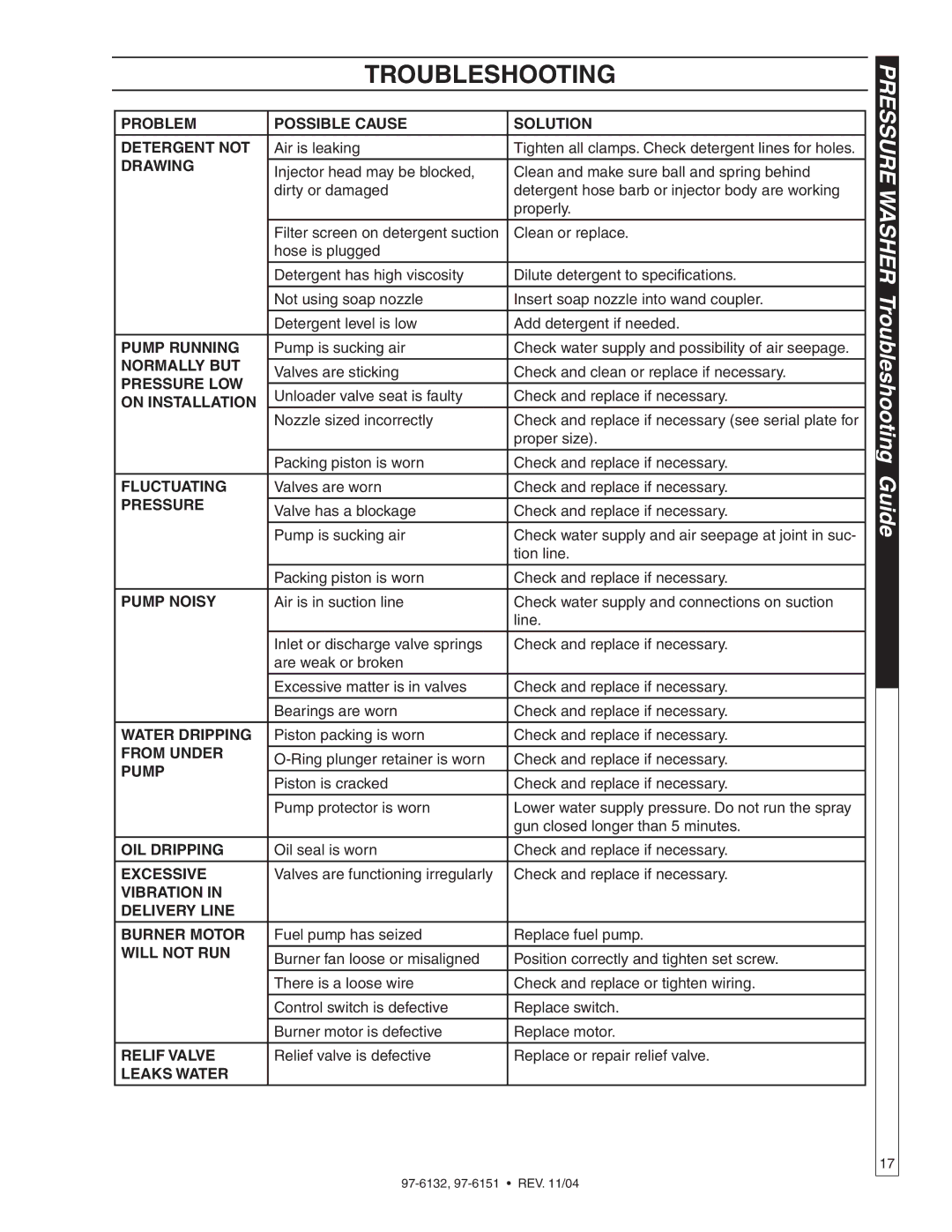

TROUBLESHOOTING

PROBLEM | POSSIBLE CAUSE | SOLUTION | |

|

|

| |

DETERGENT NOT | Air is leaking | Tighten all clamps. Check detergent lines for holes. | |

DRAWING |

|

| |

Injector head may be blocked, | Clean and make sure ball and spring behind | ||

| |||

| dirty or damaged | detergent hose barb or injector body are working | |

|

| properly. | |

|

|

| |

| Filter screen on detergent suction | Clean or replace. | |

| hose is plugged |

| |

|

|

| |

| Detergent has high viscosity | Dilute detergent to specifications. | |

|

|

| |

| Not using soap nozzle | Insert soap nozzle into wand coupler. | |

| Detergent level is low | Add detergent if needed. | |

|

|

| |

PUMP RUNNING | Pump is sucking air | Check water supply and possibility of air seepage. | |

NORMALLY BUT |

|

| |

Valves are sticking | Check and clean or replace if necessary. | ||

PRESSURE LOW | |||

|

| ||

Unloader valve seat is faulty | Check and replace if necessary. | ||

ON INSTALLATION | |||

| Nozzle sized incorrectly | Check and replace if necessary (see serial plate for | |

|

| proper size). | |

|

|

| |

| Packing piston is worn | Check and replace if necessary. | |

|

|

| |

FLUCTUATING | Valves are worn | Check and replace if necessary. | |

PRESSURE | Valve has a blockage | Check and replace if necessary. | |

| |||

|

|

| |

| Pump is sucking air | Check water supply and air seepage at joint in suc- | |

|

| tion line. | |

| Packing piston is worn | Check and replace if necessary. | |

|

|

| |

PUMP NOISY | Air is in suction line | Check water supply and connections on suction | |

|

| line. | |

| Inlet or discharge valve springs | Check and replace if necessary. | |

| are weak or broken |

| |

|

|

| |

| Excessive matter is in valves | Check and replace if necessary. | |

|

|

| |

| Bearings are worn | Check and replace if necessary. | |

|

|

| |

WATER DRIPPING | Piston packing is worn | Check and replace if necessary. | |

FROM UNDER |

|

| |

Check and replace if necessary. | |||

PUMP | |||

|

| ||

Piston is cracked | Check and replace if necessary. | ||

| |||

|

|

| |

| Pump protector is worn | Lower water supply pressure. Do not run the spray | |

|

| gun closed longer than 5 minutes. | |

|

|

| |

OIL DRIPPING | Oil seal is worn | Check and replace if necessary. | |

|

|

| |

EXCESSIVE | Valves are functioning irregularly | Check and replace if necessary. | |

VIBRATION IN |

|

| |

DELIVERY LINE |

|

| |

BURNER MOTOR | Fuel pump has seized | Replace fuel pump. | |

WILL NOT RUN |

|

| |

Burner fan loose or misaligned | Position correctly and tighten set screw. | ||

| |||

|

|

| |

| There is a loose wire | Check and replace or tighten wiring. | |

|

|

| |

| Control switch is defective | Replace switch. | |

| Burner motor is defective | Replace motor. | |

|

|

| |

RELIF VALVE | Relief valve is defective | Replace or repair relief valve. | |

LEAKS WATER |

|

|

PRESSURE WASHER Troubleshooting Guide

17