Safety Instructions (continued)

Perform proper functional checks and leak tests after maintenance.

Stop operation when an abnormality is observed such that the flow sensor does not work properly or there is a leakage of fluid. Safety is not be assured due to unexpected malfunction.

When leakage occurred from other parts except piping, the flow sensor might break.

Cut off power supply and stop supplying pressure. Don’t apply pressure at leaking condition.

Precaution on Handling

Use UL approved product for direct current power supply.

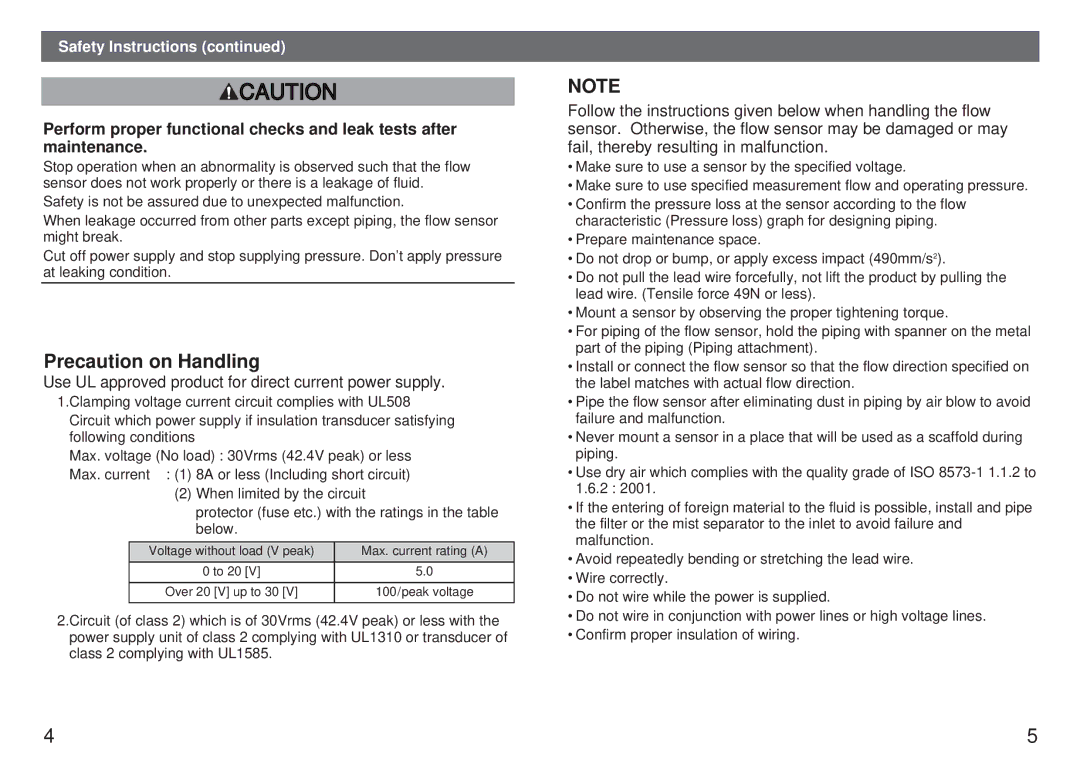

1.Clamping voltage current circuit complies with UL508 Circuit which power supply if insulation transducer satisfying following conditions

Max. voltage (No load) : 30Vrms (42.4V peak) or less

Max. current : (1) 8A or less (Including short circuit)

(2)When limited by the circuit

protector (fuse etc.) with the ratings in the table below.

Voltage without load (V peak) | Max. current rating (A) |

0 to 20 [V] | 5.0 |

|

|

Over 20 [V] up to 30 [V] | 100/peak voltage |

|

|

2.Circuit (of class 2) which is of 30Vrms (42.4V peak) or less with the power supply unit of class 2 complying with UL1310 or transducer of class 2 complying with UL1585.

NOTE

Follow the instructions given below when handling the flow sensor. Otherwise, the flow sensor may be damaged or may fail, thereby resulting in malfunction.

•Make sure to use a sensor by the specified voltage.

•Make sure to use specified measurement flow and operating pressure.

•Confirm the pressure loss at the sensor according to the flow characteristic (Pressure loss) graph for designing piping.

•Prepare maintenance space.

•Do not drop or bump, or apply excess impact (490mm/s2).

•Do not pull the lead wire forcefully, not lift the product by pulling the lead wire. (Tensile force 49N or less).

•Mount a sensor by observing the proper tightening torque.

•For piping of the flow sensor, hold the piping with spanner on the metal part of the piping (Piping attachment).

•Install or connect the flow sensor so that the flow direction specified on the label matches with actual flow direction.

•Pipe the flow sensor after eliminating dust in piping by air blow to avoid failure and malfunction.

•Never mount a sensor in a place that will be used as a scaffold during piping.

•Use dry air which complies with the quality grade of ISO

•If the entering of foreign material to the fluid is possible, install and pipe the filter or the mist separator to the inlet to avoid failure and malfunction.

•Avoid repeatedly bending or stretching the lead wire.

•Wire correctly.

•Do not wire while the power is supplied.

•Do not wire in conjunction with power lines or high voltage lines.

•Confirm proper insulation of wiring.

4 | 5 |