CHECK TILLER TRANSMISSION GREASE

TILLER TRANSMISSION IS SHIPPED FROM FACTORY WITH THE PROPER AMOUNT OF 00 LIQUID GREASE.

Check the grease level annually. To check the grease level:

1.Move tiller to level ground.

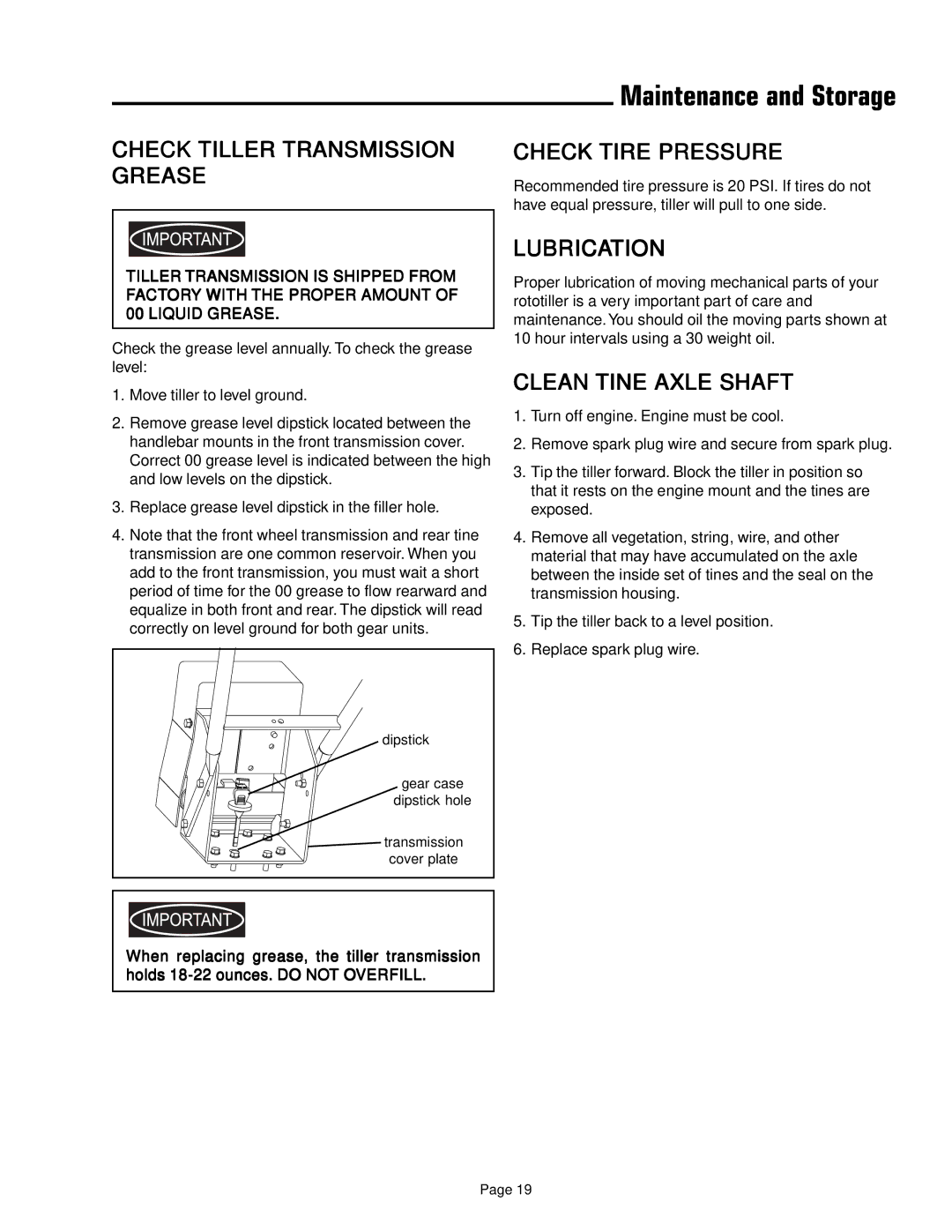

2.Remove grease level dipstick located between the handlebar mounts in the front transmission cover. Correct 00 grease level is indicated between the high and low levels on the dipstick.

3.Replace grease level dipstick in the filler hole.

4.Note that the front wheel transmission and rear tine transmission are one common reservoir. When you add to the front transmission, you must wait a short period of time for the 00 grease to flow rearward and equalize in both front and rear. The dipstick will read correctly on level ground for both gear units.

dipstick

gear case

dipstick hole

![]() transmission cover plate

transmission cover plate

Maintenance and Storage

CHECK TIRE PRESSURE

Recommended tire pressure is 20 PSI. If tires do not have equal pressure, tiller will pull to one side.

LUBRICATION

Proper lubrication of moving mechanical parts of your rototiller is a very important part of care and maintenance. You should oil the moving parts shown at 10 hour intervals using a 30 weight oil.

CLEAN TINE AXLE SHAFT

1.Turn off engine. Engine must be cool.

2.Remove spark plug wire and secure from spark plug.

3.Tip the tiller forward. Block the tiller in position so that it rests on the engine mount and the tines are exposed.

4.Remove all vegetation, string, wire, and other material that may have accumulated on the axle between the inside set of tines and the seal on the transmission housing.

5.Tip the tiller back to a level position.

6.Replace spark plug wire.

When replacing grease, the tiller transmission holds

Page 19