OPERATION

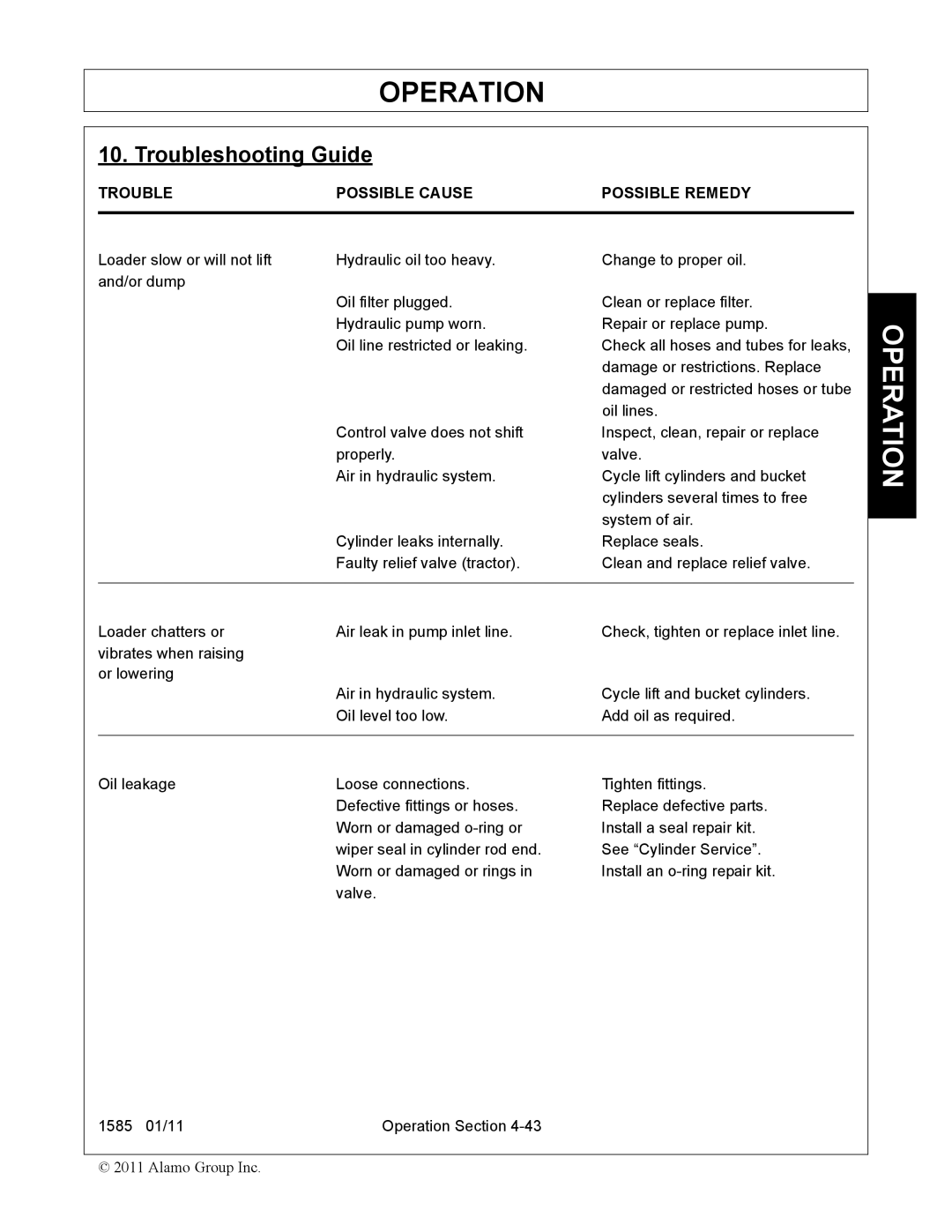

10. Troubleshooting Guide

TROUBLE | POSSIBLE CAUSE | POSSIBLE REMEDY |

|

|

|

Loader slow or will not lift | Hydraulic oil too heavy. | Change to proper oil. |

and/or dump | Oil filter plugged. | Clean or replace filter. |

| ||

| Hydraulic pump worn. | Repair or replace pump. |

| Oil line restricted or leaking. | Check all hoses and tubes for leaks, |

|

| damage or restrictions. Replace |

|

| damaged or restricted hoses or tube |

|

| oil lines. |

| Control valve does not shift | Inspect, clean, repair or replace |

| properly. | valve. |

| Air in hydraulic system. | Cycle lift cylinders and bucket |

|

| cylinders several times to free |

|

| system of air. |

| Cylinder leaks internally. | Replace seals. |

| Faulty relief valve (tractor). | Clean and replace relief valve. |

|

|

|

Loader chatters or | Air leak in pump inlet line. | Check, tighten or replace inlet line. |

vibrates when raising |

|

|

or lowering | Air in hydraulic system. | Cycle lift and bucket cylinders. |

| ||

| Oil level too low. | Add oil as required. |

|

|

|

OPERATION

Oil leakage | Loose connections. |

| Defective fittings or hoses. |

| Worn or damaged |

| wiper seal in cylinder rod end. |

| Worn or damaged or rings in |

| valve. |

Tighten fittings. Replace defective parts. Install a seal repair kit. See “Cylinder Service”. Install an

1585 01/11 | Operation Section |

© 2011 Alamo Group Inc.