135-Hour Maintenace

Every 135 hours of operation,

remove and clean the muffler.

WARNING!

Never operate the machine with a damaged

or missing muffler or spark arrester! Operating with missing or dam- aged exhaust components is a fire hazard and could also damage your hearing.

1. | Remove the spark plug boot. |

2. | Remove the two 4 mm engine cover |

| screws (located at the top of the recoil |

| housing). |

3. | Loosen the 5 mm engine top cover |

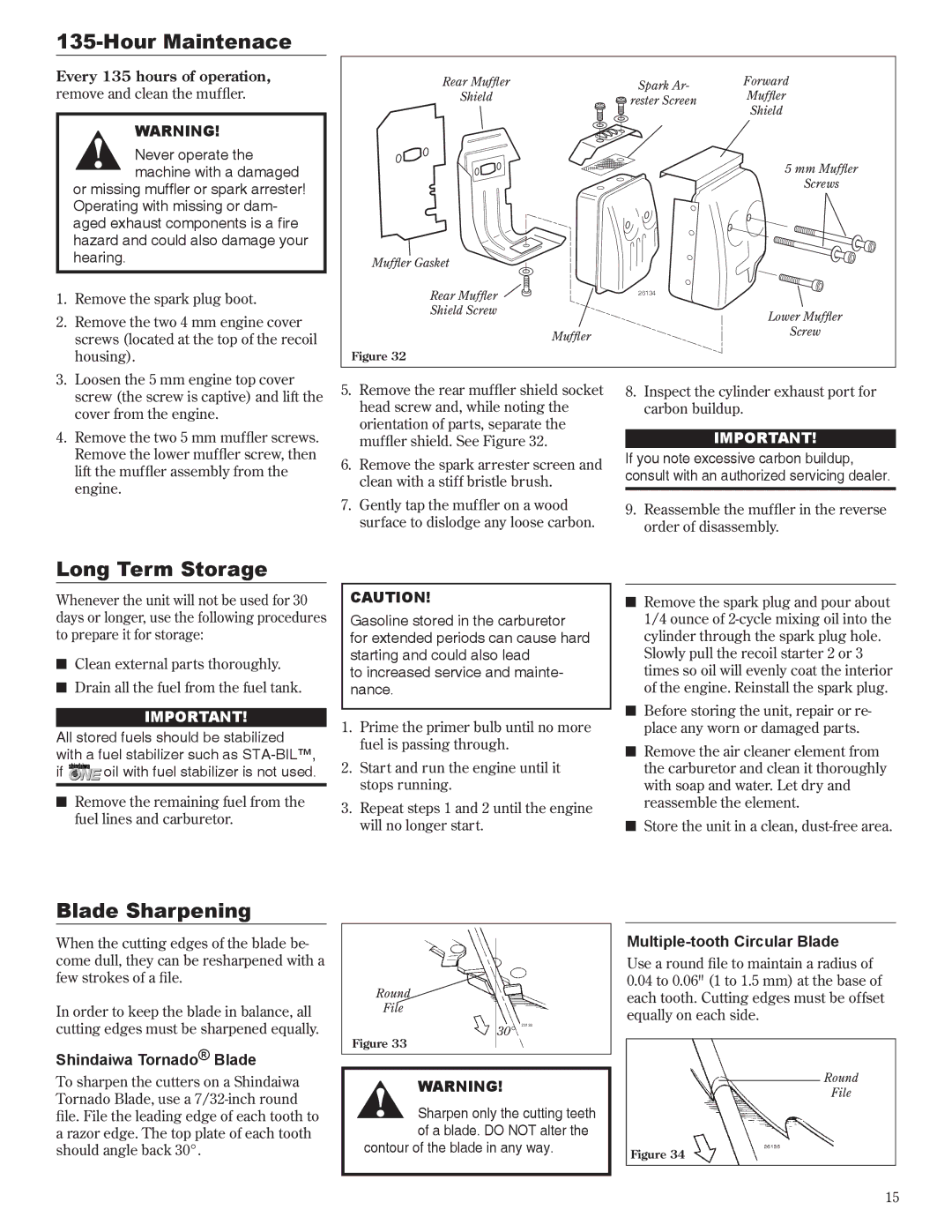

Rear Muffler |

| Spark Ar- | Forward |

Shield |

| Muffler | |

| rester Screen | ||

|

| Shield | |

|

|

| |

|

|

| 5 mm Muffler |

|

|

| Screws |

Muffler Gasket |

|

|

|

Rear Muffler |

| 26134 |

|

|

|

| |

Shield Screw |

|

| Lower Muffler |

|

|

| |

| Muffler |

| Screw |

|

|

| |

Figure 32 |

|

|

|

screw (the screw is captive) and lift the |

cover from the engine. |

4. Remove the two 5 mm muffler screws. |

Remove the lower muffler screw, then |

lift the muffler assembly from the |

engine. |

5.Remove the rear muffler shield socket head screw and, while noting the orientation of parts, separate the muffler shield. See Figure 32.

6.Remove the spark arrester screen and clean with a stiff bristle brush.

7.Gently tap the muffler on a wood surface to dislodge any loose carbon.

8.Inspect the cylinder exhaust port for carbon buildup.

IMPORTANT!

If you note excessive carbon buildup, consult with an authorized servicing dealer.

9.Reassemble the muffler in the reverse order of disassembly.

Long Term Storage

Whenever the unit will not be used for 30 days or longer, use the following procedures to prepare it for storage:

nClean external parts thoroughly.

nDrain all the fuel from the fuel tank.

IMPORTANT!

All stored fuels should be stabilized with a fuel stabilizer such as

if ![]() oil with fuel stabilizer is not used.

oil with fuel stabilizer is not used.

nRemove the remaining fuel from the fuel lines and carburetor.

CAUTION!

Gasoline stored in the carburetor for extended periods can cause hard starting and could also lead

to increased service and mainte- nance.

1.Prime the primer bulb until no more fuel is passing through.

2.Start and run the engine until it stops running.

3.Repeat steps 1 and 2 until the engine will no longer start.

nRemove the spark plug and pour about 1/4 ounce of

Slowly pull the recoil starter 2 or 3 times so oil will evenly coat the interior of the engine. Reinstall the spark plug.

nBefore storing the unit, repair or re- place any worn or damaged parts.

nRemove the air cleaner element from the carburetor and clean it thoroughly with soap and water. Let dry and reassemble the element.

nStore the unit in a clean,

Blade Sharpening

When the cutting edges of the blade be- come dull, they can be resharpened with a few strokes of a file.

In order to keep the blade in balance, all cutting edges must be sharpened equally.

Shindaiwa Tornado® Blade

To sharpen the cutters on a Shindaiwa Tornado Blade, use a

Round

File

30°

Figure 33

WARNING!

Sharpen only the cutting teeth of a blade. DO NOT alter the

contour of the blade in any way.

Multiple-tooth Circular Blade

Use a round file to maintain a radius of

0.04to 0.06" (1 to 1.5 mm) at the base of each tooth. Cutting edges must be offset equally on each side.

Round

File

Figure 34

15