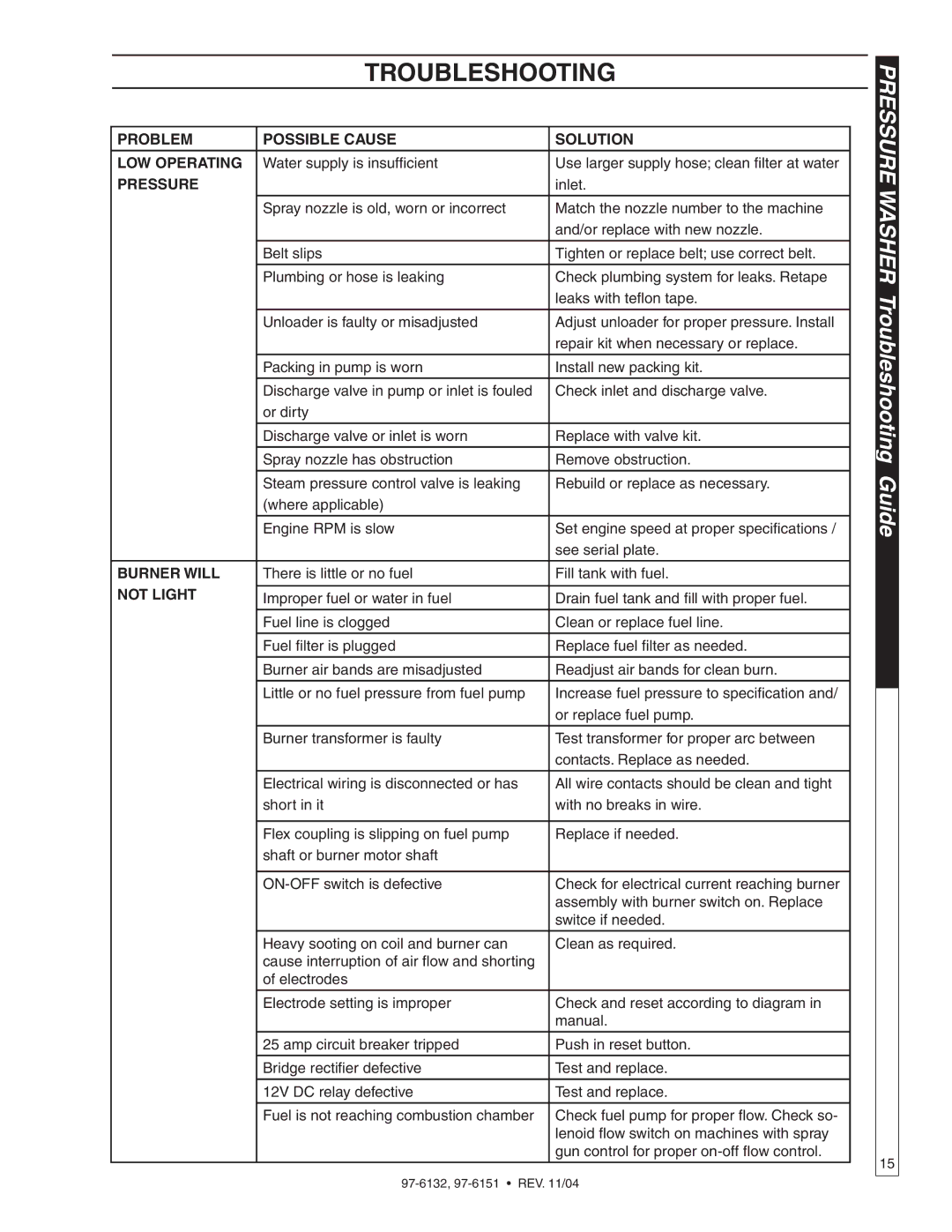

TROUBLESHOOTING

PROBLEM | POSSIBLE CAUSE | SOLUTION |

LOW OPERATING | Water supply is insufficient | Use larger supply hose; clean filter at water |

PRESSURE |

| inlet. |

|

|

|

| Spray nozzle is old, worn or incorrect | Match the nozzle number to the machine |

|

| and/or replace with new nozzle. |

|

|

|

| Belt slips | Tighten or replace belt; use correct belt. |

|

|

|

| Plumbing or hose is leaking | Check plumbing system for leaks. Retape |

|

| leaks with teflon tape. |

|

|

|

| Unloader is faulty or misadjusted | Adjust unloader for proper pressure. Install |

|

| repair kit when necessary or replace. |

|

|

|

| Packing in pump is worn | Install new packing kit. |

|

|

|

| Discharge valve in pump or inlet is fouled | Check inlet and discharge valve. |

| or dirty |

|

|

|

|

| Discharge valve or inlet is worn | Replace with valve kit. |

| Spray nozzle has obstruction | Remove obstruction. |

|

|

|

| Steam pressure control valve is leaking | Rebuild or replace as necessary. |

| (where applicable) |

|

| Engine RPM is slow | Set engine speed at proper specifications / |

|

| see serial plate. |

|

|

|

BURNER WILL | There is little or no fuel | Fill tank with fuel. |

NOT LIGHT |

|

|

Improper fuel or water in fuel | Drain fuel tank and fill with proper fuel. | |

|

|

|

| Fuel line is clogged | Clean or replace fuel line. |

|

|

|

| Fuel filter is plugged | Replace fuel filter as needed. |

| Burner air bands are misadjusted | Readjust air bands for clean burn. |

|

|

|

| Little or no fuel pressure from fuel pump | Increase fuel pressure to specification and/ |

|

| or replace fuel pump. |

| Burner transformer is faulty | Test transformer for proper arc between |

|

| contacts. Replace as needed. |

|

|

|

| Electrical wiring is disconnected or has | All wire contacts should be clean and tight |

| short in it | with no breaks in wire. |

|

|

|

| Flex coupling is slipping on fuel pump | Replace if needed. |

| shaft or burner motor shaft |

|

|

|

|

| Check for electrical current reaching burner | |

|

| assembly with burner switch on. Replace |

|

| switce if needed. |

|

|

|

| Heavy sooting on coil and burner can | Clean as required. |

| cause interruption of air flow and shorting |

|

| of electrodes |

|

|

|

|

| Electrode setting is improper | Check and reset according to diagram in |

|

| manual. |

|

|

|

| 25 amp circuit breaker tripped | Push in reset button. |

|

|

|

| Bridge rectifier defective | Test and replace. |

| 12V DC relay defective | Test and replace. |

|

|

|

| Fuel is not reaching combustion chamber | Check fuel pump for proper flow. Check so- |

|

| lenoid flow switch on machines with spray |

|

| gun control for proper |

|

|

|

PRESSURE WASHER Troubleshooting Guide

15