractor. Only a minimum of time and effort is required to regularly maintain this machine to provide long life and trouble free operation.

Do not operate this Equipment with hydraulic oil or fuel leaking. Oil and fuel are explosive and their presence could present a hazard. Do not check for leaks with your hand!

.

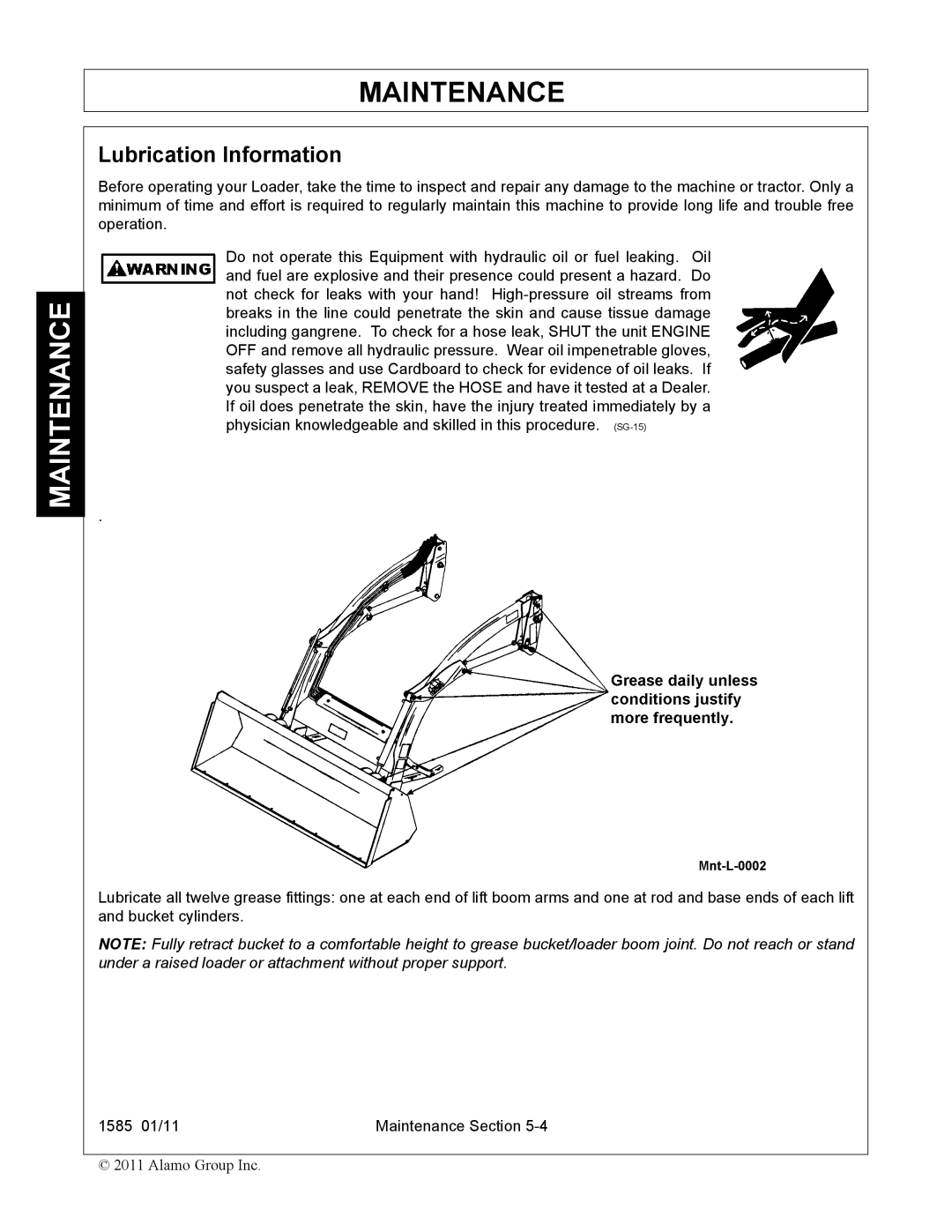

Lubricate all twelve grease fittings: one at each end of lift boom arms and one at rod and base ends of each lift and bucket cylinders.

NOTE: Fully retract bucket to a comfortable height to grease bucket/loader boom joint. Do not reach or stand under a raised loader or attachment without proper support.

1585 01/11 | Maintenance Section |

© 2011 Alamo Group Inc.