Ver. 6.0U _ Sep 6, 2012

For grounding, each PV module has a hole in the frame for either a bolt, nut and washer, a ground lug fastened by bolt or screw, or an appropriate screw (hardware not provided). Installation for wiring and grounding method shall be in accordance with national, regional and local codes, laws, standard, and the relevant instructions below. In a connection of this type, the hardware (such as a star washer) must score the frame surface to make positive electrical contact with the frame. The ground wire must not be smaller than No.12 AWG.

The National Electrical Code (NEC) 690.33 requires that connectors are installed in a readily accessible location, circuits operating at over 30 volts, shall require a tool to open. PV module’s connectors comply with the NEC corresponding section.

Grounding

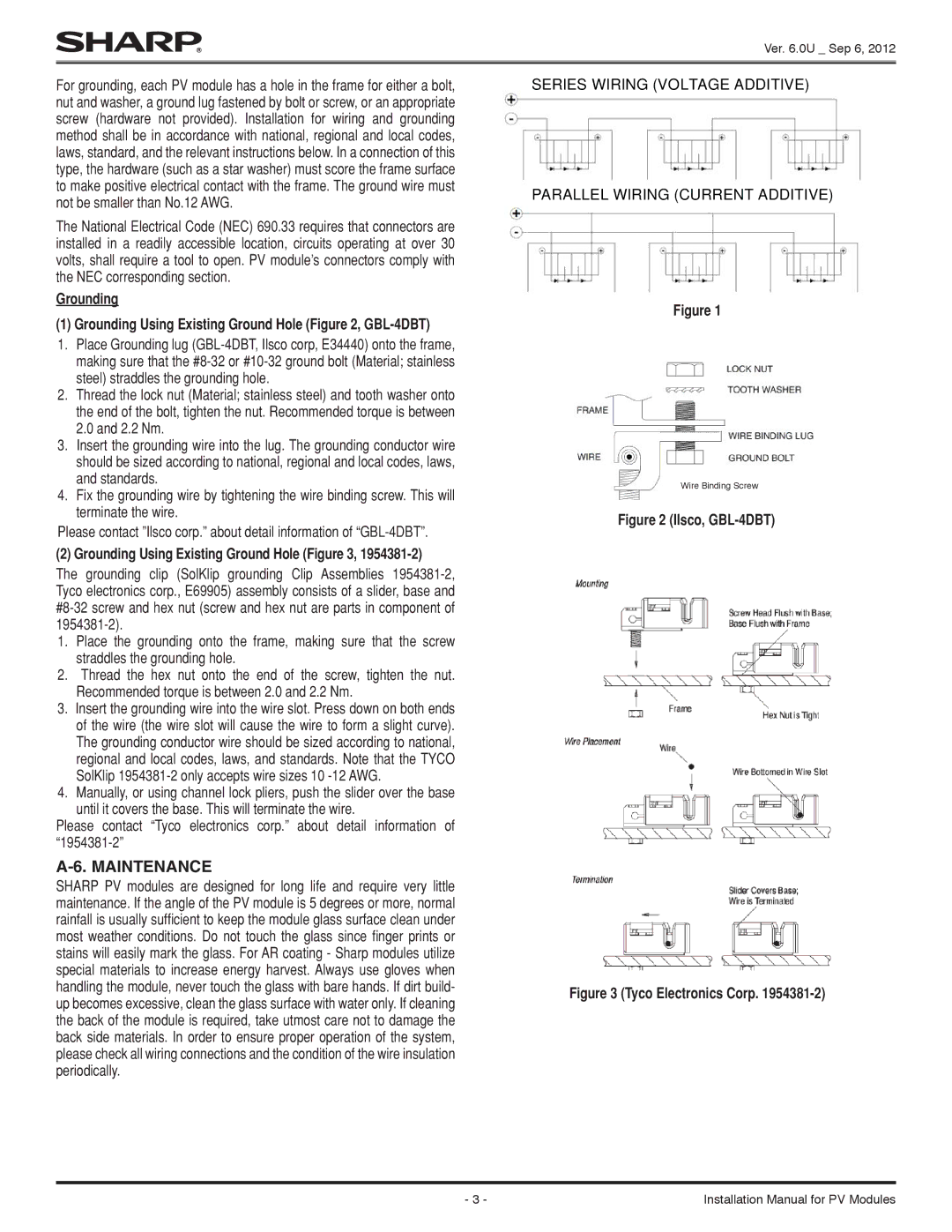

(1) Grounding Using Existing Ground Hole (Figure 2, GBL-4DBT)

1.Place Grounding lug

2.Thread the lock nut (Material; stainless steel) and tooth washer onto the end of the bolt, tighten the nut. Recommended torque is between 2.0 and 2.2 Nm.

3.Insert the grounding wire into the lug. The grounding conductor wire should be sized according to national, regional and local codes, laws, and standards.

4.Fix the grounding wire by tightening the wire binding screw. This will terminate the wire.

Please contact ”Ilsco corp.” about detail information of

(2) Grounding Using Existing Ground Hole (Figure 3, 1954381-2)

The grounding clip (SolKlip grounding Clip Assemblies

1.Place the grounding onto the frame, making sure that the screw straddles the grounding hole.

2.Thread the hex nut onto the end of the screw, tighten the nut. Recommended torque is between 2.0 and 2.2 Nm.

3.Insert the grounding wire into the wire slot. Press down on both ends of the wire (the wire slot will cause the wire to form a slight curve). The grounding conductor wire should be sized according to national, regional and local codes, laws, and standards. Note that the TYCO SolKlip

4.Manually, or using channel lock pliers, push the slider over the base until it covers the base. This will terminate the wire.

Please contact “Tyco electronics corp.” about detail information of

A-6. MAINTENANCE

SHARP PV modules are designed for long life and require very little maintenance. If the angle of the PV module is 5 degrees or more, normal rainfall is usually sufficient to keep the module glass surface clean under most weather conditions. Do not touch the glass since finger prints or stains will easily mark the glass. For AR coating - Sharp modules utilize special materials to increase energy harvest. Always use gloves when handling the module, never touch the glass with bare hands. If dirt build- up becomes excessive, clean the glass surface with water only. If cleaning the back of the module is required, take utmost care not to damage the back side materials. In order to ensure proper operation of the system, please check all wiring connections and the condition of the wire insulation periodically.

SERIES WIRING (VOLTAGE ADDITIVE)

PARALLEL WIRING (CURRENT ADDITIVE)

Figure 1

Figure 1

Wire Binding Screw

Figure 2 (Ilsco, GBL-4DBT)

Figure 3 (Tyco Electronics Corp. 1954381-2)

- 3 - | Installation Manual for PV Modules |