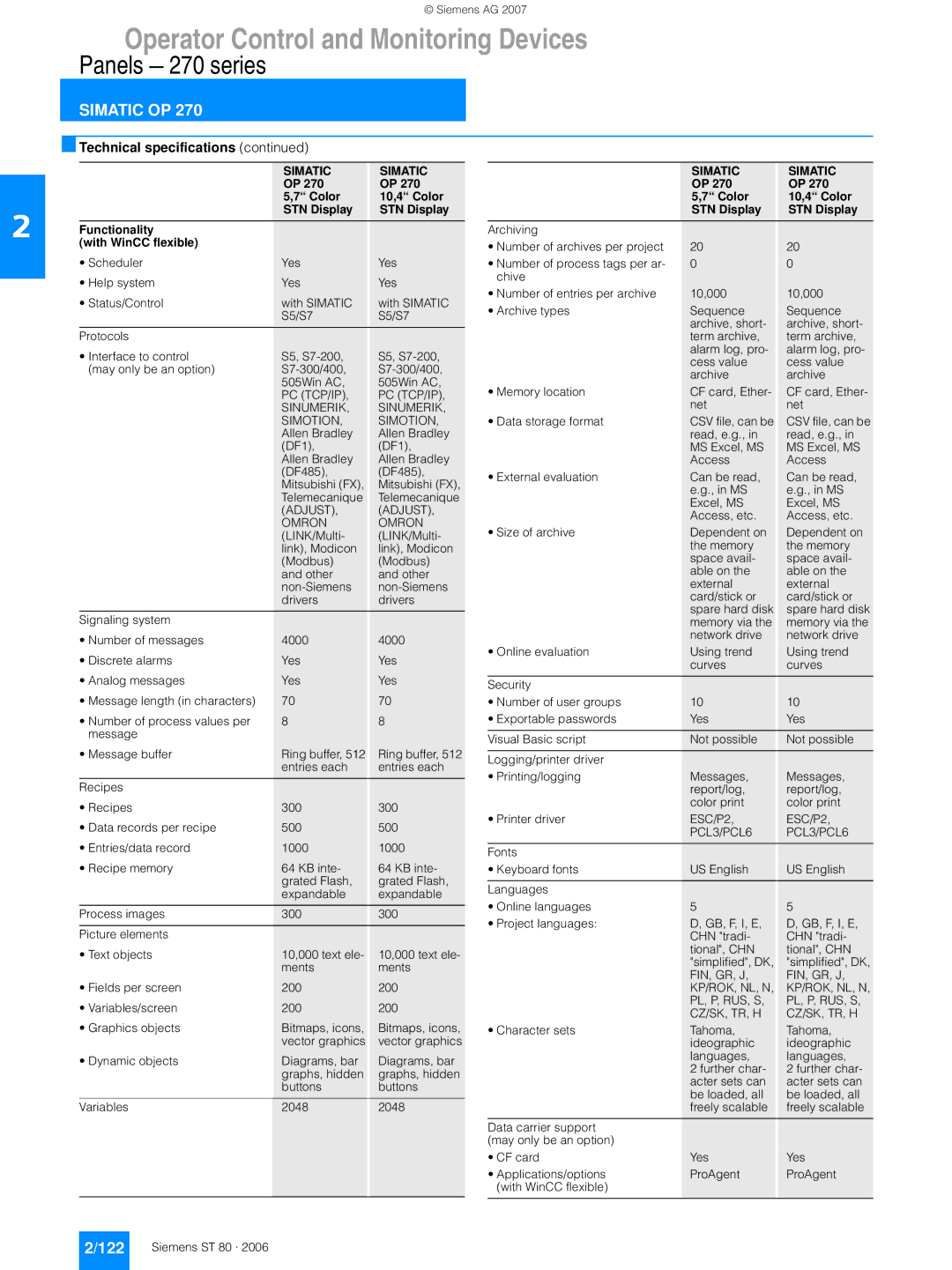

270 specifications

The Siemens 270 is a notable model in the landscape of industrial automation and control systems, designed to enhance efficiency and reliability in diverse applications. This versatile device is particularly recognized for its role in process automation, providing seamless integration of hardware and software.One of the main features of the Siemens 270 is its robust architecture, which supports a variety of input and output modules. This flexibility allows it to cater to a range of industries, from manufacturing to energy management. The system can handle multiple communication protocols, such as Profibus and Profinet, ensuring connections with various field devices and systems for streamlined data exchange. This interoperability is crucial for modern industrial environments where systems need to communicate across different layers of the automation pyramid.

The Siemens 270 boasts advanced processing capabilities, driven by high-performance CPUs that support real-time processing. This characteristic is essential for monitoring and controlling fast-paced industrial processes, where timely data analysis and response can significantly impact operational efficiency. Furthermore, the system is designed to handle complex algorithms and computations, which are necessary for tasks such as predictive maintenance and process optimization.

Another significant aspect of the Siemens 270 is its user-friendly interface. The integrated programming environment simplifies system setup and allows users to easily configure and monitor processes. This ease of use helps reduce training time for operators and ensures a quick response to any potential issues that might arise.

In terms of safety features, the Siemens 270 incorporates built-in redundancy options, enhancing the system's reliability and minimizing downtime. Safety protocols are integrated into the hardware and software components, enabling compliance with international safety standards. This is particularly important for industries where safety is paramount, such as chemicals or pharmaceuticals.

The Siemens 270 also emphasizes energy efficiency, with features that help monitor resource consumption and optimize energy use. This not only contributes to operational cost savings but also aligns with global sustainability efforts, making it an ideal choice for companies aiming to reduce their environmental footprint.

In conclusion, the Siemens 270 is a powerful tool in the realm of industrial automation, featuring advanced processing capabilities, flexible integration options, user-friendly interfaces, stringent safety standards, and a commitment to energy efficiency. Its multifaceted characteristics make it suitable for a wide array of applications, solidifying its position as a leader in the industry. As industries continue to evolve, systems like the Siemens 270 are equipped to meet the challenges and demands of tomorrow's automation landscape.