Service

DISCHARGE CHUTE WORM

ASSEMBLY ADJUSTMENT

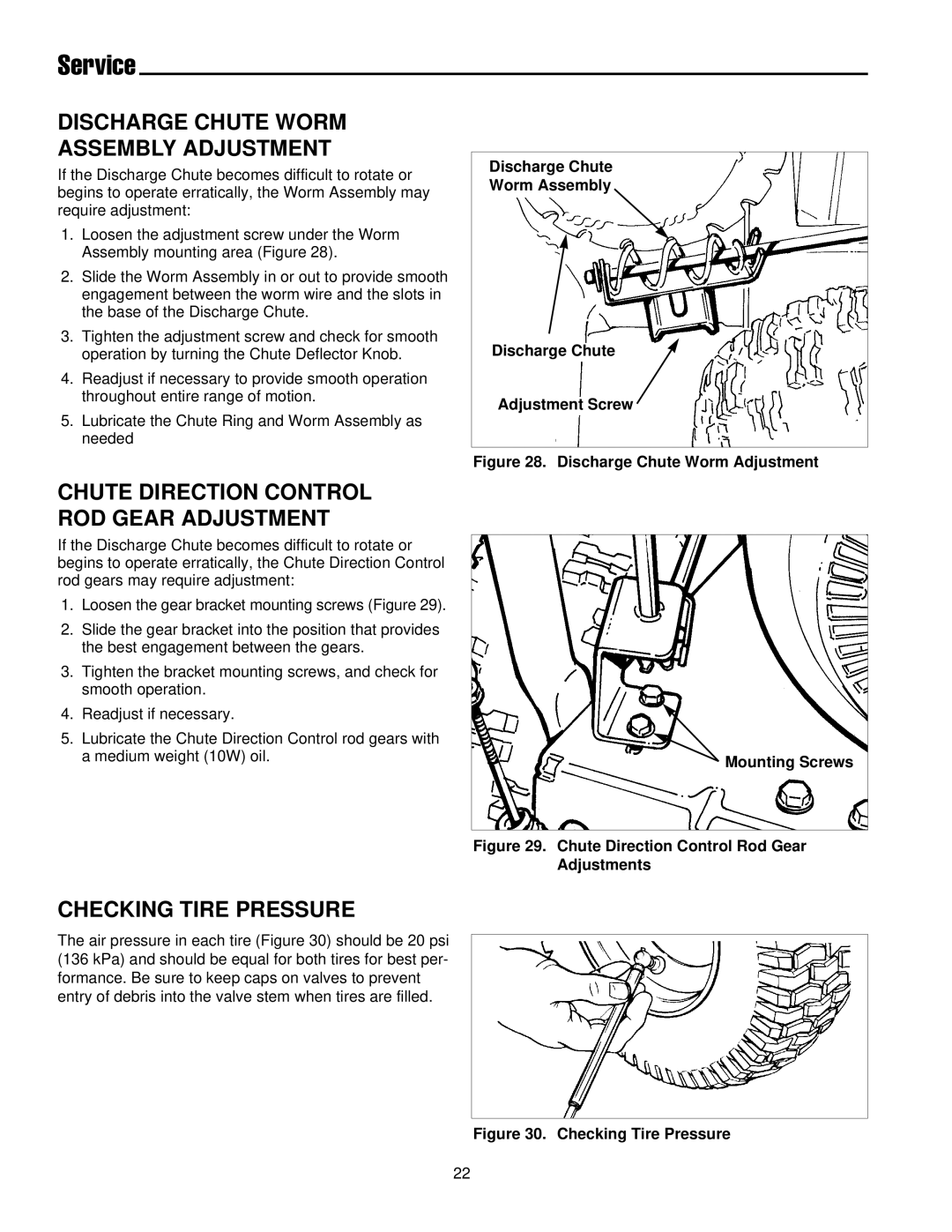

If the Discharge Chute becomes difficult to rotate or begins to operate erratically, the Worm Assembly may require adjustment:

1.Loosen the adjustment screw under the Worm Assembly mounting area (Figure 28).

2.Slide the Worm Assembly in or out to provide smooth engagement between the worm wire and the slots in the base of the Discharge Chute.

3.Tighten the adjustment screw and check for smooth operation by turning the Chute Deflector Knob.

4.Readjust if necessary to provide smooth operation throughout entire range of motion.

5.Lubricate the Chute Ring and Worm Assembly as needed

Discharge Chute

Worm Assembly

Discharge Chute

Adjustment Screw

Figure 28. Discharge Chute Worm Adjustment

CHUTE DIRECTION CONTROL ROD GEAR ADJUSTMENT

If the Discharge Chute becomes difficult to rotate or begins to operate erratically, the Chute Direction Control rod gears may require adjustment:

1.Loosen the gear bracket mounting screws (Figure 29).

2.Slide the gear bracket into the position that provides the best engagement between the gears.

3.Tighten the bracket mounting screws, and check for smooth operation.

4.Readjust if necessary.

5.Lubricate the Chute Direction Control rod gears with a medium weight (10W) oil.

CHECKING TIRE PRESSURE

Mounting Screws

Mounting Screws

Figure 29. Chute Direction Control Rod Gear Adjustments

The air pressure in each tire (Figure 30) should be 20 psi (136 kPa) and should be equal for both tires for best per- formance. Be sure to keep caps on valves to prevent entry of debris into the valve stem when tires are filled.

Figure 30. Checking Tire Pressure

22